One of the main concerns in industries that handle food and other perishable and delicate materials is the sanitation of the belt conveyor system. To overcome contamination and other safety issues, Cablevey Conveyors have developed a conveyor monitoring system camera as a diagnostics and preventive measure tool. By offering a lens into the most critical points in the transit process, this camera system allows for timely interventions, effectively reducing the risk of contamination and other safety breaches.

Cablevey Conveyor’s Role in the FSMA Era

The early 2000s saw numerous incidents of foodborne illnesses that jeopardized public health, and such contamination cost the food industry billions of dollars in revenue. As a result, the Grocery Manufacturers Association helped craft the Food Safety Modernization Act (FSMA). President Barack Obama signed it on January 4, 2011. The FSMA mandates stricter standards and practices in the way in which food is handled, transported, and processed. Cablevey Conveyor’s preventative inspection system cameras ensure that the tubular drag conveyors used in food processing remain clean of cross contaminants, keeping food safe and helping manufacturers remain compliant with FSMA regulations.

Why Was This Preventive Measure Developed?

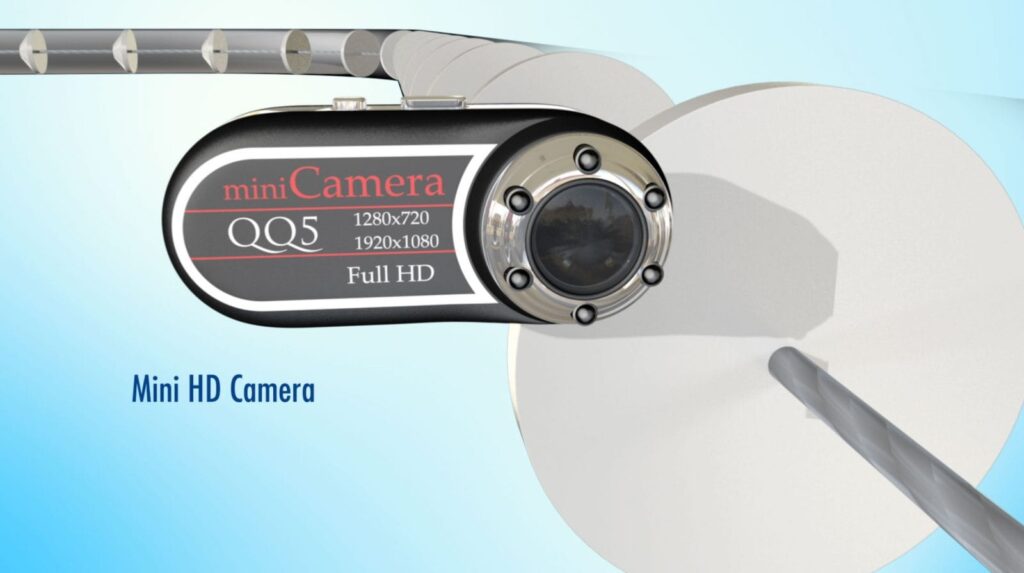

Engineers at Cablevey developed the mini-HD inspection camera as a diagnostic tool to be used during a preventative maintenance cycle so that operators can inspect empty tubular drag systems and verify that conveyors are installed correctly. Designed for easy installation, the unit’s assembly is attached to the cable as two disc halves that firmly grip and move with the cable – an innovative travel system that allows a camera to run the length of an empty tube. Each camera contains a removable micro SD card and self-contained LED lighting units, and the video is formatted for compatibility with any standard computer. Once inspection of the system is complete, the camera can be easily removed.

Elevate the Sanitation of Your Conveyors

The mini-HD inspection camera ensures tubes are clean and free of built-up material, making it an ideal asset for food processing facilities and applications that require a high level of sanitation. Remote camera access allows either operators or Cablevey’s technicians to view the system interiors and evaluate them for weaknesses, such as dented or misaligned pipes. Maintenance issues can now be diagnosed within a few minutes, either on-site or from Cablevey’s offices, without the need to disassemble the conveyor.

Conveyor Monitoring System Camera Is a Perfect Prevention Measure

A little more than a decade ago, the food industry faced billions in losses due to recalls, legal actions, and lost sales as a result of tainted products making their way into circulation. Vigilant inspection of tubular drag conveyor systems is a preventative measure to assist in the safeguarding of food against dangerous contamination. By keeping a watchful eye on activity, operators can respond with the proper steps so that potentially unhygienic food never reaches the public.

A Conveyor Monitoring System Camera Ensures Food Safety

Cablevey Conveyors has taken a big step in ensuring food safety with our conveyor monitoring system camera. This smart tool watches over food items as they move along the conveyor belt system, helping to prevent contamination. It blends hygiene with technology, setting a new benchmark in the food industry. With this system, each piece of food that reaches the consumer is both safe and high quality, building greater trust in the food sector.

Harnessing Technology for Elevated Food Safety

The conveyor monitoring system camera by Cablevey Conveyors is a tool designed to oversee the proper handling and transportation of food items. Below are some of the key benefits of using this groundbreaking technology:

- By keeping a close watch on food items as they move, the system helps in averting potential contamination, ensuring purity in every product that passes through the conveyor.

- The camera acts as a vigilant guard, constantly monitoring the transportation process and helping to uphold high safety standards.

- This tool offers the advantage of real-time monitoring, allowing for timely interventions if any irregularities are detected.

- Consumers can have greater confidence in the quality and safety of their food, fostering a stronger bond of trust between manufacturers and consumers.

- With this system in place, the journey of food products is more transparent and managed efficiently, ensuring that standards are maintained throughout the process.

A conveyor monitoring system camera isn’t just an investment in technology but a step towards safer and healthier food production.

With Cablevey Conveyors, Safety and Quality Comes First

Cablevey’s conveyor monitoring system cameras help food manufacturers comply with FSMA legislation. That way, both consumers and producers in the food supply chain are protected from the hazardous and costly consequences of contaminated food. But our pledge to safety goes beyond compliance – it extends to delivering solutions that redefine industry standards. Our custom conveyor belt for food is crafted to meet the unique demands of food handling and transportation. Furthermore, our industrial conveyor belt for the warehouse and other bulk material handling equipment guarantees an optimized, safe, and efficient solution.

By choosing Cablevey, you are not just opting for a conveyor system – you are investing in a promise of excellence, where innovation meets responsibility. We offer you an unrivaled guarantee of safety and quality. To learn more about Cablevey’s innovations for tubular drag and cable conveyor systems, check out Cablevey today!