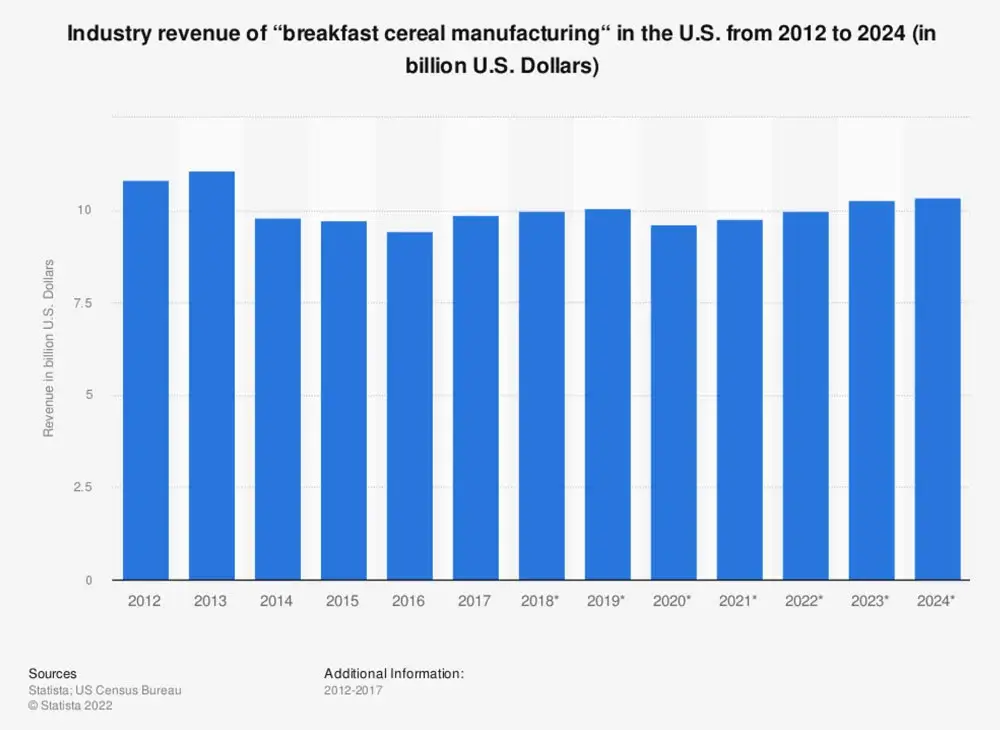

Cereal is the top breakfast choice for Americans, and therefore, breakfast cereal industry trends for 2023 need to be monitored. In 2022, the breakfast cereal market was valued at $10 billion and is expected to reach $10.34 billion by 2024. To prevent damage to the cereals, gentle transport is essential. As the industry expands, it’s vital for facilities to strategize for this growth, taking into account the specific needs for transporting cereals.

Businesses Need to Adapt Their Processing Facilities to Accommodate Industry Growth

In October 2022, Cablevey Conveyors partnered with the independent research group Ascend2 to initiate a study called Assessing and Adopting New Conveyor Systems. This comprehensive 16-page report, available for free download, surveyed 290 professionals in the food processing sector from the US and UK, seeking their perspectives on pivotal aspects of automated conveyor systems evaluations.

In this article, we will review and analyze the findings from 135 food processing professionals who are conveying breakfast cereal. What are they doing to prepare for growth? Use these findings and download the report for more information to help prepare for what is ahead in the breakfast cereal industry.

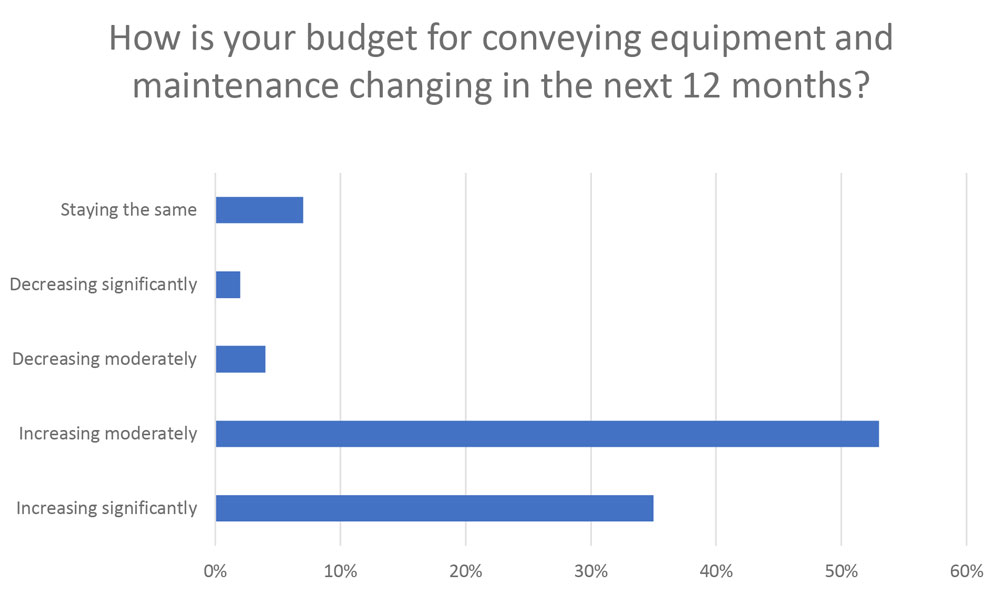

The First Finding – Preparing Financially for Growth

A significant 88% of breakfast cereal processing facilities plan to boost their budget for conveyor technologies and upkeep in the coming year. Moreover, 35% indicate a substantial budget hike to address growth prospects. The industry’s growth, accelerated post-pandemic, is forecasted to persist for the next five years or more.

Why the Increase in the Budget?

The uptick in allocation stems from the significant expansion these enterprises witnessed over the previous year. A remarkable 72% of facilities saw a growth of 11% or higher in that duration. Given such expansion, it’s essential for facilities to strategize for enhanced conveyor capacity for breakfast cereals, aligning with the surge in demand.

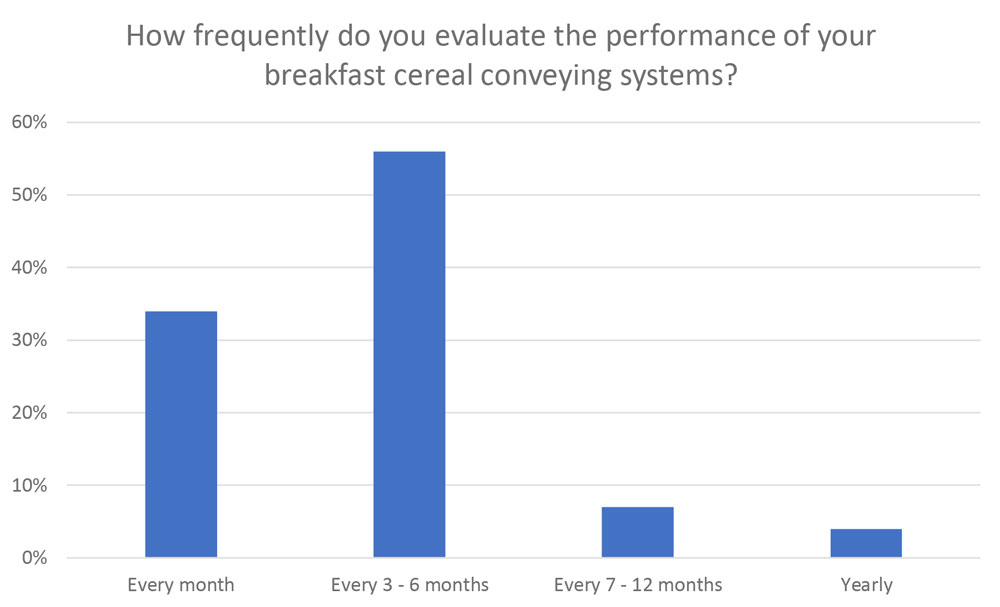

The Second Finding – How Often Should You Assess Your Conveyor Systems?

Regularly checking the efficiency of your conveyor systems is crucial. How often should you review your systems for breakfast cereal conveyance? A notable 90% of the experts questioned conduct evaluations at a minimum of twice a year, while 34% do so every month.

And when the evaluation process results in a purchase, who is involved in the decision-making process? It is a collaborative process that includes in-house engineers, outside consultants, maintenance personnel, and local equipment representatives. 42% say that each of these groups is involved in the process.

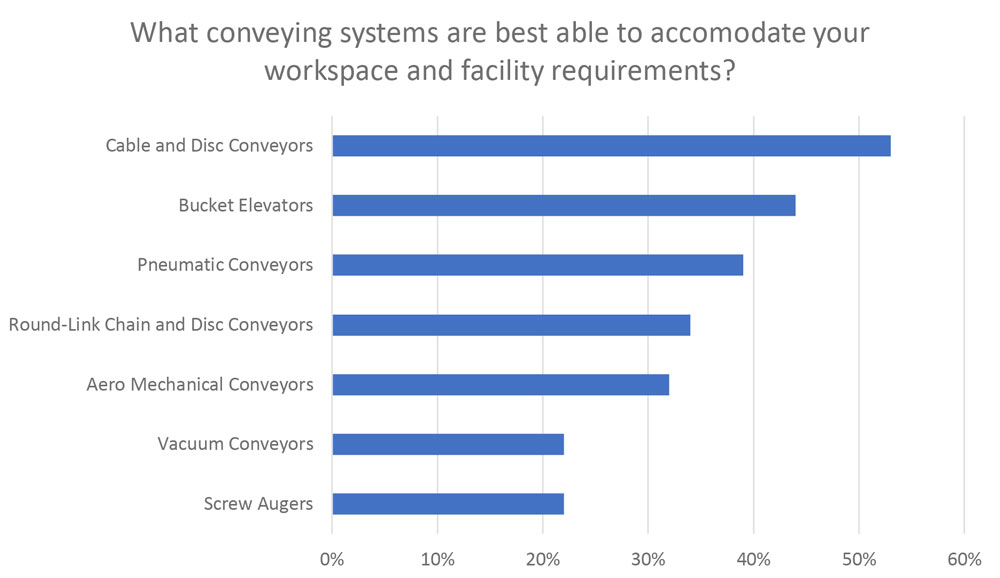

Third Finding – What Type of Conveying System Optimizes a Facility’s Workspace?

A key aspect of expansion is assessing your facility and workspace needs. Which conveyor systems are ideal for the space you currently possess? Are you making the most of the available area?

A whopping 97% of experts in the breakfast cereal sector mentioned they’re fine-tuning their facilities and workspace needs. What’s their approach? Based on the feedback from these professionals, cable and disc conveyors are the top choice (53%) for capitalizing on existing space.

How to Determine the Right Conveyor System for Your Workspace?

When determining whether to upgrade your conveyor system or invest in a new one to make the most of your facility’s space, consider the following questions:

- Is there adequate ground area or overhead clearance for specific conveyor models?

- Does the conveyor design factor in straightforward access for upkeep and cleaning, employee safety, and efficient functioning?

Check out this brief video, which showcases a conveyor system for breakfast cereals, highlighting methods to maximize space, ensure product integrity, and maintain high quality.

What Makes a Tubular Conveyor a Preferred Choice?

Cablevey’s tubular drag-type conveyors are crafted to utilize straightforward pneumatic tensioning for the cables, ensuring minimal upkeep. Moreover, their design facilitates effortless cleaning, with methods in place to streamline the process, enhancing productivity and minimizing disruptions.

How Are Tubular Conveyors Cleaned?

For Cablevey’s conveying machinery, there are wet, dry, and in-line cleaning methods at your disposal. Cablevey’s design and support team collaborates with breakfast cereal specialists to identify the optimal cleaning approach tailored to unique demands and criteria.

Fourth Finding – The Optimal Approach to Preserving the Quality of Breakfast Cereal During the Conveying Process

Cereals necessitate delicate transportation due to their composition of ingredients like nuts, grains, dried fruits, and others that are susceptible to factors such as:

- Heat,

- Moisture,

- Sudden drops,

- Shaking.

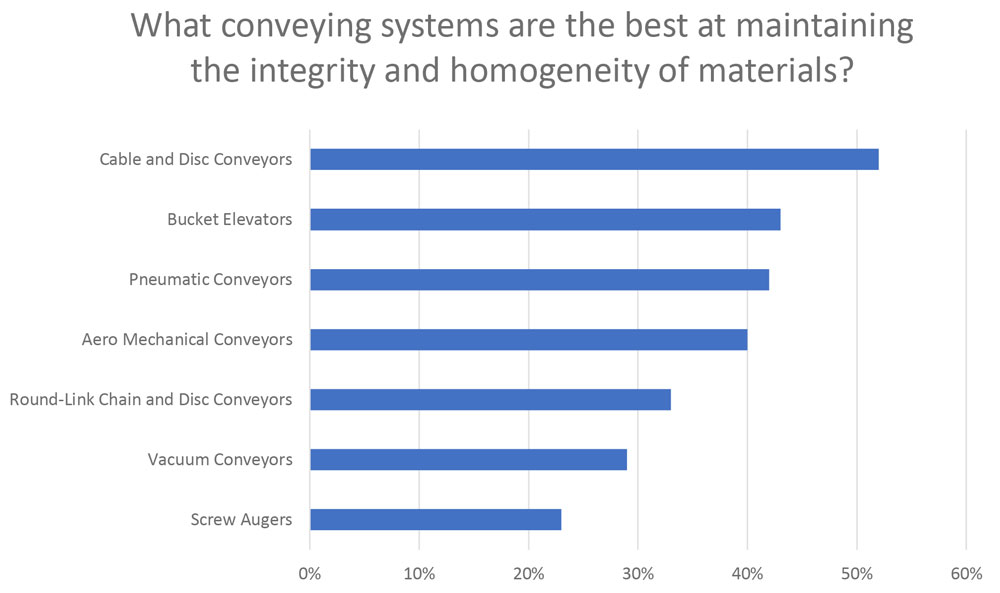

Which method is top-rated by experts in the breakfast cereal sector for preserving cereal quality? Cable and disc conveyors lead the pack with a preference rate of 52%.

How to Pick the Right System Based on This Factor?

When considering a conveyor system with product quality in mind, ponder over these two questions:

- Does the system prioritize cleanliness without causing extensive operational pauses?

- Will the system handle your products delicately to prevent damage and reduce wastage?

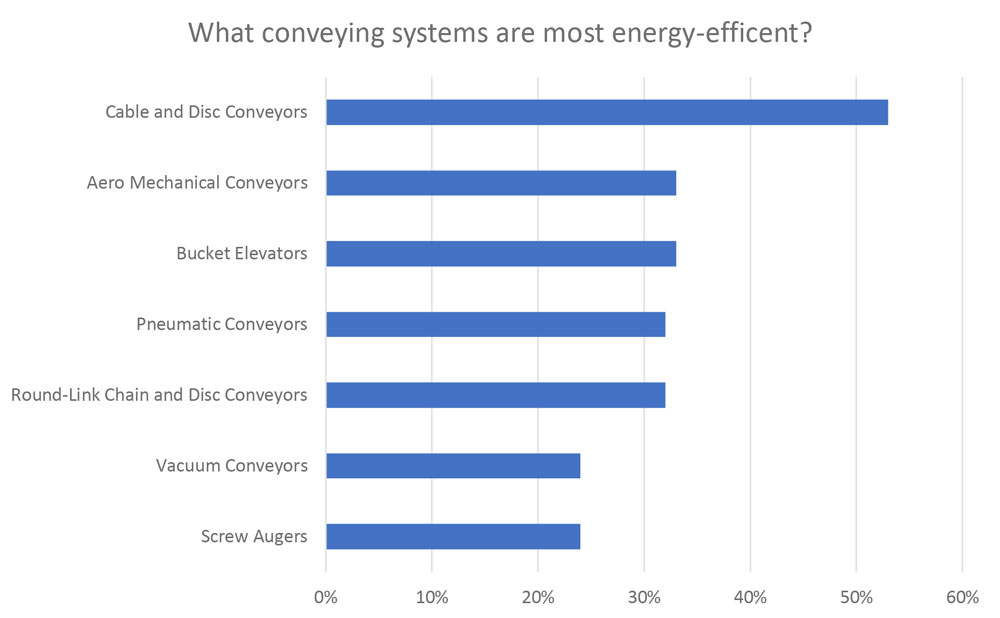

Fifth Finding – Energy Efficiency Shouldn’t Be Forgotten

What factors into energy efficiency? The motor’s size and the horsepower needed to operate a conveyor system can significantly influence operational expenses. Which conveyor system offers optimal energy efficiency for breakfast cereals? Cable and disc conveyors stand out, leading by a significant difference at 53%.

When deliberating on power consumption and efficiency, consider questions such as:

- What’s the energy consumption of this system?

- Is there a specific threshold where the system’s efficiency diminishes, be it high or low?

Final Verdict on Breakfast Cereal Industry Trends for 2023

The breakfast cereal industry is on an upward trajectory and undergoing changes. This study sheds light on the detailed strategies industry experts employ to anticipate this growth and make optimal choices for their operations.

The findings highlight cable and disc conveyors as the prime choice for cereal processing plants. These conveyors use a coated, bendable stainless steel drag cable in a looped mechanism. Attached to the cable are solid discs that ensure the even distribution of cereal components, preserving the desired mix and preventing separation common in other conveyor systems.

Furthermore, these discs guide the cereal through the tubing without using air or excessive pressure, safeguarding the product’s integrity. The closed-off nature of the tube reduces dust, offering a cleaner, more secure production environment and minimizing the risk of contamination.

Opt For Cablevey Conveyors

Minimize waste, safeguard against damage, and ensure optimal breakfast cereal production using Cablevey tubular drag conveyors. To determine if Cablevey’s system aligns with your conveying needs, let the Cablevey Testing Center conduct a complimentary evaluation for you. This center will furnish data to guide your decision-making tailored to your unique requirements. Contact us and remember to ask for conveyor installation supervision from us so that everything works smoothly.