Cablevey Case Studies

Internationally Acclaimed Coffee Roasting Supply Company Relies on Cablevey for Gentle Conveyance

Cablevey’s conveyor solutions are integral to the success of an international coffee roasting supply company such as Probat Inc. Renowned for their meticulous approach to preserving the integrity of beans,

Wild Bird Seed Provider Develops New Blends Due to Cablevey Conveyor Selection

Explore how Nutropica, a leading wild bird seed provider, develops innovative new blends due to Cablevey conveyor selection. The company’s new conveyor solutions enabled the seamless integration of diverse ingredients,

Brazilian Coffee Roaster Plans for Future Growth With Cablevey Conveyor Installation

Orfeu, a Brazilian coffee roaster, plans for future growth with Cablevey conveyor installation. This move underscores its commitment to enhancing operational efficiency and product quality in the competitive coffee industry.

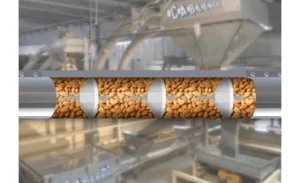

International Almond Processor Selects Cablevey to Reach Food Safety Goals

In a significant move towards improving its production process, an international almond processor selects Cablevey to reach food safety goals. This collaboration marks a pivotal step for Almendras Llopis in

Tubular Conveyor Protects Delicate, High-Value Products Like Nuts, Cereal, Snacks, and More

In the competitive world of food processing, learning how a tubular conveyor protects delicate products is a must. After all, all reliable conveyor manufacturers want to offer conveyor engineering solutions

Quick, Compact Installation and Flexible Design Attracts Brewer to Cablevey Tubular Conveyor

Explore this case study to discover how quick, compact installation and flexible design attracted a brewer to Cablevey and its tubular conveyor. This innovative conveying solution perfectly addresses the unique

Craft Brewer Trusts Cablevey Conveyors for Gentle Product Handling of Fragile Grains

In an industry where precision is paramount, every craft brewer trusts Cablevey Conveyors for gentle product handling. Our cutting-edge tubular conveying systems are specifically engineered for the delicate transfer of

Cablevey Conveyors Prevents Contamination for Pet Food Processors

In the realm of pet and animal food production, the journey from raw materials to packaging demands meticulous attention to hygiene and product integrity. Recognizing these critical needs, Cablevey Conveyors

Cablevey Earns a Reputation for Excellence With a Major Pet Food Manufacturer

Cablevey earns a reputation for excellence with a major pet food manufacturer, showcasing an unparalleled ability to meet the demanding needs of the pet food industry. Our innovative conveyor solutions

Rice Processor Improves Sanitary Product Transport With Enclosed Tubular Conveyor

When it comes to the conveying process, is there an innovative solution that offers a dust-free environment and ensures the highest standards in rice handling? Explore how Novarozz, a rice

Nut Grower Swaps Out Bucket Conveyor for Tubular System to Cut Losses and Speed Cleaning Times

In a strategic move to enhance efficiency and reduce waste, Hamilton Ranches, a prominent nut grower, swaps out a bucket conveyor for a tubular system designed by Cablevey Conveyors. This

Enclosed Tubular Conveyor System Eliminates Breakage for Premier Coffee Roaster

In today’s fast-paced coffee manufacturing environment, ensuring the seamless transport of ingredients is crucial for operational efficiency and product quality. Stick around to explore how Cablevey’s enclosed tubular conveyor eliminates

Almond Processor Achieves Gentle Conveyance With an Equipment Upgrade

In a strategic move to enhance its operational efficiency, Hilltop Ranch, an almond processor, achieves gentle conveyance with an equipment upgrade from Cablevey Conveyors. This upgrade, focusing on the delicate