In the dynamic landscape of food processing, the reliance on advanced conveyor technologies is a must for safety and efficiency. But which conveyors are the most sanitary for food processing? This comprehensive guide delves into key factors such as clean-in-place technology, conveyor design, and construction, shedding light on the most optimal solutions for maintaining hygiene and safety in the food production line.

Which Conveyors Are the Most Sanitary for Food Processing?

Enclosed tubular conveyors, particularly Cablevey’s innovative tubular drag cable conveyors, stand out as the most sanitary choice for food processing. With a design that minimizes contamination risks, clean-in-place technology, and stainless steel connectors, these conveyors ensure optimal hygiene, making them the top pick for maintaining food safety standards.

Food plants all over the world depend on conveyor solutions for transporting materials. Manual material transportation is no longer an option for most of the food industry, and these systems must be safe and clean. If you’re looking for food-grade conveying that will keep your production line safe from bacteria like Listeria, check out all the features an automated conveyor system should have.

Enclosed Systems Provide a Superior Sanitation

First and foremost, an enclosed system, like the tubular conveyor, is the most sanitary conveyor option for food processors. This type of system keeps food material safe from contaminants like dust and dirt particles. It also ensures that your material isn’t exposed to ambient conditions, preventing degradation, damage, and similar. A bonus feature of an enclosed system is that it reduces dust levels in the plant. Even when this system is not in use, it will still protect your operation by keeping harmful particles away.

The only downside to an enclosed system is that it can’t be easily inspected without stopping the conveying system (unless the enclosure is transparent or has an inspection section for material view during transport). However, this isn’t necessarily a deal-breaker since most food processing facilities don’t allow their workers near moving machinery.

Top-Notch Design Minimizes Contamination Risks

Food-grade automated conveyor systems should have as few nuts, bolts, holes, cracks, and crevices as possible. These openings are troublesome because they provide a place for contamination to hide in between shifts or after cleaning (if your facility isn’t using clean-in-place technology).

A good way to know how many of these features your system has is to look at the conveyor’s design. A solid, clean system should be designed with minimal components and no removable parts (screws or fasteners).

There should be no places for bacteria or fungi to grow because the conveyor’s surface should be smooth. It can still have a section that is enclosed but transparent for viewing materials as they are conveyed within the system.

Clean-In-Place (CIP) Technology Is Versatile and Space-Efficient

A clean-in-place system is an incredibly important feature of any conveyor that will transport food materials due to strict sanitation regulations in most countries. Food safety requirements demand that conveying systems be regularly cleaned to maintain proper food hygiene.

CIP technology with cleaning conveyor belts keeps your equipment sanitary by automatically cleaning it with pressurized water, steam, or other chemicals. Its main benefit is that you don’t have to disassemble your conveyor. This means less downtime, which will keep your facility’s production levels high.

Space-Saving Solutions for Enhanced Sanitation in Smaller Operations

This technology is also ideal for smaller businesses that might not have enough space to set up complicated cleaning equipment. The CIP system can fit in most areas of a conveyor track without taking too much room away from other systems (for example, material rolls and scissor lifts).

Even if your facility doesn’t use a conveying system for foods, you should still implement CIP technology on all of the other conveyors in your building. This will ensure that they are clean no matter what kind of material is transported through them.

Stainless Steel Connectors Are the Optimal Material Solution

Another factor to consider is whether or not the conveying system is constructed out of suitable materials. As a material, stainless steel is resistant to corrosion and rusting. This is why it’s an excellent option for connectors on conveying systems that transport food materials, as they will almost always come into contact with water or another wet substance like meat juices.

Belt conveyor manufacturers know that the stainless steel connector should be completely smooth without any gaps between the metal surfaces. These spaces are places where contamination can hide and build up over time. The connector should also have minimal bolts or screws, which provide an opening for bacteria to grow in between uses. Stainless steel connectors without a lot of fasteners are ideal because they will keep your system sanitary longer than one with more hardware connections.

Explore Some of the Best Conveying Options

Now that we’ve established the most important features of sanitary industrial conveyor systems, here are the best options to consider. Depending on their providers and design, they could all have clean-in-place technology, stainless steel connectors with minimal bolts or screws, and an enclosed design for protection from dust particles.

Tubular Drag Cable & Disc Conveyors

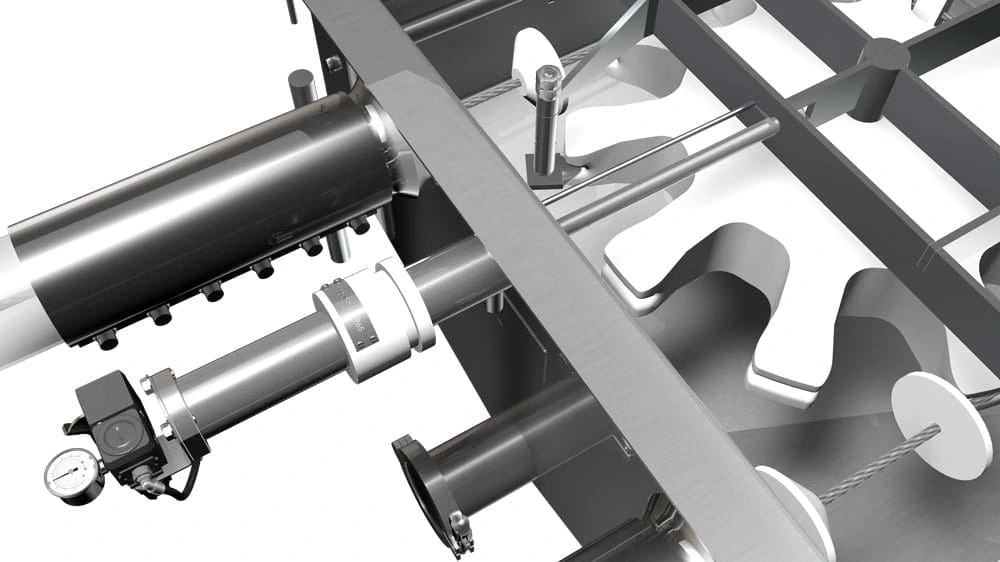

Tubular drag cable conveyors are top-of-the-line when it comes to food-grade material handling systems. They’re made with stainless steel cables for the clean and smooth transport of food materials. What’s more, the steel cables are encased in a nylon jacket, which provides a smooth surface that’s easy to clean. Nylon is also resistant to the growth of bacteria and fungi between uses, which will keep your system sanitary throughout its lifespan.

These manufacturing conveyor systems are enclosed, so you don’t have to worry about dust particles or other contaminants getting into the system if it’s located in an open area like in the production lines. Material is moved with the help of evenly-spaced circular discs that move along with the steel/nylon cable.

The discs are solid, without any holes, making it hard for contaminants to grow in between uses. Cablevey tubular cable conveyors are specially designed for maximum flexibility and can be installed in many different configurations to suit your needs. Our wet and dry cleaning options also make them a great choice for food processing conveying systems.

Tubular Drag Chain Conveyors

Like tubular cable conveyors, tubular drag chain conveyors use chains and discs to move food materials. Thus, it conveys materials through an enclosed tube and can be outfitted with different cleaning technologies.

However, the main difference here is that the chains come directly in contact with the food material. This leads to the accumulation of food particles and liquids that can create a breeding ground for bacteria and other contaminants. Furthermore, it can be hard for the chain to get completely clean, even with advanced cleaning technologies.

Conveyor Belt Systems

A classic belt conveyor system can be enclosed, just like bucket elevators. It’s ideal for moving solid food material through a system, though it comes with a range of limitations. Firstly, a conveyor belt system can’t function at a high angle. It either has to be horizontal or only slightly angled. This severely limits its application and makes it convenient only for plants with plenty of available floor space.

Secondly, they can only transport food materials of a certain size and weight due to the range of belt tensions required for efficient operation. In general, belts must be as tight as possible without breaking or slipping off their rollers (pulleys). However, this could lead to quality issues with larger pieces of food material because it doesn’t allow them to move freely.

Additionally, the belt is in direct contact with food material, which can lead to contamination and bacteria growth if it’s not properly maintained. It also needs regular cleaning because of this reason.

Pneumatic Conveyors

A variety of food materials and products can be conveyed with pneumatic conveying systems. They include solid or liquid food material that’s moved through a tube by compressed air, pneumatic actuators, and the help of gravity.

However, this type of automatic conveyor system is not ideal because it can lead to significant product degradation. Pneumatic conveyors function based on the principles of pressure and suction. The compressed air that moves the food material can be extremely forceful, compromising material and product integrity.

Pneumatic conveying systems could be a good choice for some food processing applications, but only if the product is very durable or if it doesn’t matter if the integrity of the product is compromised. Furthermore, pneumatic tubes could be challenging to access for proper cleaning, especially if the conveying system is not outfitted with a CIP (clean-in-place) system.

Bucket Elevators

Even though the immediate association with bucket elevators is the open-style bucket elevators, there are also closed-style ones on the market. These conveying systems consist of a rotating drum with buckets attached to it that move vertically or horizontally along its axis.

As they ascend or descend, the food material is transported from one point to another within the system. However, because these components directly contact the food, they can lead to contamination and bacteria growth. An additional disadvantage to bucket elevators is that they are difficult to clean and maintain. The cost of this can be seen through downtime for maintenance checks and extended periods of cleaning.

Choose Cablevey Conveyors – One of the Best Conveyor Systems Manufacturers

Sanitation is crucial for food processing conveying systems. If the components aren’t properly maintained or cleaned, food particles and liquids can create a breeding ground for bacteria. Ensuring that your production facilities meet the highest sanitation standards is critical in preventing contamination and foodborne illness.

The most sanitary conveyor manufacturing is a closed-style system with enclosed tubes, clean-in-place technologies to thoroughly clean equipment, and minimal exposure to moving parts that come into direct contact with food material. These systems are the most efficient for food processing.A conveying system that fits this description is Cablevey’s tubular drag cable conveyor. It is fully enclosed, has wet or dry cleaning technologies for thorough cleaning and maintenance, and is made of solid components that don’t compromise food quality. If you’d like to learn more about conveyor sanitation and solutions provided by Cablevey Conveyors, don’t hesitate to contact us.