In a world where culinary delights span continents and cultures, the magic behind our vast array of edible offerings often goes unnoticed. At the heart of this gastronomic revolution lies the intricate dance of food processing and processed foods. Picture a grand conveyor belt system, tirelessly working behind the scenes, carrying the secrets of flavors, textures, and innovations. Well, we’re here to help you dig even deeper into this topic, so keep reading.

In the past several decades, there have been numerous technological advancements made in the food processing industry. Coupled with the increase in demand, the industry is expected to grow even further. In this ultimate guide, we will be taking a closer look at processed food and the technology used to produce and handle it.

Food Processing and Processed Foods Industry

With the increase in urbanization and middle-class income growth, processed food consumption has increased. Therefore, the market for processed foods has been consistently expanding. Forecasts indicate an increase from $53.2 billion in 2019 to $64.7 billion by 2024, with an annual growth rate of 4.0%.

When it comes to the global food processing and handling equipment market, the figures are even higher. In 2019, the processed food industry was valued at around $137.2 billion and is expected to reach $196.6 billion by 2025 at a CAGR of 6.2%.

What Are Processed Foods?

In its most encompassing definition, processed food is pretty much everything that needs to undergo some process before being consumed. In other words, everything from bread, cheese, breakfast cereals, canned foods, frozen fruits and vegetables, peanut butter, dried fruits, cold cuts, frozen meals, and everything else in between can be classified as processed food.

Even though processed foods are commonly associated with obesity, heart disease, diabetes, or other health issues, the reality is somewhat different. In many cases, in fact, food processing will increase the food’s safety. Milk, for instance, needs to be pasteurized (a heat processing treatment) to remove any harmful bacteria. Other foods will require some degree of processing before they can even become suitable for consumption.

How Food Processing Equipment Works?

Food processing equipment represents an umbrella term that covers numerous machines, components, and systems used to cook, handle, prepare, preserve, package, and store different types of processed foods. In the majority of cases, food processing equipment is used to increase the palatability and digestibility of foods as well as extend their shelf life.

The Double-Edged Sword of Processed Foods in the American Diet

Heavily-processed foods will often contain high levels of salt, sugar, and trans fats. These types of ultra-processed foods make up around 58% of all calories and 90% of all added sugars in the typical American diet.

That said, avoiding all processed foods is next to impossible, especially for those that don’t grow their own food. While many processed foods have various ingredients added to their composition, such as oils, sweeteners, coloring agents, and preservatives, many are also fortified with nutrients like dietary fiber, vitamins, and minerals.

Explore the Benefits of Processed Foods

There are numerous benefits to be had from processed foods. Among these, we can include increased preservation, toxin removal, better consistency, taste, and more. Also, it allows for the transportation of highly perishable foods over greater distances by deactivating enzymes or pathogenic microorganisms that will lead to spoilage. When they first became available, processed foods helped alleviate food shortages and improve the nutrition levels of people in different parts of the world.

The Unsung Benefits of Food Processing in Modern Cuisine

Processed foods also made it possible to reduce foodborne illnesses and dangerous pathogens that can sometimes be found in raw foods. Today’s food variety is also only possible thanks to food processing.

Transporting various exotic fruits, vegetables, and other foods is only possible due to the increased preservation methods during processing. It should also be mentioned that food processing has also greatly increased the taste of today’s food compared to what people used to eat in the past.

Breaking Down Food Processing

The primary purpose behind food processing has been to transform various agricultural products into edible food. One such example is turning otherwise inedible wheat grain into raw flour. More complex industrial food processing methods will also transform one type of food product into another, such as the case of raw meat into sausages or sunflower seeds into sunflower oil. Some processing methods will also play an essential role in boosting food preservation and reducing waste, increasing food security, and lowering agriculture’s overall impact on the environment.

Processed foods don’t only include snacks and high-processed meals like TV dinners. They include all different types of food that have undergone some form of change during their preparation. Even something as basic as freezing, baking, drying, smoking, salting, or canning can be included under the umbrella term of food processing. There are also different levels of processing, which range from minimally processed to heavily processed foods.

The Primary Stage

During the primary stage of processing, food manufacturers will turn various agricultural products, such as wheat or corn kernels, into ingredients that can be used for further processing, such as flour or maize. Numerous processes fall within this category, such as drying, shelling, milling, and threshing. Canning fruits and vegetables, deboning and cutting meat, candling eggs, and pasteurizing milk are also processes that fall in the initial stages of food processing.

The Secondary Stage

The secondary stage is about turning ready-to-use ingredients, typically developed during the first stage, into edible food. Cooking is a typical example that falls in this category. Bread baking, cheese or sausage making, beer brewing, or winemaking are also examples of second-stage processing.

The Third Stage of Food Processing

This stage includes ultra-processed foods containing additional ingredients such as coloring and preservative agents, additional salt, sugar, and fats, and even fortified with extra nutrients in dietary fiber, vitamins, and minerals.

The Food Processing Production Cycle

When considering the production cycle of food processing, the equipment used can be classified based on the specific functions and individual unit operations that they will perform. For example, during the preparation stage, one of the main functions is to prepare the materials for further processing. That said, the food processing production cycle can be broken down into the following stages:

The Preparation Stage

In the preparation phase, raw materials are readied for subsequent processing. Key steps involve separating quality ingredients from undesirables, ensuring consistent, high-quality food, and removing contaminants. Overlooking this can lead to foodborne illnesses. Techniques encompass cleaning, sorting, grading, and peeling, using equipment like screen separators, washers, tanks, ultrasonic cleaners, and magnetic separators.

The Mechanical Processing Stage

Mechanical processing alters the raw food’s physical form, enhancing subsequent processing efficiency and the end product’s quality. This versatility creates a broader array of food products. Key technologies in this stage are roll crushers, attrition mills, band saws, screw extruders, high-speed agitators, colloid mills, and emulsifiers.

The Heat Processing Stage

Heat treatments can modify food’s chemical structure, enhancing flavor and nutritional quality while eliminating pathogens and spoilage enzymes. Baking and roasting tools like ovens cater to flour-based products. Blanching uses steam or heated water to enhance food quality, while dehydration requires vacuum or freeze dryers.

The Pasteurization Stage

Pasteurization, using temperatures of 158-212°F (70-100°C), deactivates spoilage enzymes and harmful microbes, extending the shelf-life of foods without compromising quality. Commonly pasteurized items include beer, wine, and dairy. This can be achieved through continuous flow, in-container methods, or using plate and concentric tube heat exchangers.

The Preservation Stage

When heat isn’t sufficient for food preservation, alternative technologies step in. Chemical preservation, such as using salt, sugar, acids, or smoke, can prevent spoilage, albeit altering pH and nutrition. Ionizing radiation can neutralize enzymes and microbes, while refrigeration slows their activity.

Packaging And Material Handling

Packaging, an integral stage of food processing, comes in various forms like cans, bags, and jars, each requiring different technologies. Its main roles include containment, preservation, ease of handling, portioning, and facilitating transportation.

Different Types of Conveyor Systems Used in the Processed Food Industry

When it comes to the handling equipment used in the food processing industry, manufacturers have traditionally relied on a conveyor belt for food. This type of equipment is generally used to move food material through the food processing facility, from one station to the next, all the way from preparation to packaging.

As mentioned, there is more than just one custom conveyor belt system used in this industry. Among these, we can include the following:

- Bucket elevators – Put simply, a bucket elevator is a system that uses a continuous line of buckets to carry processed food product material in a vertical or horizontal direction. The most common of these bucket elevators are centrifugal and continuous. Also, centrifugal bucket elevators can cause product degradation as the systems shovel bulk materials in the elevator boot into the buckets.

- Augers – These are made out of a rotating screw powered by a rotating motor enclosed in a trough or shaft. The screw rotates whenever a food product is introduced into the system, moving it along a vertical, horizontal, or inclined plane from one end of the auger to the other. Depending on the application, the product falls into a container or rotary airlock.

- Pneumatic conveyor systems – Also known as air conveyors, pneumatic systems use pressurized air to move products from one area to another. These conveyors use air to move product through tubes and/or pipes by generating below atmospheric pressure. Among the many different pneumatic conveyors, the most basic is the dense phase and dilute phase conveyors. These systems differ in terms of pressure rates and speed.

- Vacuum conveyors – These systems are powered by vacuum pumps, which are driven by compressed air and can be controlled automatically. With this type of conveyor system, food material can be drawn through an enclosed pipeline in a contained air stream generated by the pump. However, the high speeds at which products are moved will cause damage at endpoints of sharp turns and discharge points.

- Aero-mechanical conveyors – These conveyor systems consist of a series of discs mounted at regular intervals on a cable enclosed in a tube. A motor thrusts the discs through the tube at high speeds, creating a current of moving air that moves the product. This type of conveyor system generates no dust and contaminants, as well as minimal product degradation.

Tubular Drag Cable Disc Conveyors Are the Best Bulk Material Handling Equipment

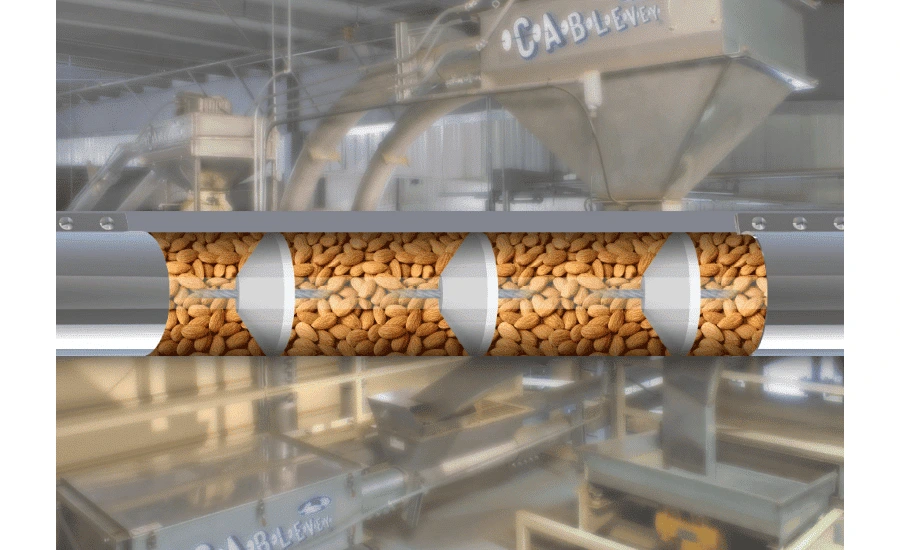

These systems gently move food material through a sealed tube with a drag chain or cable that’s pulled through it in a loop. Unlike a traditional conveyor belt for a warehouse, there are two types of this system on the market: the tubular drag chain conveyor and the tubular drag cable conveyor.

Chain conveyors will gently move bulk solid material via a sealed tube with a drag chain in a loop pulled through the tube. Food products are continuously moved through the system without any particle degradation.

Experience Efficient and Energy-Saving Material Movement With Tubular Drag Cable Conveyors

Tubular drag cable conveyors work the same as tubular drag chain conveyors, except that they use a cable-and-disc assembly to convey material. In a cable and disc conveyor, materials move through the tube at higher speeds than through a tubular drag chain conveyor.

Compared to the other conveyor systems, like a belt conveyor system, used in the processed food industry, tubular drag cable conveyors also use less energy to move material (7.5HP or fewer motors), while the low velocity of the tubular drag system reduces the wear and tear of the system’s components.

A disc and cable conveyor system is self-cleaning, thanks to the wipers that continually clean the tube. There is also a clean-in-place (CIP) system that enables simple equipment cleaning. These systems provide a reduced possibility of trapping food material residue and minimize direct contact. Cable conveyors can also move material horizontally, vertically, around corners, and at angles, making them particularly useful in tight spaces.

Maximizing Efficiency and Food Safety in Conveyance With Cablevey’s Conveyor Systems

Put simply, Cablevey Conveyors’ solutions have the capacity to transport as much as 2,000 cubic feet of material every hour within a sealed tube without relying on air. Offered in multiple configurations, these systems bolster food safety by preventing issues like product mixing, deterioration, or contamination. If you wish to upgrade your production line with state-of-the-art technology, you can find out all about these systems by contacting Cablevey Conveyors.