Explore this case study to discover how quick, compact installation and flexible design attracted a brewer to Cablevey and its tubular conveyor. This innovative conveying solution perfectly addresses the unique demands of the brewing industry, offering an efficient, space-saving method for transporting ingredients. The Cablevey tubular conveyor’s adaptability and minimal footprint make it an ideal choice for facilities looking to optimize their operations without compromising on quality or performance.

Why The Bruery Opted for Cablevey’s Tubular Conveying System

“Coming from Orange County, we have a challenging physical location. Industrial space is very expensive, and we needed a system that could handle some decently tight sweeps, that could actually carry the grain a far amount of distance and could be installed fairly quickly,” says Jim Mellem, Director of Operations for The Bruery, located in Orange County, California.

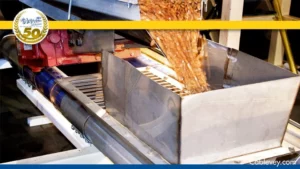

In order to solve these challenges, The Bruery integrated Cablevey’s grain conveyor systems, which have a flexible design and are well-suited for shuttling all types of brewery materials, including grain and mash. These industrial conveyor systems can be configured to meet the needs of any part of the production process.

Tubular Cable and Disk Conveyor Is the Best Choice for Breweries

Engineered to move both wet and dry grains, these systems utilize cables and discs to move materials along their transportation paths gently and reliably. The system is designed to run on a low horsepower motor using less energy than competing conveyors, making it more cost-effective in the long run.

Breweries looking to scale operations to meet demand are discovering that they have a confusing array of not-really-suited-for-long-term options for expanding their production apparatus – starting with screw augers that compromise the quality of their grain. Enclosed tubular cable and disc conveyors offer efficiency for moving materials safely within their unique production environments.

The Bruery Is More Than Satisfied With Their New Conveyors From Cablevey

Mr. Mellem is happy with the Cablevey Conveyors and their systems installed at The Bruery, saying, “The Cablevey has been a very reliable and gentle system. There is no deterioration of the grain either in the whole form or after the mill. It’s basically nothing but good malt going into good beer, which is fantastic for brewers. It’s exactly what we want.”

Cablevey Conveyors is a member of the Brewers Association. We understand the unique needs of this specialized industry. Our conveyor solutions for barley, rye, and other specialty grains have assisted in the growth of the booming US craft beer market. To learn more about how the Cablevey grain conveyor system is utilized on a brewery floor, be sure to check out our videos.

Why Opt for Cablevey Tubular Conveyor – No Matter What You’re Processing

Choosing Cablevey Conveyors for your processing needs, regardless of the material that you need to convey, guarantees a superior quality conveying solution that stands out in the industry. These systems, meticulously designed and manufactured by our expert team at Cablevey Conveyors, epitomize efficiency, reliability, and the gentle handling of products, ensuring that everything from grains to powders and pellets is moved with the utmost care.

What sets us apart is our commitment to precise conveyor engineering and innovation. Each tubular cable and disk conveyor is tailored to meet the specific requirements of the material it handles, minimizing product degradation and loss. The enclosed design of these conveyors not only preserves the integrity of the product but also significantly reduces cross-contamination and dust generation, making them an ideal choice for industries where hygiene and cleanliness are paramount.

Furthermore, Cablevey Conveyors places a strong emphasis on customization and flexibility. Our tubular cable and disk systems can navigate complex routes and multiple elevation changes, seamlessly integrating into existing production environments without the need for extensive modifications. This adaptability, combined with low maintenance requirements and operational efficiency, makes Cablevey’s tubular cable and disk conveyors an unmatched solution for a wide range of processing applications.

Contact Us at Cablevey Conveyors, and Let’s Work Together to Improve Your Production Process

Reaching out to Cablevey Conveyors is the first step towards revolutionizing your production process. Our team is dedicated to understanding the unique challenges and requirements of your operation, offering tailor-made solutions that enhance efficiency, maintain product integrity, and ensure the highest levels of hygiene.

With our advanced tubular cable and disk conveyor technologies, we promise seamless integration into your existing setup, minimal product waste, and a significant reduction in downtime. Our commitment to innovation, quality, and customer satisfaction makes us the ideal partner for your conveying needs. Let’s collaborate to optimize your production process, reduce operational costs, and achieve your business objectives. Contact us today, and together, we can elevate your production to new heights.

FAQ

How Does the Cablevey Tubular Conveyor System Address the Unique Needs Of Breweries?

The Cablevey tubular conveyor system is designed with flexibility and space efficiency in mind, making it perfect for breweries facing physical location challenges. Its ability to transport materials over distances quickly and reliably meets the demanding requirements of brewery operations.

What Makes Cablevey’s Tubular Cable and Disk Conveyors Stand Out for Grain Transport?

Cablevey’s tubular cable and disk conveyors utilize a gentle conveying method that prevents grain deterioration, ensuring high-quality malt goes into brewing. The system’s low horsepower motor usage reduces energy costs, making it a cost-effective solution for breweries.

Why Are Enclosed Tubular Cable and Disk Conveyors Preferred Over Other Options?

Enclosed tubular cable and disk conveyors offer superior efficiency and safety for moving brewery materials. Unlike screw augers, which can compromise grain quality, these systems ensure the integrity of grains, contributing to the production of high-quality beer.

How Satisfied Are Customers With Cablevey Conveyors’ Systems?

Customers like The Bruery have expressed high satisfaction with Cablevey’s systems, praising their reliability, gentle handling of materials, and contribution to producing quality beer. The system’s effectiveness in preserving grain integrity is particularly valued.

Why Choose Cablevey Conveyors for Your Processing Needs?

Opting for Cablevey Conveyors ensures superior quality conveyor solutions that are efficient, reliable, and gentle on products. The customization and flexibility of tubular cable and disk conveyors, along with their emphasis on precise conveyor engineering and innovation, make them ideal for a wide range of industries.