Performance Retro Kit

Welcome to the forefront of conveyor system optimization with Cablevey Conveyors’s groundbreaking Performance Retro Kit. Designed to elevate the efficiency and extend the lifespan of your tubular conveying system, our innovative kit introduces cutting-edge solutions to propel your operations to new heights. Experience unparalleled performance enhancements and competitive advantages for your products and services with this conveyor manufacturing kit.

Revolutionizing Conveyor Technologies Like Performance Retro Kit Will Boost Your Operations

Upgrade your Cablevey tubular drag conveyor system with our latest innovation, the Performance Retro Kit. Experience enhanced performance and extended product life while propelling your industry with unparalleled competitive advantage for your products and services.

Optimizing Tension Control With Pneumatic Systems

The pneumatic tensioning system is composed of a pneumatic cylinder, a regulator with a dump valve, and a gauge. Adjusting the regulator allows the operator to increase or decrease the tension on the cable. The pneumatic tensioning system offers advantages over a spring tension system whether you have a 200 series or a 300 series.

If your 200 series system is unstable due to the length of the system or frequent buildup, a pneumatic tensioning system may be able to offer the additional tension you require. For the owners of a 300 series, the pneumatic tensioning system offers much more fine adjustment than the torsion springs.

Additionally, tension adjustments can be made while the system is still running, and access space behind the turnaround is no longer required. Whether conveyor systems manufacturers have the system shut off due to insufficient tension or you shut it off to make adjustments, this downtime costs you money.

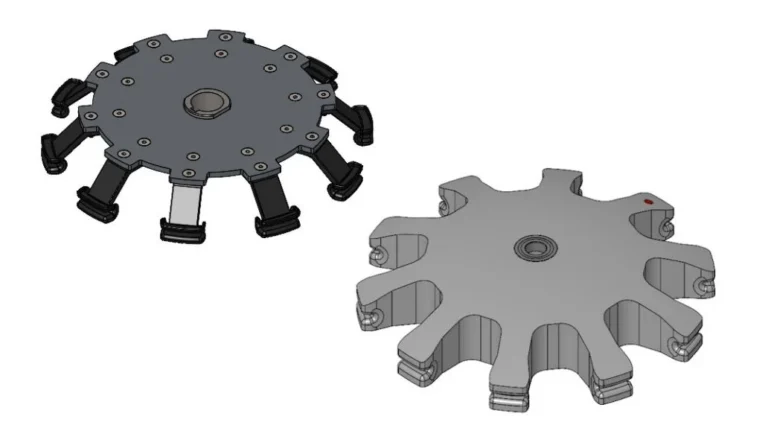

Maximizing Cable Lifespan With Polymer Sprockets

The most expensive single component of a Cablevey Conveyor system is the cable. The traditional belt conveyor system, as you can assume, has belts, and the most previous components were precisely belts.

Now as a worn item, the cable requires occasional replacement. However, one way to extend the cable life is to make the switch from stainless sprockets to polymer sprockets. The low friction polymer employed in these sprockets is less abrasive on the cable, increasing cable lifespan.

While more gentle on the cable, polymer sprockets will require more frequent replacement than stainless. This is not a solution for every customer, including those moving a highly abrasive product or operating at higher temperatures, but this is an easy improvement for many customers.

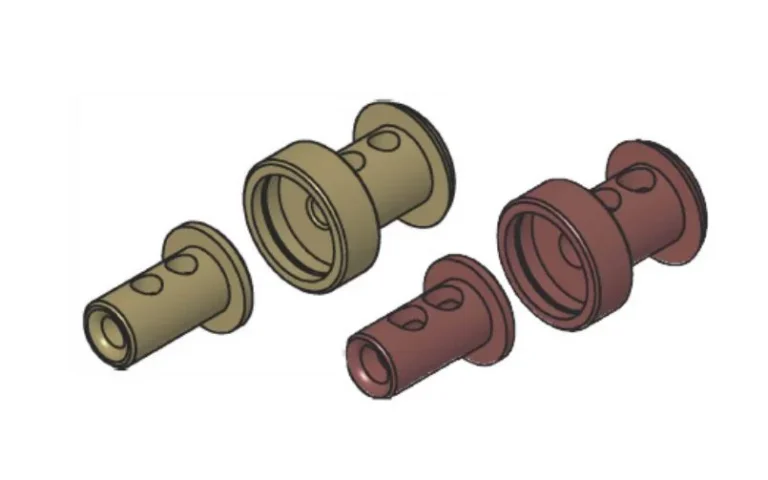

Enhanced Cable Connector Design for Extended Lifespan

With our redesigned cable connector, customers can expect the cable to last much longer. The new design decreases the stresses where the cable bends in the male connector, increasing the life of the cable in this joint to ten times as long. Most of our customers have already made this switch and have experienced great gains in cable life. If you haven’t, you are missing out!

Our connectors are coated with a food-safe durable coating, letting us color-code the different sizes of connectors we offer for the different sizes of cable. See the following section for more information on 5/16” coated cable.

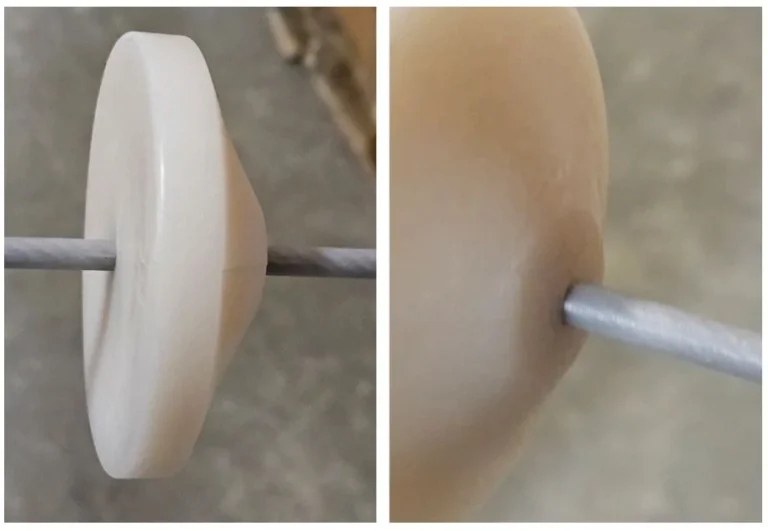

Innovative Sanitary Solution - 1-Piece Coated 5/16” Cable

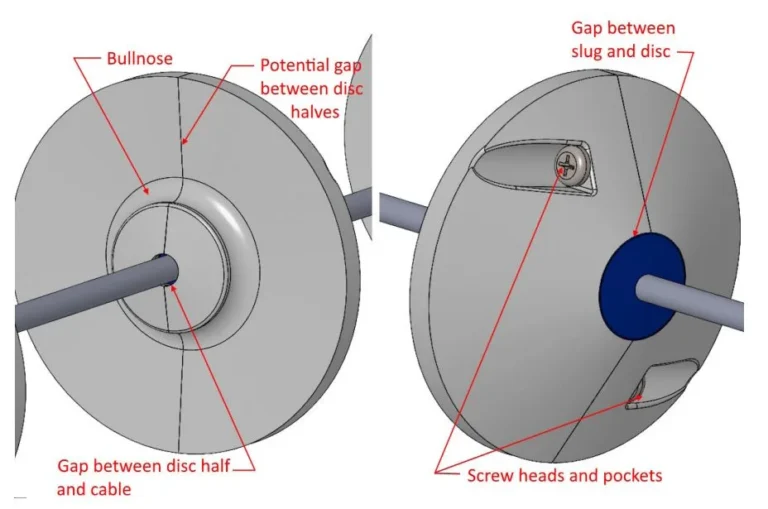

In an effort to improve sanitary installations for our customers, Cablevey Conveyors has developed a 1-piece coated 5/16” cable. One-piece discs are injection molded directly onto the cable, unlike the 2-piece discs that are manually assembled to the cable. The molded plastic creates a tight seal between the disc and the cable, reducing the likelihood of food harborage and pathogen growth.

The surface of the 1-piece disc of an automated conveyor system is smooth and offers no nooks or crannies where food products can build up, harbor allergens, and foster the growth of pathogens. Two-piece discs have screw holes and potential harborage in gaps.

These features of the 1-piece disc improve the cleanability by brushes and air-knives, and water easily runs off the surface for a wet clean. Just like the cleaning conveyor belts do for the conveyor belt system, this feature does the same for the Retro Kit.

Advanced Cable Coating Technology for Extended Lifespan

We’ve also nearly perfected our cable coating materials and process. Our cable coating retains the cable lubricants and protects the load-bearing metal portion of the cable from direct contact with abrasive materials and action. This coating extends the lifespan of a bare cable many times and is very durable. It serves as a diagnostic tool, forewarning the customer that the cable or the coating is reaching their end of life. Sudden failures of cable and coating have all but stopped.

In the last few years, we have standardized on a 5/16” diameter coated cable. The heavier cable resists stretching better than the earlier 1/4” coated cable, increasing stability for longer and harder-pulling systems. If the cable is allowed to stretch significantly between being loaded and unloaded, the system is less tolerant of any mild hiccup that might occur and may shut off over what seems like nothing. Talk to your sales rep today about this.

Experience Superior Tubular Conveyor Solutions Today

Upgrade your industrial conveyor systems with Cablevey Conveyors’ Performance Retro Kit and revolutionize your operations. Contact us now to speak with our conveyor engineering experts and discover how our innovative solutions can elevate your manufacturing conveyor systems processes.

Your comprehensive kit includes critical components designed to maximize the efficiency and productivity of your Cablevey Conveyor system. Download the detailed brochure to learn more and get started on optimizing your conveyor systems’ performance.

Download Detailed Performance Retro Kit Brochure

Improve The Performance Of Your System