Discover the art of conveying with finesse in our insightful guide on how to convey tea. Whether you’re a tea enthusiast or a business owner in the processing industry, learning about the techniques and tools for tea conveyance is of utmost importance. In the following text, we’ll delve into the intricacies of this process.

A first-hand account of how cable conveyors are changing the nature of tea processing by Karl Seidel, a coffee roaster and marketing manager for Cablevey Conveyors.

Cable Conveyors for Tea – A Drag That’s Not a Drag

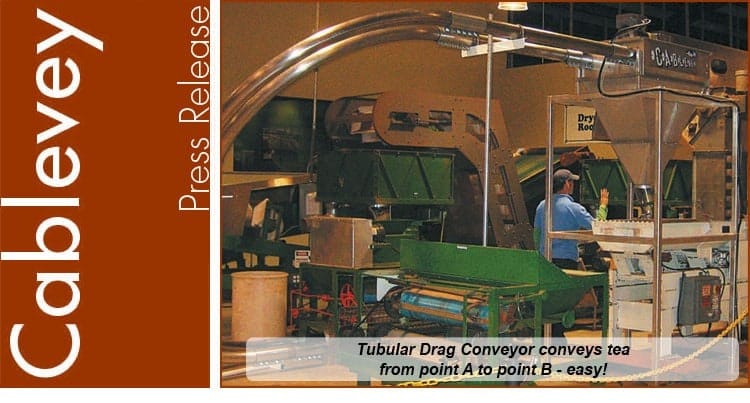

Not long ago, I toured the production facility of a major tea operation that uses tubular drag cable conveyors. It is very interesting to observe brews whizzing by in story-high, modern configurations and get a close look at beautiful leaf products. It also lends a fun “aha!” experience into how these conveyor systems are set up once off the engineer’s blueprint, elegantly transporting an impressive quantity of fine product from point A to point B.

There is often a very large volume of tea being conveyed inside such state-of-the-art facilities. The tea processor has let me pick their brain that day and tour the facility. Still, it is not unusual for them to remain anonymous to outsiders.

As a coffee roaster with a keen interest in products like brews, nuts, spices, and coffee beans, I stood transfixed as an enormous amount of splendid black tea moved quickly through tubes inside the plant. It’s typical to know that some aspect of food processing can be done, but it is so much better to see and grasp how it’s done.

Tea Processing – An Efficient Process Thanks to Quality Conveyor Solutions

I saw a great deal of efficiency and an amazing layout of tubes, turnarounds, discharge points, and a lot of product. It was fun. To visualize the entire process, you might draw on your own experience, take a facility tour like I did, or jump on the internet. If you go to YouTube and enter the search words “tea processing,” you can watch videos showing just how tea is processed in all kinds of facilities.

Tea Processing – What Is the Process Like?

It’s certainly important to keep the integrity of the product while conveying and to protect it from contamination. There are many steps along the way, whether using tubular conveyor systems or not. The materials can be picked, sorted, bruised, panned, steamed, cleaned, fired, dried, rolled, fermented, withered, scattered, boxed, and steeped – or any of these dizzying combinations.

You will see many of those steps in a good production facility or in a demonstration video and also hear debates about the right time to stop wilting and oxidation. You can also watch leaves roll, fall, lift, or cascade between mesh air dryers that are three stories high.

Stages of Processing

Most brews usually go through several generic stages that include wilting, bruising, oxidation, kill green, shaping, and drying. Green tea is a bit different, and the first three steps are usually skipped. Yellow tea is additionally yellowed, and oolong is mostly cured after drying, as are some of the post-fermented teas.

And then, within each category, there are sub-processes. For example, “kill green,” a process to stop oxidation, is typically done by baking white tea, by panning oolong (or baking), and by steaming green tea (though sometimes by panning – there is industry variance). There are production variations and improvements. Indeed, there are many aspects and approaches in processing, possibly as many as there are places where raw materials grow (although mostly throughout China, India, and Japan).

What Conveyor Technologies Are Used for Tea Processing?

With many production facilities, huge amounts of tea are no longer being conveyed with buckets, belts, or chains. Nowadays, conveying is done much more carefully – through tubes where the product is dragged internally and safely to its next destination. These systems are highly efficient.

Carl Teten of S&D Coffee in Concord, North Carolina, says, “We have four main tubular drag conveyors right now, each running over five million lbs. of black tea annually with no downtime.” Conveyor solutions can be made to fit any of the generic processing stages, although most producers use tubular drag conveyors after the last drying stage when the product is at its most fragile, valuable pre-packaging point.

How Do Tubular Drag Cable Conveyors Work?

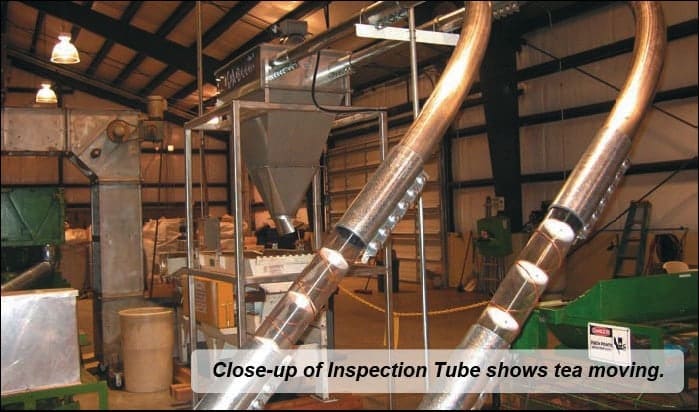

It’s helpful to look at how these tubes actually work when conveying the material. The tea travels along inside covered or see-through tubes because discs pulled by cables inside the tubes “drag” the quantities of the product along. It’s very safe, clever and efficient. Imagine an enclosed horizontal tube with flexible vertical discs carrying the tea along in the proper direction (although the tubes in real life travel in any direction).

Benefits of Using Tubular Conveyor Systems

Materials move through the conveyor but in varying configurations depending on the needs of the client. Also, clients are not stuck with one configuration or trying to make the new conveyor solutions fit their existing space. You don’t need to worry about the existing equipment being moved all about in inconvenient ways since all systems are designed for them. Think of the flexibility of Lego building blocks but astronomically more sophisticated.

In this kind of system, there are various points for inspection, discharge points, spots to view the product passing through, and often a turnaround unit that can be opened. One company recently found that it makes sense to put a handy see-through panel on the turnaround as well. With a configured tubular conveying system, the client can use existing production space and integrate the cost-saving conveyor with existing equipment.

Production flow can be adjusted with various available speeds. The best systems have a separate clean-out disc made of urethane, and as it moves through the tubes, it wipes the tube clean. The clean-out disc is different from the “regular” discs that do the actual conveying. That disc is a bit larger in diameter than the tubes, specifically for that self-cleaning purpose.

Why Are These Conveyor Technologies Better Than Traditional Conveyors?

Producers find several advantages to using tubular drag conveyors over older methodology. First, these systems are commercially available to small, medium, large, or humongous operations. Next, these tubes carry the product from point A to point B without using air blasts, vacuums, conveyor belts, or buckets, so it is a very gentle process.

Designs offered include many options in layout, length, and size, such as two, four, or six-inch diameter. Essentially, any design configuration that is needed can be accommodated. Also, there are no residual flavors if the tea type changes because the systems are self-cleaning and use the urethane disc in the form of a squeegee.

Testing the Conveyor Engineering for Tea Processing Purposes

Some clients travel directly to the manufacturing location to run their products through the tubes and test their leaves in those systems. But in most cases, that isn’t necessary since the tea is routinely sent and tested ahead of time.

The results are not only tracked with care and discussed with the producer but sometimes videotaped, uploaded to a private website, and transmitted back along with an analysis for the clients to consider. Also, if the producer wants to add more systems, larger capacity systems, or transfer systems around, that can be done as the processor grows.

What to Expect From the Conveyor Installation Process?

Ease of conveyor installation routinely surprises tubular drag conveyor clients, but the measurements and plans, as with any well-made equipment, are carefully made in advance. There is also the option of conveyor installation supervision. Existing personnel at the production facility can install the system or hook it up with hands-on help from the conveyor systems manufacturers.

“We especially like the ease of installation, which is important to us because it is expensive to have service personnel come into Canada, and we didn’t want to have to depend on other companies doing the installation,” said Jean-François Vallee, an engineer at Van Houtte in Montreal, speaking of tubular drag conveyors designed by Cablevey Conveyors. They are a manufacturer of food-protecting technology, dragging dry loose tea in enclosed tubes, expanding into this area from coffee about three years ago.

The process starts when an interested company or producer contacts the conveyor systems manufacturers for information and a quote. Engineers walk the client through various steps to determine the size, configuration, price, and the best set-up for their particular operation. After the quote is accepted, the company goes ahead with preparation, manufacturing, and delivery. Turnaround time is fast, and with a top company like Cablevey Conveyors, there is typically a six to eight-week wait for an order.

Others have had similar positive reactions about all points in the process, including as early as testing their particular tea through. When I spoke to Carl Teten right after testing, he told me, “I have five additional Cablevey systems that I’m getting ready to install for moving tea from a 10,000-lbs. silo using multiple discharge points. The tests ran beautifully. Once we put the system in, we were done.”

Cablevey Conveyors – Moving Boundaries With Cutting-Edge Conveyor Technologies

Phil Hall, president of Cablevey Conveyors, says, “Our goal is to get tea producers to love this technology and give us their feedback because it reflects on the market opportunity, and it only proves even more the satisfaction we are already seeing for tubular systems as a great conveyor of tea.”

Yogi Berra once said, referring to distance, “It’s not too far, it just seems like it is.” Maybe with these modern conveyors, the distance of moving tea will feel much less. Cablevey Conveyors has cutting-edge but proven technology for efficient conveyance. Tubular drag conveyor systems already serve many sectors of food, agriculture, and industry, but to see their efficient application with tea and coffee is very exciting.

Contact us at Cablevey Conveyors if you want to learn more about our outstanding conveyor systems or get a quote!

FAQ

What Types of Conveyor Technologies Are Used for Tea Processing?

Tea processing commonly employs tubular drag cable conveyors. These conveyors offer a gentle and efficient method of moving tea from one point to another without using air blasts, vacuums, conveyor belts, or buckets. They are particularly effective in maintaining the quality of the product.

How Do Tubular Drag Cable Conveyors Work for Tea Processing?

Tubular drag cable conveyors function by using enclosed tubes with flexible vertical discs pulled by cables. These discs effectively drag quantities of tea along the tubes, ensuring the product is transported safely and efficiently. This design is clever and efficient, offering a gentle way to handle tea during the conveyance process.

Why Are Tubular Drag Cable Conveyors Considered Better Than Traditional Conveyors for Tea Processing?

They are commercially available for operations of all sizes, from small to large. These conveyors move tea gently and without the need for air blasts or other forceful methods. They are highly customizable in terms of layout, length, and size. They are self-cleaning, eliminating any concerns about residual flavors when changing tea types.