Frozen food processing and packaging is a vital industry that brings a world of convenience to consumers. It allows for longer storage of perishable goods, reduces food waste, and provides quick and easy meal solutions for busy lifestyles. As the global demand for frozen food continues to rise, the importance of maintaining the highest standards in processing and packaging has become paramount.

The History of Frozen Foods

For centuries, freezing has been a preferred method to preserve food all around the world. Still, only with a man named Clarence Birdseye from Gloucester, MA, have we obtained the way to optimize the process. Known as the “Father of Frozen Foods,” Clarence Birdseye had worked as a missionary, trapper, naturalist, and fur trader in Labrador. It was there that he recognized that fish caught while ice fishing would instantly freeze in the extreme cold temperatures of the far North. To his delight, he also noticed that fish and wild game frozen in this manner tasted better and lasted longer than those frozen at higher temperatures.

A Revolution in Food Preservation

It was in the early 1920s that he developed the first machine capable of quickly freezing foods, either as bulk pieces or in smaller packages. His invention made it possible to freeze foods in a process known as quick freezing. Retail-ready frozen foods for home consumption were first introduced in the early 1930s by the General Foods Corporation in 10 test food stores in Springfield, Massachusetts.

Trends and Consumer Preferences

Since then, there has been a rapid growth in sales of frozen foods due to year-round availability, consumer satisfaction, and the general convenience brought to the average consumer by frozen food products. Over the years and decades that followed, newer products and frozen food technologies were and still are being introduced to the market. The global frozen food market is now estimated at around $232.42 billion, and, by 2025, it is expected to get to $376.95 billion, with a compound annual growth rate (CAGR) of 4.3%.

From Meats to Bakery Products

From frozen meat to frozen bakery products, consumers with household refrigerators and freezers worldwide have recognized frozen food as a better choice among many other packaged products on store shelves. Importantly, the quality of frozen foods depends largely on the quality of the raw food and the manufacturing process. The quality can also be jeopardized if the product’s temperatures are not properly maintained throughout the entire cold chain. This includes storage, transport, distribution, and display in retail stores, alongside the processing and packaging of frozen foods. To that end, we’ve put together this introductory guide on some frozen food best practices.

The video below offers some insight into frozen food history.

The Freezing and Pre-Treatment Processes in the Frozen Food Industry

By and large, the freezing process consists of three stages; pre-treatment, freezing, and frozen storage. The pre-treatment may involve blanching, cryoprotection, dipping treatments, and heat treatments, depending on the food. The important fact here is that the freezing process only retains the quality that the food already has and will not improve it. So, the function of all pre-treatment processes is to maintain the safety and quality of frozen food.

Blanching Vegetables – Preserving Quality and Safety

For example, vegetables commonly undergo a blanching process via steam or hot water as a means of slowing down both the chemical and physical changes that can occur during storage. Fruits, however, are usually dipped in ascorbic acid or various sugar solutions to minimize browning. Meats and meat products, fish, and some vegetables will undergo heat treatments to kill surface microorganisms, as well as help them retain their initial firmness after thawing. New tools, technologies, and methodologies are constantly introduced to improve product quality and reduce costs.

Contact or Convection Freezing

The freezing process can be accomplished in several ways. One common method used in the frozen food industry is a variation of the old process first developed by Birdseye in the 1920s. This is an indirect contact process with a refrigerant that flows between belts or shelves that contain frozen food packages. This is known as contact or convection freezing.

Air-Blast Freezing

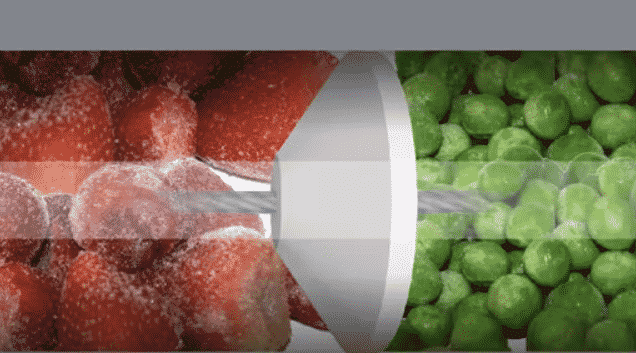

Another commonly-used method is through the use of cold air. Known as air-blast freezing, several methods fall within this category. Some involve belts, tunnels, or fluidized beds in which the food product is exposed to a free-flow current of freezing air at -30°F. In belt freezers, the unpackaged food is laid on a mesh belt through which the cold air is blowing.In fluidized bed freezers, the blast of cold air is strong enough to partially suspend the food. This method is particularly effective in achieving individually quick frozen (IQF) product pieces. These air-flow freezing techniques only take several minutes to achieve their intended purpose. Special precautions need to be taken to avoid dehydration and the transfer of moisture from the products to the walls and/or cooling coils.

Cryogenic Freezing

A third freezing method, commonly known as cryogenic freezing, has increased in popularity in recent years. This type of technology uses a super-cooled liquefied gas solution, such as liquid nitrogen or carbon dioxide, in which food items are sprayed with these liquids at temperatures of -320°F. The product is then equilibrated at -20°F and sent to storage. By shortening the freezing time from a few minutes to a few seconds, many products will retain a better texture after thawing. This method is typically used in small-scale operations, particularly at the early stages of product processing. Cryogenic freezers are also used for quick crust freezing of wet or otherwise sensitive products that can later be processed by contact or air-flow freezers.

What Is the Recommended Storage Temperature and Period?

Not all frozen foods have the same vulnerabilities in storage. These differences are primarily dependent on how quickly these foods develop abnormal flavors or discolorations. It’s also possible that different lots of the same type of food will have different stabilities based on various factors such as the initial quality of the raw product, ingredients, processing method, packaging materials, and more.

Storage life can be significantly increased as the storage temperature becomes colder. For the majority of products, a temperature of 0°F or below is required if the product is expected to be kept in storage for over six months. Storage temperatures that are above 0°F will accelerate quality losses.

The Time and Temperature Tolerance (TTT)

Time and temperature affect the frozen food’s overall quality (texture, color, and flavor). The food’s resistance to this degradation is known as the Time-Temperature Tolerance (TTT). Both regulations and company standards are used to ensure that the times and temperatures of stored frozen food products are within their tolerances. Compliance often entails significant costs, especially for products widely distributed or produced in large volumes. Nevertheless, frozen food manufacturers must maintain temperatures across the entirety of the cold chain to prevent consumer dissatisfaction.

The Practical Storage Life (PSL)

More commonly known as the shelf life, the practical storage life (PSL) represents the storage period of consumer acceptability. The general rule of thumb is that the colder the storage temperature, the longer the shelf life. For instance, raw and pre-cooked lean meats can be stored at 5°F for 4 to 20 months, depending on the product’s initial quality, processing method, and the packaging material used. However, if that temperature is lowered to -4°F for those same products, the average shelf life will increase to between 8 and 33 months. At -22°F, the practical storage life can even reach as much as 20 to 33 months.

On the other hand, fatty meat products have a shorter PSL than lean meats since high-fat content increases the likelihood of oxidation, rancidity, and off-flavors. As such, fatty meats have an average shelf life of about half of that of lean meats. The same thing can also be said about pre-cooked foods with gravy or fish products. Since these foods are more sensitive than red meats, they need to be frozen quickly and stored at colder temperatures to achieve similar shelf life.

Challenges in Storing Frozen Fruits and Vegetables

That said, frozen vegetables and fruits are the most sensitive products subject to storage deterioration, particularly when it comes to warmer frozen storage temperatures. At a storage temperature of about 23°F, these types of foods can only be stored for one to five months. It’s also important to note that these foods can also undergo slight thaws over time, losing fluids and nutrients. As storage temperatures are lowered, frozen fruit and vegetables become more stable. Nevertheless, it’s not recommended that temperatures go below -13°F.

Main Considerations for Frozen Foods Packaging

When packaging their products, frozen food manufacturers are faced with a complex set of FDA regulations and requirements that they need to meet. From aesthetic considerations to practical concerns, these factors are crucial for both preserving the quality of the food and meeting the expectations of consumers. That is why they need to satisfy several packaging needs:

- Customer appeal,

- Food safety,

- Tamper resistance,

- Leak resistance,

- Impermeability,

- Durability,

- Facilitation of rapid freezing,

- Resistance to -40°F temperatures,

- Convenience,

- Economy,

- Eco-friendliness.

In essence, these factors highlight the multi-dimensional demands placed on frozen food packaging. The challenge for manufacturers lies in finding a balanced approach that addresses all of these requirements. They need to comply with the FDA regulations for frozen food while also maintaining cost-effectiveness and environmental sustainability.

Frozen Foods Packaging and Sealing Technology

Vertical form fill and seal (VFFS) systems are the most popular solutions as they offer plenty of flexibility, great sealing effectiveness, reliability when subjected to external forces, and an overall hygienic design. The film (material) used in the packaging process is important because it protects the product and its visual appeal throughout processing on bulk material handling equipment, storage, thawing, and, in some cases, cooking.

Selection of Packaging Material

Many frozen food producers will use a polyethylene (PE) film because it offers a high level of durability, puncture resistance, and shelf life. Aluminum foil laminates were also shown to perform well in oxygen permeability, mechanical and thermal stability, water transmission, and sealing durability. The production system needs to be compatible with the desired film, as too much friction during the packaging process can affect the quality of the end product.

Sealing Technology Choices

The sealing technology used needs to be appropriate for the chosen packaging material. An effective seal will not only ensure quality and protection against external forces and gases but will also improve the packages’ appearance. For thicker films, such as polypropylene (PPE), direct heat sealing is ideal. However, impulse heat sealing or VFFS systems are also great alternatives. A relatively new entrant is zip-lock technology, which has gained increased popularity in recent years due to the convenience and visual appeal it provides to consumers. It can be used in combination with a heat-sealing method.

Food Safety in Frozen Food Processing and Packaging

Safety standards in the frozen food industry are among the highest in the country. That’s especially true regarding sanitation and cleaning procedures. All producers must have the electrical system and equipment designed to withstand dust and aggressive wet cleaning, internal and external alike.

As a general rule for safety and quality optimization, frozen food producers should use a hygienically-designed packaging system that makes the entire cleaning process as easy and seamless as possible. Stainless steel VFFS systems, for example, are specifically designed to have sloping surfaces to eliminate product buildup of food residue. Not only will these systems enable easier access for cleaning and maintenance, but they also prevent cross-contamination. It’s also a good practice to maximize throughput speeds to transport products quickly to prevent any unwanted thawing.

Temperature Fluctuations and Their Impact on Frozen Food Quality

To maximize frozen food production, manufacturers need system integration. All systems and components of the frozen food manufacturing process need to communicate efficiently. Generally, short periods of temperature fluctuations are not a serious concern as long as they are not repeated. It’s important to keep in mind that the loss of frozen food quality is gradual, cumulative, and irreversible. With particularly sensitive products, even a short exposure to relatively warm temperatures of 10 to 15°F can result in a marked loss in quality.

Such temperature fluctuations also need to be avoided since they can cause the migration of moisture from the product, which will result in dehydration and the formation of ice crystals. Typically, the ambient temperature is not as important as the temperature of the product. A very brief change in air temperature will not have a significant effect on the food’s temperature.

Refrigeration in Frozen Food Transportation

Refrigeration equipment used in the transportation of frozen foods is designed to counteract any heat that may leak into the load compartment, be it a truck, container, or railcar. However, it’s important to note that the refrigeration capabilities of these systems will not be able to remove excess heat from the load. Frozen food products need to be loaded at a temperature of 0°F or lower before loading because there is very little to no opportunity for the food’s temperature to be lowered during transit. The same principle applies to retail display equipment, which will be unable to quickly lower the temperatures of frozen products. That’s why frozen foods must be kept at 0°F or lower throughout storage, transport, and display.

Overlooking Conveyor Systems

Equipment that many frozen food producers tend to neglect is the conveyor systems used for the transport of frozen foods through their facilities. These systems need to adhere to all the safety and quality standards of the other freezing and packaging equipment. In addition, they need to eliminate the risk of cross-contamination and minimize product loss during transit.

Frozen Food Processing and Packaging Simplified With Cablevey Conveyors

Cablevey’s frozen food belt conveyor system is suitable for all sorts of food batch ingredients and finished products in a gentle, safe, and sanitary manner. Materials used in the construction of these systems include alloy 304 stainless, optional 316 stainless, and food-contact grade engineering plastics. First of all, these types of conveyors help reduce the incidence of black specks occurring on the product, which is a big quality concern when it comes to other types of conveyors. The wet and dry cleaning options available enable each facility to optimize its sanitization protocols.

Cable and tube conveyor systems also eliminate the issues of product spillage and warming, which is often a problem with other system types such as buckets, pneumatic conveyor systems, screw augers, or any type of conveyor belt system. Cablevey’s frozen food conveyor systems are offered in a wide variety of different sizes and offer a full scope of different components. This means that they can be optimized to cover any facility layout and frozen food conveyor movement needed to shorten the time that the frozen food products will be outside of their optimum temperature.

Ready to optimize your frozen food production process with an efficient industrial conveyor belt for the warehouse or a tubular custom conveyor belt for food? Contact us today to customize a solution that perfectly suits your facility layout and minimizes product exposure to suboptimal temperatures.