In the fast-paced world of industrial processing and manufacturing, efficiency and precision are paramount. Nut conveyor systems play a crucial role in achieving these goals. From their underlying principles to their wide-ranging applications, get ready to dive deep into the intricate workings and transformative potential of nut conveyor systems.

What Are Nut Conveyor Systems and Why Are They Important?

A nut conveyor system is a specialized piece of industrial equipment designed to transport and handle nuts in bulk quantities. This system is typically used in various sectors like agriculture, food processing, and manufacturing, where large amounts of nuts need to be moved efficiently and reliably. The importance of a nut conveyor system lies in its ability to significantly enhance productivity, minimize manual labor, and reduce the risk of product damage.

By enabling a continuous, controlled, and automated flow of nuts, these systems ensure that the products reach their destination in optimal condition, thus maintaining quality and boosting overall operational efficiency. The nut conveyor system, therefore, is a cornerstone of many industrial processes, promoting safety, precision, and cost-effectiveness.

The Global Nuts and Seeds Industry Trends

According to statistics, the global nuts and seeds industry is valued at $1,301.4 billion. Between 2020 and 2021, more than 5.3 million metric tons of tree nuts were produced. The top 5 tree nuts are almonds, walnuts, cashews, pistachios, and hazelnuts. Pecans, pine nuts, macadamia nuts, and peanuts are also popular.

Every year, nut processing companies are looking for ways to increase their efficiency and throughput. One way to do this is by installing the right conveying system. The top three benefits of having a conveyor system specifically designed for conveying nuts are:

- Increased efficiency,

- Reduced costs,

- Improved safety.

This comprehensive guide to nut conveyor systems will teach you everything you need to know about the different types of systems, the most common challenges faced when conveying nuts, and how to choose the right system for your needs.

Nuts as a Conveyed Material

Before we dive into the world of nut conveyor systems, it’s important to understand a little bit about the material being conveyed – nuts! Nuts are classified as dry, flowable solids. (Flowable means that they can move through a conveyor system without the need for flow promotion devices.) They come in all shapes and sizes, from tiny pine nuts to large Brazil nuts. However, there are some crucial factors regarding nuts you need to consider when choosing a conveyor system.

Without exception, all nuts are used for consumption, whether by humans or animals. They can be used in their whole form or as an ingredient in a recipe. The most common use for nuts is as a snack food, where they are often roasted, flavored, or salted. Because nuts are used in the food industry, the bulk material handling equipment that comes in direct contact with them must be made of food-grade materials.

All contact parts of the food conveyor system, such as belts, chains, cables, tubes, and similar, should be FDA/USDA approved for direct food contact. Food safety standards need to be followed to protect both the consumer and the manufacturer. An additional layer of safety is added by following certain non-regulatory standards, such as the 3-A sanitary standards, that are specific to the food industry.

Are you conveying only one type of nut? Or do you need to convey a variety of different nuts? The answer to this question will have an impact on the type of conveyor system you need. As mentioned above, nuts come in all shapes and sizes, from large to tiny. Some are round, while others are oval or irregularly shaped. If you need to convey only one type of nut, then you have more flexibility in your choice of a conveyor.

But if you need to convey a variety of different nuts, then you will need to choose a system that can handle a range of sizes and shapes. Similarly, you need to consider whether you want to transport whole nuts or nut pieces. Sliced, chopped, and even ground nuts might require different conveying equipment than whole nuts.

Bulk density represents the weight of a given volume of bulk material. For example, the average bulk density of almond kernels (the part of almonds that we eat) is 33 lb/ft3. This means that if you have one cubic foot of space, it will contain 33 pounds of almonds. The bulk density of a material is important to consider when choosing a conveyor system because it affects the capacity of the system. Bulk densities of different types of tree nuts can vary between 30 to 40 lb/ft3. The conveyor system provider should be able to help you calculate the capacity of the system you need based on the bulk density of your material.

Challenges of Conveying Nuts

Now that we are familiar with the basic characteristics of nuts, let’s look at some of the problems associated with conveying them. What are the challenges of nut conveying?

Material Damage and Loss

Anyone who has ever tried to eat a handful of nuts knows that they are hard and have a tendency to break. This same hardness can cause problems when conveying nuts, as they are susceptible to damage from abrasion and impact. Abrasion occurs when two surfaces rub together, causing wear and tear on both surfaces. Impact happens when an object hits another object, resulting in damage to one or both of them.

No less than 30% of food processing businesses name broken materials as one of their top three challenges of conveying. As a fragile material, nuts require special care when being conveyed to avoid damage. Conveyor systems such as the belt conveyor system or the chain conveyor can cause abrasion as the nuts come into contact with their moving parts. Systems that use gravity to move the nuts (such as chutes or vibrating conveyors) are more likely to cause impact damage, as the nuts will hit the sides of the chute or conveyor as they move.

Material damage leads to a drastic decrease in the quality of the final product. Additionally, the little bits and pieces that break off the nuts can get caught in the conveyor system and cause jams. Material waste is also a concern, as even a small amount of damage can result in a significant amount of lost product even if reclaimed as a lesser-value material.

Contamination and Cross-Contamination

In the intricate process of conveying nuts, one key challenge is contamination prevention. This is crucial as it ensures the safety and quality of the final product. Understanding contamination involves recognizing two types:

- Primary contamination occurs when food interacts directly with a source that can introduce harmful organisms such as bacteria or viruses. Primary contamination can happen at any stage of the food’s life cycle, from its initial production and processing, right through to packaging.

- Cross-contamination is the transfer of organisms from one food item to another. In the food industry, this form of contamination is especially concerning, as it can cause severe illness or, in extreme cases, death.

There are a few ways that contamination can happen when conveying nuts, and it’s shown in the table below.

| Source of Contamination | Description |

| Unclean conveyor system | An improperly cleaned conveyor system poses the risk of bacteria being transferred from one batch of nuts to another. |

| Poorly designed system | If the conveyor system isn’t optimally designed, outside environmental factors like dust or pests can introduce contamination. |

| Oil residue from nuts | Nuts, due to their high oil content, often leave behind oil residues on surfaces they touch. This residue can become a breeding ground for bacteria, potentially contaminating other food items in contact with the same surface. |

Created Dust

Dust is always a concern regardless of what form nuts are in during transport (but especially if you are moving ground nuts). When nuts are moved, they inevitably create dust. This dust can contain small particles of the nut itself, as well as bacteria and other contaminants. If not properly controlled, the dust can contaminate the product and cause respiratory problems for those who come into contact with it.

Additionally, the dust can clog up the conveyor system and cause jams. It can also coat the nuts, making them difficult to handle and increasing the risk of contamination. Dust explosions are another serious concern. When a dust particle comes into contact with an ignition source (like a spark), it can cause a small explosion. These explosions can damage equipment, injure people, and even start fires.

Choosing the Right Nut Conveyor

To mitigate all of the conveying issues discussed above, it is important to choose the right nut conveyor system for your needs. When selecting a conveyor, there are a few key factors to consider, such as throughput, layout and design level of automation, and the planned budget.

Consider the Throughput

Throughput is the rate at which the conveyor can move the product. This is typically measured in tons or pounds per hour (or per minute, in some cases). It is important to choose a system that has enough capacity to meet your needs. If you are conveying large quantities of nuts, you will need a conveyor with high throughput.

Layout and Design

When considering your conveyor options, you cannot lose sight of the amount of available floor space you have. The layout of your facility will have a big impact on the type of conveyor you can use. If space is limited, you may need to choose a compact conveyor system. Additionally, the design of the conveyor system is important. Do you need a horizontal or vertical conveyor? Are there any areas where the product needs to be turned or sorted? Do you have mezzanines or other obstacles that need to be taken into account?

Make sure to consider how the system will be cleaned and maintained. Easy cleaning and maintenance will go a long way in reducing your downtime. You will also want to think about how the system will be integrated into your existing production line.

Level of Automation

Automated conveying systems come with a wide range of advantages, including increased efficiency and accuracy, lower labor costs, and reduced risk of injury. However, they also come with a higher price tag. When deciding on the automation conveyor systems you need, you must consider your budget and your production needs. An automated system may be a good investment if you are conveying large quantities of nuts. If you are only conveying small amounts, a manual system may be sufficient.

Budget Size

A new conveyor is an incredibly capital-intensive investment. When considering your budget, you must think about the long-term costs of ownership, including energy expenditure, maintenance, repairs, and replacement parts. You will also want to factor in the cost of installation and integration into your existing conveyor line. If you are replacing a current conveyor system, you may be able to reuse some of the existing infrastructure, which can save you some money.

Which Conveyor Is Best for Moving Nuts?

If you went googling for “nut conveyor” or “conveyor for nuts,” you would find that most of the results include several of the same systems:

- Pneumatic conveyor,

- Conveyor belt system,

- Screw conveyor (auger conveyor)

- Vibrating conveyor,

- Bucket conveyor.

Out of all of these, pneumatic conveyors are the most commonly used for conveying nuts. Even though they have some benefits in conveying, they are not the best option for materials as fragile as nuts.

How Pneumatic Conveyors Work

Pneumatic systems use air pressure to move the material. The air pressure is generated by a blower or compressor and is sent through a system of hoses and tubes. The material is fed into the system at one end and is conveyed through the tubes by the airflow. According to the type of air pressure used (positive or negative), pneumatic conveyors can be classified as:

- Vacuum conveyors – the material is conveyed through a system of tubes using negative air pressure.

- Pressure conveyors – the material is conveyed through a system of tubes using positive air pressure.

And according to the velocity of the airflow, pneumatic conveyors can be classified as dilute phase conveyors and dense phase conveyors. The dilute phase conveyor operates by suspending the material in the airflow and conveying it at high velocity, typically over 59 feet per second. This method allows for rapid transportation, making it an efficient choice for certain applications.

On the other hand, the dense phase conveyor transports material at a slower velocity, ranging from 20 to 59 feet per second. In this system, the material stays in contact with the walls of the tubes during transportation. This technique, while slower, can often provide a gentler conveyance, which might be preferable depending on the nature of the material being transported. In theory, dense-phase pneumatic conveyor systems would be a good fit for conveying nuts. However, in practice, the situation is quite different.

Downsides of Pneumatic Conveyors

While pneumatic conveyors can be highly effective for many industrial applications, they may not be the optimal choice when it comes to conveying nuts. There are two significant reasons for this assertion: their potentially destructive impact on the materials and their high energy consumption.

Because of the incredibly high speeds developed in a pneumatic system, the particles of the conveyed material are subject to a lot of wear and tear – the abrasion and impact damage we mentioned earlier. This is especially true for fragile materials like nuts. Damaged raw materials can lead to increased rejects and decreased product quality. Customers are not likely to be happy with a product that is full of damaged or broken nuts, which would most likely result in a loss of business. Since keeping the integrity of your raw materials is imperative in the nut processing industry, pneumatic conveyors are not a good option.

In addition to being destructive to the material, pneumatic conveyors are also very energy-intensive. The high air pressure required to move the material through the system uses a lot of power, which can drive up your energy costs. This is especially true if you wish to decrease the conveying velocity in order to prevent damage to the nuts. A lower conveying speed will require even more air pressure to maintain the same material flow rate, which will result in even higher energy consumption. If you are a business working to decrease its carbon footprint or lower its energy costs, pneumatic conveyors are not the right choice.

What type of conveyor should you use, then?

Tubular Drag Conveyors – The Ideal Solution

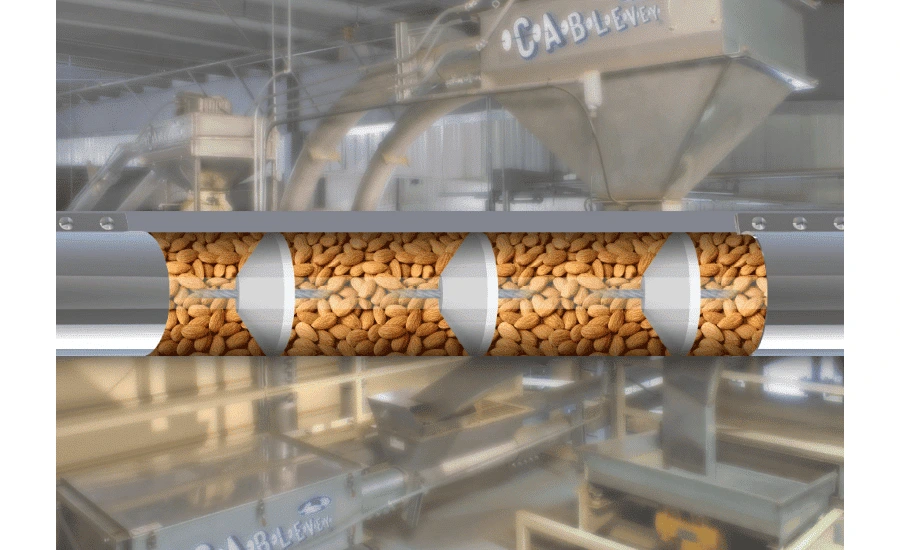

Instead of a pneumatic or similarly material-destructive system, you should opt for a tubular drag conveyor. Tubular drag conveyors (also called tube cable and disc conveyors) are mechanically driven systems that use a cable and disc assembly to move materials through a series of tubes.

The main conveying path is a tube through which a sealed cable runs through. Evenly spaced along this cable are solid circular discs that are connected to the cable. They create “pockets” where the material to be conveyed can sit. When the system is turned on, the discs move along the tube, pushing the material with them. The material then moves through the conveying system until it reaches its destination.

Tubular Drag Conveyor Advantages

The first and most important benefit of tubular drag conveyors is that they are gentle on the material. The discs move slowly and create a pocketed conveying path, which protects fragile items like nuts from abrasion, impact damage, and degradation. You won’t find a more gentle way to move your product.

Another big advantage is that, in contrast to pneumatic systems, tubular drag conveyors don’t require a lot of power to operate. In fact, some tubular drag systems can work even with a 5 HP drive unit! Aside from these two key advantages, tubular drag conveyors also offer several other benefits:

- They are enclosed, meaning that the chances of contamination or the release of dust and other airborne particles are very low. This is ideal for food-grade applications.

- They have a modular design, meaning they can be easily customized to your specific needs, regardless of whether you need a vertical or horizontal custom conveyor belt for food (or both).

- They have a small footprint and can be installed in almost any type of facility.

- They require very little maintenance and are very easy to clean.

- They are suitable for conveying a wide variety of materials, not just nuts.

This is just a short list of all the advantages that tubular drag conveyors offer. If you are looking for a safe, gentle, and low-maintenance way to move your nuts, this is the ideal solution.

Choosing the Right Conveying System – The Superiority of Tubular Drag Conveyors for Nut Handling

Nut conveying is not an easy task, but it is a crucial process in the nut industry. Nuts are fragile and easily damaged, so you need to be careful when choosing a conveying system. They also need to be protected from contamination – and your facility needs to be protected from dust – which is why enclosed systems are the best option.

Pneumatic conveyor systems are often used for conveying nuts, but they have several disadvantages that make them unsuitable for conveying such delicate materials. Tubular drag conveyors are a much better solution. They are gentle on the material, low-maintenance, easy to clean, and have a small footprint.If you’re in need of an industrial conveyor belt for a warehouse or your manufacturing processes, and you’d like to learn more about tubular drag conveyors and how they can be used for conveying nuts, contact Cablevey Conveyors today. Our experts will be happy to help you choose the right system for your needs.