Cablevey Conveyors, a global leader in tubular drag conveying systems, has announced the launch of two customer-driven retrofit solutions designed to reduce product loss and improve operational efficiency – CleanDrop™ and CleanTray™. The innovations mark Cablevey’s first significant product introductions since becoming part of Akona Process Solutions, the newly unified material handling group that includes Cablevey, Kason, Marion and Spiroflow.

Both new products reflect Cablevey’s ongoing commitment to listening to customer challenges, particularly in sectors such as coffee, nutraceuticals and fine powders, and responding with practical, engineering-led solutions that reduce waste, improve efficiency and protect margins.

CleanDrop is designed to address the issue of carryover, which is residual product that clings to conveyor discs and escapes past the intended discharge point. Using a simple, but highly effective mechanism, the system gently agitates the discs as they pass through a specially designed discharge tube, shaking free any clinging product. Initially developed for the coffee industry, lab tests using ground coffee demonstrated a tenfold reduction in carryover, resulting in significant improvements in yield and cleanliness. Importantly, CleanDrop is fully retrofittable, meaning that existing Cablevey systems can be upgraded with minimal disruption, requiring only a replacement tube and straightforward installation.

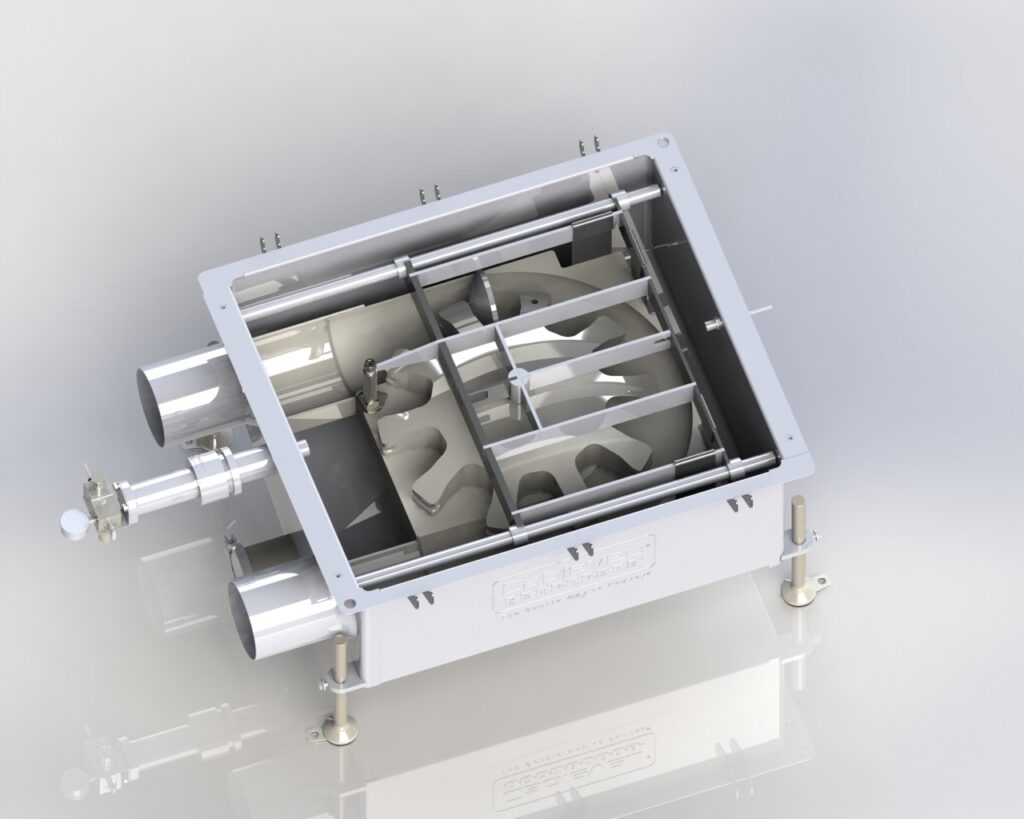

The second innovation, CleanTray, addresses another key issue – product loss within the conveyor’s turnaround section. Traditionally, material that reaches this point can escape the flow path and become waste. Cablevey’s new CleanTray captures that residual product and recycles it back into the system, ensuring nothing is lost. The three-piece design allows the tray to move naturally with the system’s carriage while maintaining a consistent product path. Like CleanDrop, it is also retrofit-ready, offering a cost-effective solution for improving efficiency in legacy installations.

“These are smart, low-cost upgrades that deliver real value,” said John Adair, Akona’s new product development engineering manager. “By focusing on problem points in the conveying process, such as carryover and turnaround loss, we’ve engineered solutions that help our customers reduce waste, improve yield and make the most of every batch. And because they’re retrofittable, there’s no need to invest in a new system to see the benefits.”

With both solutions already in use at major coffee production facilities, Cablevey is now taking orders globally. The launch highlights Akona’s ongoing commitment to provide integrated, high-performance material processing systems supported by reliable, specialized expertise.

For more information on Akona and its brands, visit https://akonasolutions.com/ ou Contactez-nous