Cable Conveyor Tensioning Options

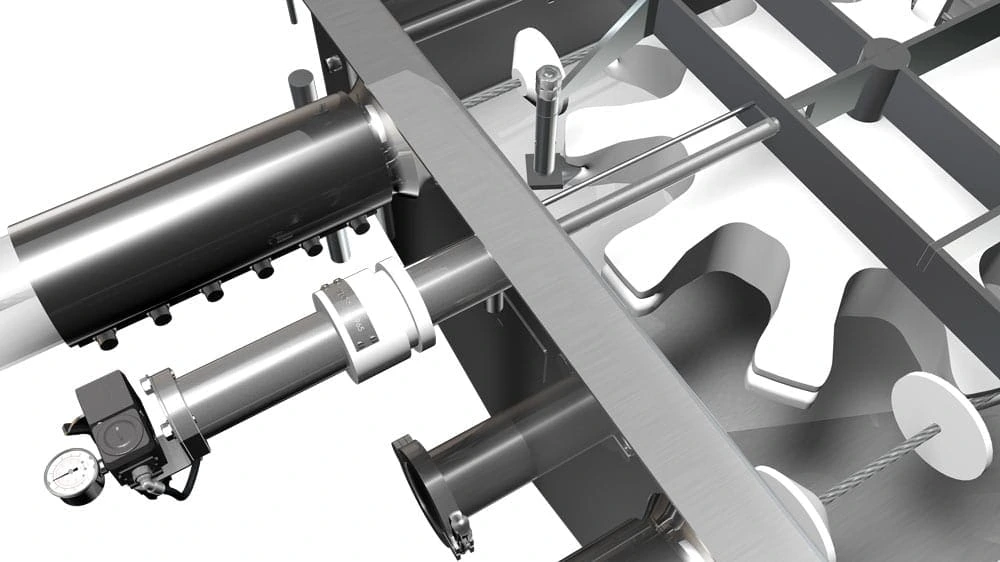

Pneumatic Tensioning Air Cylinder

The role of pneumatic tensioning devices, such as the pneumatic tensioning air cylinder, is to manage cable tension in pneumatic conveyor systems. They are essential to the overall longevity, dependability, function, and power of Cablevey’s tubular cable and disc drag conveyor belt system. Too low tension setting and the cable might disengage from the sprocket, triggering a system malfunction. Too high cable tension, on the other hand, and you can expect more energy usage, wear, and other problems caused by excess friction.

5 Reasons to Use a Pneumatic Tensioning Device

Cablevey Conveyors improved methods for cable-tension management in bulk material handling equipment. With these improvements, more accurate control of tension is made much easier. That was done by putting a pneumatic cylinder in place of the stainless steel springs, and it proved the accurate cable tension over the whole range of travel. Other advantages of a pneumatic tensioning device in a custom conveyor belt for a food system include the following:

Automatic Settings

A low tension sensor gives you a visual alert in case the cable tension is too loose and will shut down the system automatically.

Adjustable Tension

It allows operators to control pressure while the machine operates and adjust it depending on products or production flow. Also, running cleaning devices during the sanitation process might require more tension.

Easy To Use

The operator is able to set tension simply by turning a knob while looking at the pressure gauge. There is a lot less complexity to controlling the tension.

Less Maintenance

With more accurate and specific control over cable tension, the need for maintenance will lessen, while conveyor performance will increase.

Constant Tension

A pneumatic piston provides constant tension over the whole range of travel through the belt conveyor system and other parts of the conveyor.

Pneumatic Tensioning Air Cylinder Specifications

Dimensions

Weight

Power Required

Air Required

Range of Force Output

4” X 4” X 24”

15 pounds

Compressed Air

< 1 cfm

0 – 300 lb.

Frequently Asked Questions

What Is the Purpose of a Pneumatic Tensioning Air Cylinder in Conveyor Systems?

A pneumatic tensioning air cylinder is vital in managing the cable tension in conveyor systems. Proper tensioning ensures the longevity, dependability, and efficient power utilization of Cablevey’s tubular cable and disc drag conveyor belt system.

What Are the Primary Benefits of Using a Pneumatic Tensioning Device?

Using a pneumatic tensioning device offers several advantages, including automatic settings with low-tension sensors and adjustable tension for various products or production stages. It also provides ease of use with simple controls, reduced maintenance, and consistent tension throughout the entire conveyor system, enhancing the performance of automation conveyor systems.

Do Pneumatic Tensioning Devices Fit All Sizes of Tubular Conveyors?

Pneumatic tensioning devices are specifically designed to accommodate various sizes of tubular conveyors to enhance their efficiency and longevity. Currently, our pneumatic tensioning devices can be installed in our mini 4, 4- and 6-inch conveying systems.

Are There Any Technical Requirements Necessary to Pneumatic Tensioning Device Installation?

For the successful installation and operation of a pneumatic tensioning device, the primary technical requirement is the availability of an air compressor. This air compressor serves as the power source for the pneumatic cylinder, facilitating the adjustable and constant tension settings that are a hallmark of the system.

How Much Compressor Airflow Capacity Does a Pneumatic Tensioning Device Require?

While a pneumatic tensioning device requires airflow to operate, it is designed to be highly efficient. That is why only a minimal amount of airflow is required to serve as a holding force inside an industrial conveyor belt for a warehouse or a custom conveyor belt for food. This airflow serves as a holding force, maintaining the correct level of tension throughout the conveyor system to prevent malfunctions and ensure smooth operations.

Learn More About Our Systems