Compare Conveyor Systems

Cablevey Conveyors vs. Other Conveyors

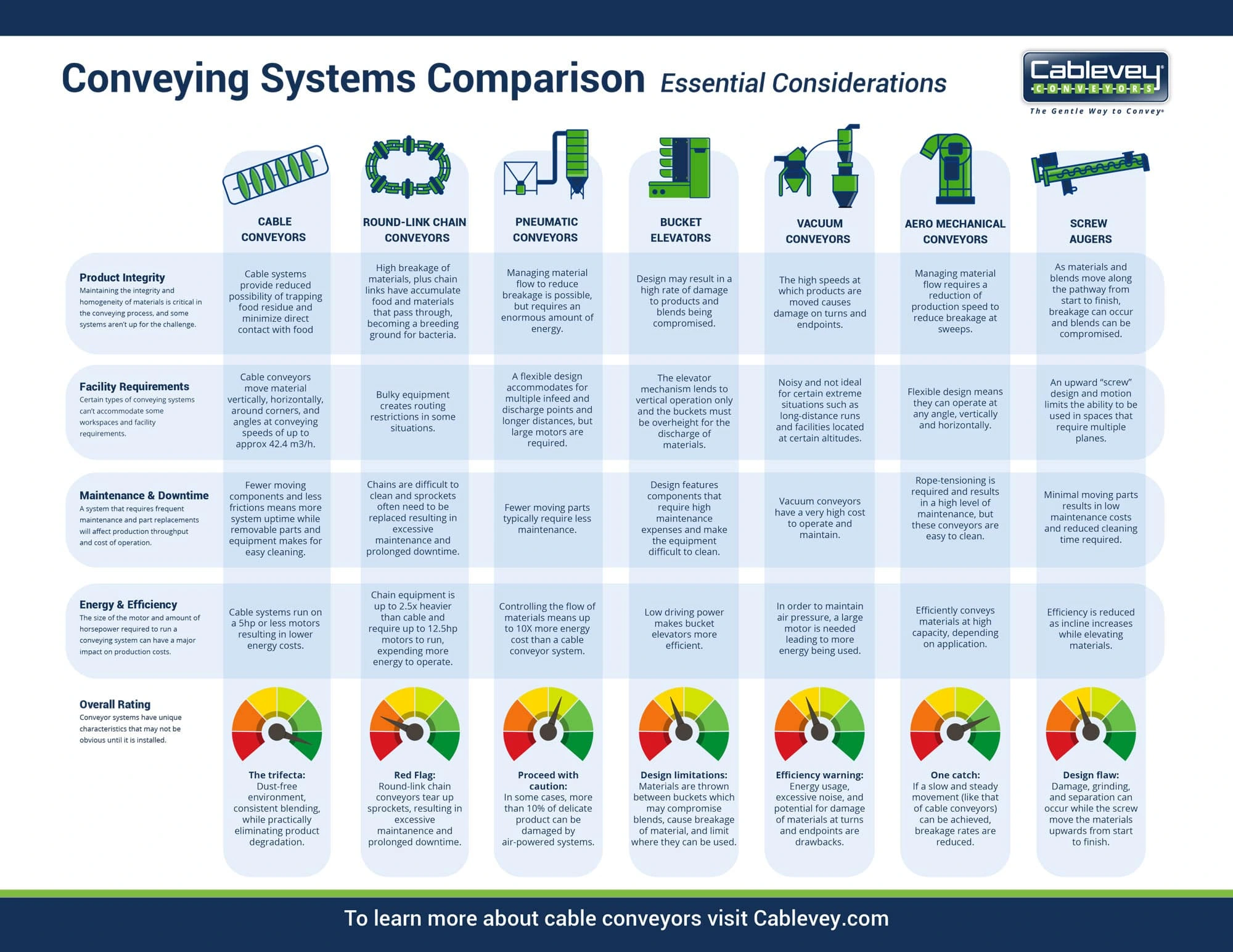

When it comes to moving materials around, the right automated conveyor system can make all the difference. Comparing Cablevey Conveyors vs. other conveyors can show you all about their design, how they work, and why they might be the better option for your needs. Whether you’re moving coffee beans, nuts, or even delicate electronics, understanding the differences can help you make a smart decision.

Cablevey Conveyors vs. Other Conveyor Systems – Picking the Best for Your Business

When it comes to different conveyor belt systems, options range from traditional conveyor belts to advanced automated conveyor systems. Among these, Cablevey Conveyors manufactures a premier tubular conveying system, offering a unique blend of efficiency and gentle handling. But before you make up your mind, we’ll compare the sophisticated engineering of Cablevey’s tubular conveyor technology with other conveyor belt systems, including belt conveyor systems renowned for their robustness in various industries.

Belt conveyor manufacturers innovate to offer more automated conveyor systems and tailored conveyor solutions. They do so by understanding the nuances of each system, from conveyor installation to cleaning conveyor belts.

How Cablevey Conveyors Reduce Energy Consumption

When it comes to energy use, Cablevey sets itself apart with its highly efficient conveyance systems. The accompanying chart showcases how our standard 5HP motor stacks up against other methods. For instance, chain conveyors typically consume 2.5 times more energy. Even more striking is the comparison with pneumatic conveyors, which can use up to an astonishing 10 times more power.

Horsepower/ Kilowatts

1

5.4

7.5

12

25

50

Full Load AMP

1.6

7.2

9.5

16

31.7

63.4

NEMA Efficiency

85.50%

89.50%

91.70%

91.70%

91.70%

91.70%

Annual Cost*

$419

$2,160

$2,928

$4,684

$9,758

$19,517

2000 Series – Maximum 75 Ft³/hour (2.12 M³) 2”-50mm

Cable Speed

Flow Rate

Ft/Minute

40

60

80

100

Meter/Minute

12.19

18.29

24.38

30.48

Ft³/Hour

30

45

60

75

Lbs./Hour*

1,200

1,800

2,400

3,000

m³/Hour

0.85

1.27

1.7

2.12

Kg./Hour

544

816

1,088

1,361

2000 Series – Maximum 75 Ft³/hour (2.12 M³) 2”-50mm

Cable Speed

Ft/Minute

40

60

80

100

Meter/Minute

12.19

18.29

24.38

30.48

Flow Rate

Ft³/Hour

30

45

60

75

Lbs./Hour*

1,200

1,800

2,400

3,000

m³/Hour

0.85

1.27

1.7

2.12

Kg./Hour

544

816

1,088

1,361

4000 Series – Maximum 525 Ft³/Hour (14.87 M³) 4”-100mm

Cable Speed

Flow Rate

Ft/Minute

40

60

80

100

120

140

Meter/Minute

12.19

18.29

24.38

30.48

36.57

43

Ft³/Hour

150

225

300

375

450

525

Lbs./Hour*

6,000

9,000

12,000

15,000

18,000

21,000

m³/Hour

4.25

6.37

8.5

10.62

12.74

14.87

Kg./Hour

2,722

4,082

5,442

6,803

8,163

9,524

4000 Series – Maximum 525 Ft³/Hour (14.87 M³) 4”-100mm

Cable Speed

Ft/Minute

40

60

80

100

120

140

Meter/Minute

12.19

18.29

24.38

30.48

36.57

43

Flow Rate

Ft³/Hour

150

225

300

375

450

525

Lbs./Hour*

6,000

9,000

12,000

15,000

18,000

21,000

m³/Hour

4.25

6.37

8.5

10.62

12.74

14.87

Kg./Hour

2,722

4,082

5,442

6,803

8,163

9,524

6000 Series – Maximum 1,240 Ft³/Hour (35.4 M³) 6”-100mm

Cable Speed

Flow Rate

Ft/Minute

40

60

80

100

120

140

Meter/Minute

12

18

24

30

36

43

Ft³/Hour

350

530

710

880

1,060

1,240

Lbs./Hour*

14,120

21,180

28,240

35,300

42,360

49,420

m³/Hour

10

15

20

25

30

35

Kg./Hour

6,400

9,610

12,810

16,010

19,210

22,420

6000 Series – Maximum 1,240 Ft³/Hour (35.4 M³) 6”-100mm

Cable Speed

Ft/Minute

40

60

80

100

120

140

Meter/Minute

12

18

24

30

36

43

Flow Rate

Ft³/Hour

350

530

710

880

1,060

1,240

Lbs./Hour*

14,120

21,180

28,240

35,300

42,360

49,420

m³/Hour

10

15

20

25

30

35

Kg./Hour

6,400

9,610

12,810

16,010

19,210

22,420

8000 Series – Maximum 2,000 Ft³/Hour (56.6 M³) 8”-203.2mm

Cable Speed

Flow Rate

Ft/Minute

40

60

80

100

120

140

Meter/Minute

12

18

24

30

36

43

Ft³/Hour

571

857

1,143

1,429

1,714

2000

Lbs./Hour*

22,840

34,280

45,720

57,160

68,560

80,000

m³/Hour

16

24

32

40

48

54

Kg./Hour

10,360

15,549

20,738

25,927

31,098

36,287

8000 Series – Maximum 2,000 Ft³/Hour (56.6 M³) 8”-203.2mm

Cable Speed

Ft/Minute

40

60

80

100

120

140

Meter/Minute

12

18

24

30

36

43

Flow Rate

Ft³/Hour

571

857

1,143

1,429

1,714

2000

Lbs./Hour*

22,840

34,280

45,720

57,160

68,560

80,000

m³/Hour

16

24

32

40

48

54

Kg./Hour

10,360

15,549

20,738

25,927

31,098

36,287

Cablevey Conveyors vs. Auger Conveyors

Cablevey conveyors share some common ground with auger conveyors, such as lowering noise levels and securing materials within an enclosed space for safe transport. Moreover, our conveyors offer added versatility in installation, handle materials with care to maintain integrity, and are designed for hassle-free cleaning.

Cablevey Conveyors vs. Pneumatic Conveyors

Similar to pneumatic systems, Cablevey conveyors protect materials within an enclosed environment. Beyond just the enclosed tubing, our systems excel with their gentle approach to material handling, energy-efficient operation, adaptable installation configurations, and versatile cleaning options suitable for both wet and dry conditions.

Cablevey Conveyors vs. Bucket Conveyors

Cablevey conveyors share the benefits of low noise operation and energy efficiency with bucket elevator systems while also minimizing material degradation akin to tube conveyors. What sets Cablevey conveyors apart is the enclosed tubing, which safeguards materials against spillage and contamination, the adaptability of conveyor layouts to various spaces, and the ease of sanitization and cleaning.

Cablevey Conveyors vs. Chain Disc Conveyors

Chain disc conveyors and Cablevey conveyors both provide the advantage of enclosing materials for protection and offer versatile layout and installation possibilities. However, Cablevey conveyors stand out due to their gentle handling of materials, substantial energy savings, and the straightforward cleaning process for all internal parts.

FAQ

How Do Cablevey Conveyors Differ From Traditional Conveyor Systems?

Cablevey Conveyors are designed to be more energy-efficient, cause less material degradation, and provide an enclosed system that protects materials from contamination. They stand out for their gentle handling of materials and ease of cleaning.

Can Cablevey Conveyors Handle Different Types of Materials?

Yes, Cablevey Conveyors can transport a variety of materials, from grains and powders to pellets and even delicate products, without causing damage due to their gentle conveying process.

Are Cablevey Conveyors Suitable for Different Facility Layouts?

Absolutely. Cablevey Conveyors are known for their flexibility in layout and installation, making them suitable for a variety of facility designs and spaces.

How Do Cablevey Conveyors Compare to Pneumatic Systems in Terms of Energy Use?

Cablevey Conveyors are significantly more energy-efficient than pneumatic systems, which can use up to 10 times more power to operate.

What Makes Cablevey Conveyors a Cleaner Option?

The enclosed design of Cablevey Conveyors not only protects the materials but also contains any dust or spillage, making it a cleaner option. Additionally, they are designed for easy cleaning, with both wet and dry options available to suit different materials.

Contact us for more product updates