ROI Calculator

Are you looking to determine your potential savings by reducing your maintenance hours? By eliminating 700 hours of maintenance, you could save thousands of dollars. Additionally, replacing your current conveyor system could bring about other advantages. Consider the benefits such as reduced product breakage and value losses, decreased maintenance time for downtime and cleaning, and improved energy efficiency.

We have created a series of ROI calculators specifically designed by our experienced Cablevey engineering team. These calculators are based on over 50 years of expertise in helping customers identify cost savings. They will assist you in making an informed decision based on your facility’s needs and the products you are conveying.

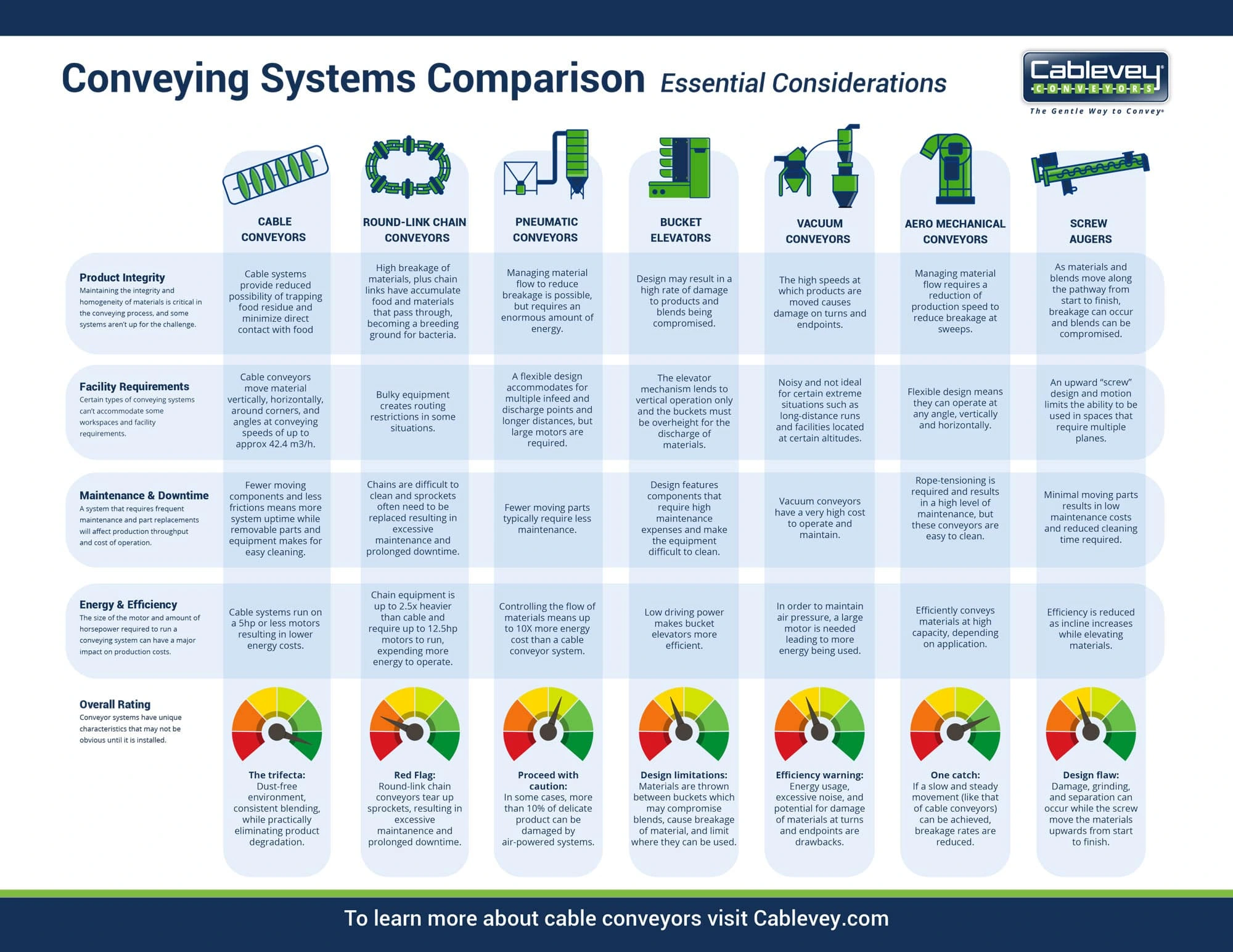

Chain Vs. Cable Conveyor ROI Calculator

Chain Conveyors: Calculating important factors like capacity, layout challenges, durability and maintenance, line changeover, energy consumption, are key to the ROI formula so you can make an informed decision that aligns with your production goals and budget.

Aeromechanical Vs. Cable Conveyor ROI Calculator

Aeromechanical conveyors use high-speed wire rope with discs to create an air stream that carries particles without much contact.

Screw Vs. Cable Conveyor ROI Calculator

The screw pushing product in the tube creates friction, which limits conveyor length. Moving the product over long distances requires a lot of torque, which can impact the screw's design and materials. Longer screws may sag or buckle without support bearings, affecting flow.

Bucket Vs. Cable Conveyor ROI Calculator

Bucket conveyors use buckets attached to belts or chains to transport products horizontally and vertically. There are two styles of buckets, each with its own advantages and disadvantages.

Pneumatic Vs. Cable Conveyor ROI Calculator

Dilute Phase conveying, low-pressure air with high velocity carries the product in suspension. Dense Phase conveying uses high-pressure air, method pushes a thick slug of material through the tube.

Vacuum Vs. Cable Conveyor ROI Calculator

Vacuum conveying systems and dilute phase systems are similar, but the primary difference lies in the blower's location. Vacuum systems are ideal for conveying small product amounts compared to dense phase systems. While vacuum systems are less likely to leak due to their negative pressure, any leaks can potentially introduce contaminants into the system.

Cablevey Conveyors vs. Other Conveyors

When it comes to moving materials around, the right automated conveyor system can make all the difference. Comparing Cablevey Conveyors vs. other conveyors can show you all about their design, how they work, and why they might be the better option for your needs. Whether you’re moving coffee beans, nuts, or even delicate electronics, understanding the differences can help you make a smart decision.