Cablevey Conveyor Components

Have you ever wondered how products in a factory get from one point to another? The secret lies in a conveyor belt system. One type of these amazing machines is called the Cablevey Conveyor System, manufactured at Cablevey® Conveyors. So, let’s take a look at Cablevey conveyor components to understand the intricacies of each belt conveyor system we produce.

What Are Industrial Conveyor Belt Systems?

Conveyors are bulk material handling equipment designed to transport items across various points in a manufacturing, packaging, or distribution environment. They come in diverse types, including belt, roller, and cable conveyors, to name a few. Each type is unique and has been built to suit different purposes, material types, and industrial settings.

What Are Industrial Conveyor Belt Systems?

Industrial conveyor belt systems bring numerous benefits to a wide range of industries, contributing to increased efficiency and productivity. Here are some key advantages:

- Conveyors can transport a large volume of materials over a consistent speed, reducing the time and effort compared to manual labor.

- Once installed, they can reduce labor costs by automating tasks that would typically require manual effort. In addition, they can operate continuously, maximizing production capacity.

- Conveyor systems can handle a wide variety of materials, from small delicate items to large, heavy ones. They can also be adapted for a range of industrial environments and production requirements.

- By applying automation conveyor systems, they minimize the risks associated with manual handling, such as accidents and injuries.

- The continuous and controlled operation of conveyors enables a smooth flow of materials, increasing overall productivity.

- Conveyor systems can be expanded or reconfigured to meet evolving production requirements, making them a scalable solution for growing businesses.

- Since they provide a controlled and consistent flow of materials, they can minimize product damage that can happen with manual handling.

- Conveyors can move materials across different stages of the manufacturing process (from production to packaging to shipping) in a streamlined and organized manner.

To sum it all up, whether it’s a conveyor belt for a warehouse or a conveyor belt for food, these systems are an invaluable asset for many businesses, helping enhance efficiency, safety, and productivity.

Key Cablevey Conveyor Components

The manufacturing world is a diverse arena where efficiency and flexibility reign supreme. At Cablevey, we understand this dynamic environment and have built conveyor systems that meet the industry’s evolving demands. Our cable conveyor systems boast a range of key components that are highly adaptable and modular, designed to provide seamless integration and easy access to suit various factory floor needs.

They are also highly flexible and modular to facilitate easy access for factory floor needs. These components, which form the heart of our conveyor systems, include drive units, funnels, inspection sections, and more. Each part is meticulously crafted to ensure smooth operation and maintain the system’s overall performance.

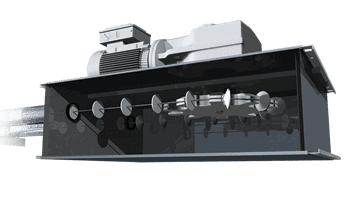

1. Drive Unit

The cable is pulled through the drive unit by an electric gear motor mounted to a stainless steel frame. The cable can enter and exit through either tube port as required for your layout.

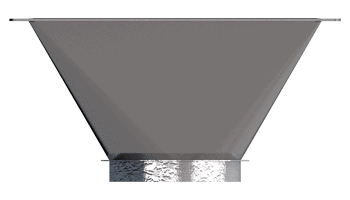

2. Funnel

Funnels are used to discharge material from rotary discharges and/or cleanouts. Funnel outlets are available in a wide variety of sizes and connection types to fit your needs.

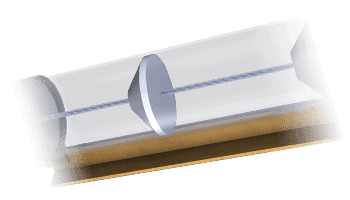

3. Inspection Section

The inspection section is a food-grade plastic tube that allows you to see the product conveyed and observe the cleaning process. They can be installed in vertical or horizontal runs as desired.

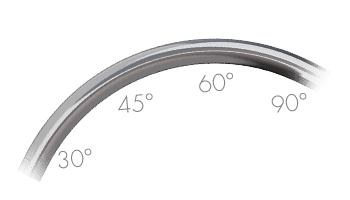

4. Sweep

Sweeps change transport to any desired direction. Sweeps are available in many angles from 0-90 degrees and in several different radius dimensions to fit restricted spaces.

5. Compression Coupler

The coupler’s food-grade rubber gasket ensures a good seal against air, water, and dust. The coupler holds the tubes together in perfect alignment to provide the discs with a smooth path.

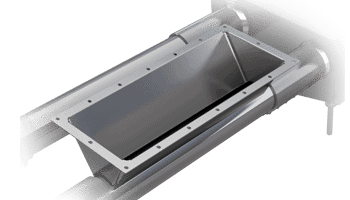

6. Inlet

Inlets are available in a wide variety of lengths to accommodate various needs. The sides of the inlets are available in different slopes to accommodate different material flow properties. Multiple inlets may be used if desired.

7. Turnaround

The turnaround contains a sprocket that facilitates reversing cable direction from the return side of the system to the product conveying side. The sprocket is mounted on a mechanism designed to provide proper cable tension.

8. Discharge

The discharge has the ability to be open or closed, allowing materials to either pass through or exit the conveyor at that point.

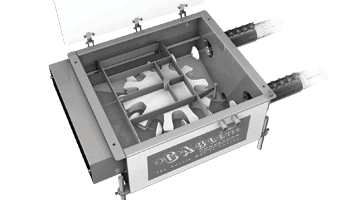

9. Brush Box

A brush box is a housing that the cable and discs pass through. The brush box contains two roller brushes mounted above and below the cable and discs. As the cable moves through, the discs turn the brushes removing any clinging particles into a waste chute for disposal.

Why Choose Cablevey Conveyor Systems

The versatility and efficiency of Cablevey Conveyor Systems can revolutionize the way materials are transported in your manufacturing business, streamlining all your processes. They will provide a blend of engineering and innovation, bringing you much-needed solutions that are efficient, scalable, and cost-effective. From the tiniest ingredient in a food factory to the heaviest component in an industrial assembly line, Cablevey Conveyors have proven time and again that we are up to the task.

If you’re looking to transform your production line and improve efficiency, we invite you to consider the value that our conveyor systems bring. With Cablevey Conveyors, you’re not just investing in a conveyor system – you’re investing in smooth operations, safe material handling, and, ultimately, the success of your business.

Ready to experience the Cablevey difference? Contact us today for more information, and let’s start a conversation about how we can tailor our solutions to meet your specific needs.

FAQ

What Are the Main Components of a Cablevey Conveyor System?

These systems primarily consist of a drive unit, funnel, inspection section, sweep, compression coupler, inlet, turnaround, discharge, and brush box.

How Does the Cable Play a Role in the Conveyor System?

The cable in a Cablevey Conveyor System serves as the transport medium. It is connected to multiple discs and driven by a motor, pulling products along in the enclosed tube.

What Is the Function of the Discs in a Cablevey Conveyor?

Discs in a Cablevey conveyor help in carrying the material. They push the product through the tube and are specifically designed to minimize friction and prevent damage to the product.

Are There Different Types of Cables and Discs Available for Different Applications?

Yes, different types of cables and discs are available for different applications. The variation mainly depends on the type of materials being transported, the weight, and other specific needs.

How Do Tube Materials Impact the Performance of the Conveyor System?

Tube materials directly impact the durability, maintenance, and in some cases, the type of product that can be transported. Different materials like stainless steel, carbon steel, or plastic can be used based on application needs.

Can the Conveyor Components Be Customized for Specific Requirements?

Yes, conveyor components can often be customized to meet specific requirements, such as adjusting the size, material, or configuration to handle specific types of products.

Are There Any Maintenance Requirements for the Conveyor Components?

Regular inspections and maintenance are required to ensure optimal functioning. This can involve checking for wear and tear, cleaning, lubrication, and replacement of worn-out components.

What Is the Typical Lifespan of the Cable and Discs?

The lifespan of the cable and discs depends on the usage, maintenance, and type of materials being transported. However, with proper care, they can typically last for several years.

Can the Conveyor Components Be Easily Replaced or Upgraded?

Yes, conveyor components can be replaced or upgraded as needed. This flexibility allows for system optimization and adaptation to changes in production requirements.

How Do the Conveyor Components Contribute to the Overall Efficiency of the System?

The efficiency of the system is directly related to the performance of its components. Efficient components ensure smooth operation, reduce energy consumption, prevent product damage, and enhance overall system productivity.

Let's Get Started