The Cablevey and Automated Handling Solutions teams are excited to publish the 2nd annual State of Conveying Research Study, the only research study exclusively covering conveying for food processing professionals. The State of Conveying for the Food Processing Industry 2023 report provides trend analysis and new findings regarding the food processing industry and how organizations convey food products in their facilities.

Learn About the State of Conveying for the Food Processing Industry in 2023 With Cablevey’s Detailed Research

In modern food processing plants, conveying foods has evolved into a finely tuned process prioritizing efficiency, hygiene, and safety. As food processing continually embraces innovation, industry professionals are committed to making the best decisions for their specific conveying needs. To make those decisions, the industry needs data. The State of Conveying for the Food Industry 2023 builds on findings from 2022 to provide you with new and updated data to make the best decisions moving forward.

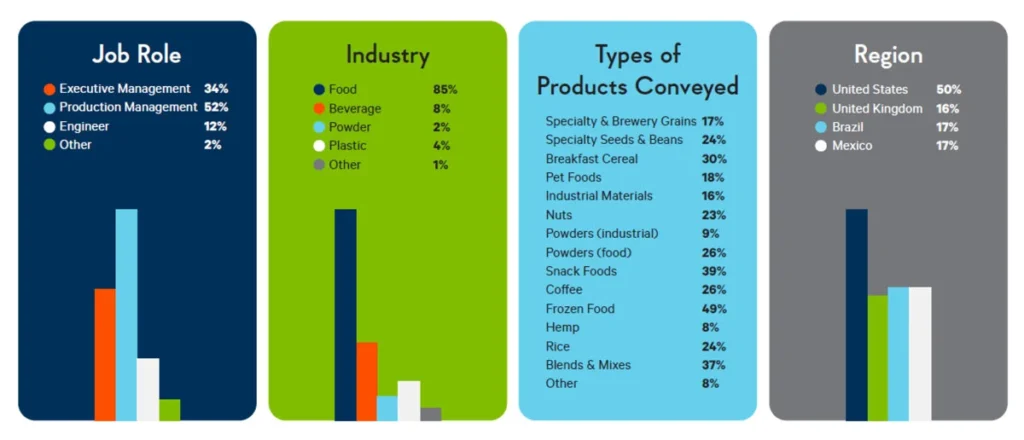

In July 2023, Cablevey Conveyors commissioned the independent research firm Ascend2 to conduct the 2023 research study. The 21-page study asked 327 food processing professionals in the United States, United Kingdom, Brazil, and Mexico to provide insight into the industry outlook and challenges, cleaning and maintenance of systems, the purchasing process, budgeting, and more.

What Are the Key Findings for 2023?

Cleaning and maintenance are the number one top-reported challenge faced in the food-processing industry, according to 53% of those surveyed. 97% of those surveyed agree they would benefit from finding a more efficient way to clean conveying systems. Our study takes a deep dive into this topic and provides actionable next steps for you to consider as you plan the next steps for your facility.

61% of those surveyed have shopped for or purchased a new conveyor system in the last year, and 82% plan to update or replace parts of their conveying systems in the next two years. 98% of those surveyed agree that testing products on a new system is critical before deciding on purchasing. We’ve devoted a section of this study to reviewing the purchase process that food professionals are taking to make the best decision for their organization. Let’s take a look at a few insightful charts from the research study.

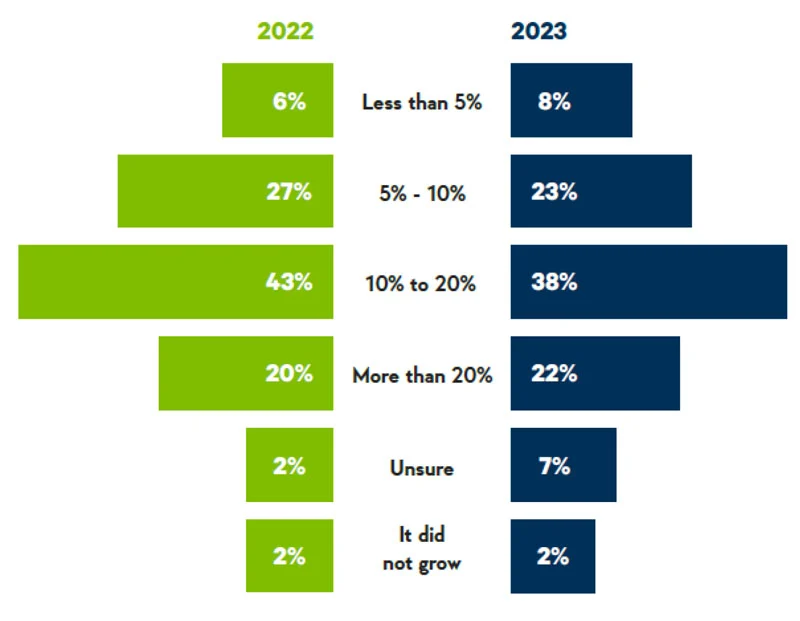

Chart 1: Industry Growth Continues

The food processing industry is rapidly growing, with 63% having grown 10% or more in the past year (20% increased by more than 20%). This mirrors the growth from 2022 and indicates a long-term growth trend for the industry. As the industry grows, it is more critical now than ever for decision-makers to ensure their operations are properly optimized to handle current and future growth.

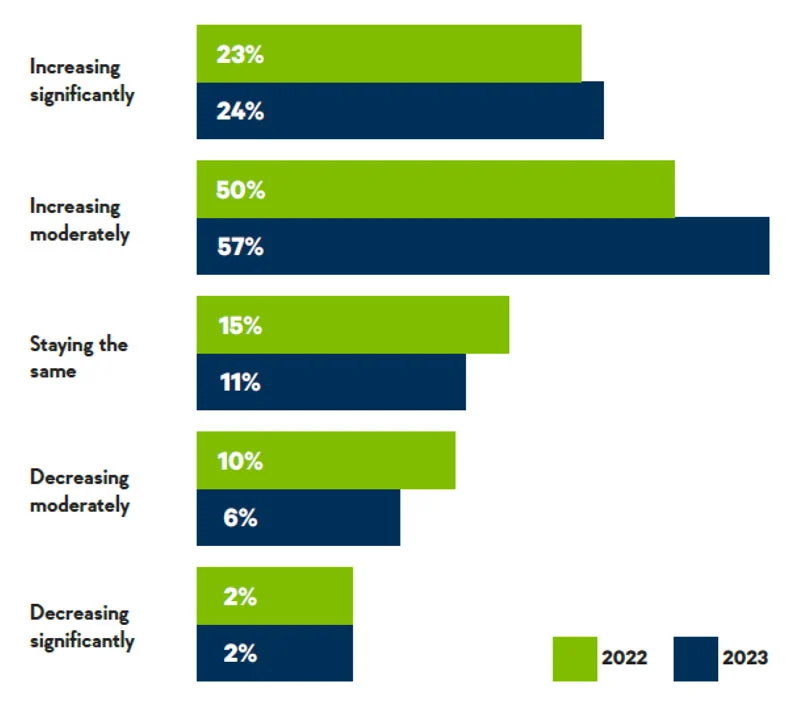

Chart 2: Budgets Increase

Budgets for conveyors and equipment maintenance are changing to meet industry growth demands. 81% of organizations plan to increase their budgets in the next 12 months, continuing the trend from 2022.

How will your budget for conveying equipment and maintenance change in the next 12 months?

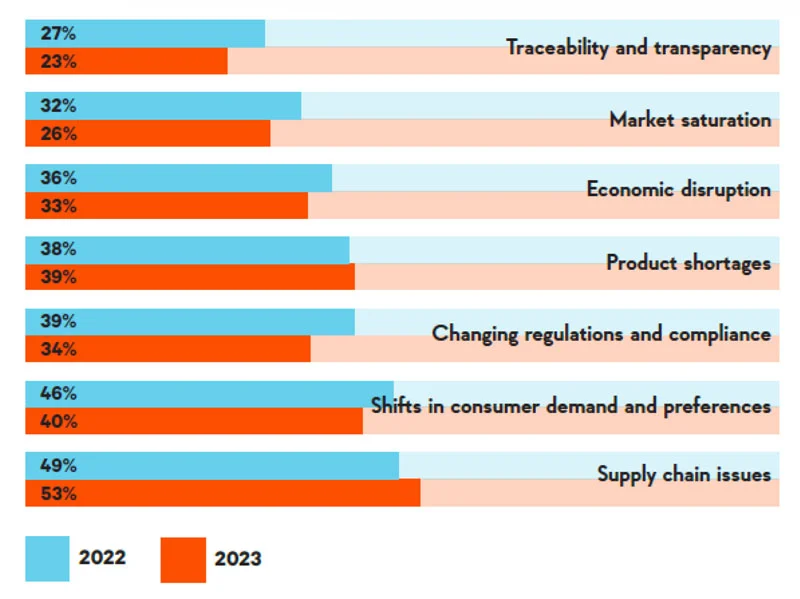

Chart 3: Top Challenges in the Industry

Supply chain issues (49%) continue to be the top challenge in the food processing industry, and shifts in consumer demand and preferences (46%) are a close second. Shifts in consumer demand and preferences experienced a significant jump from 2022, indicating the need for organizations to be agile with their ability to adjust production lines to meet demand.

What do you consider to be the top challenges facing the food and beverage processing industry?

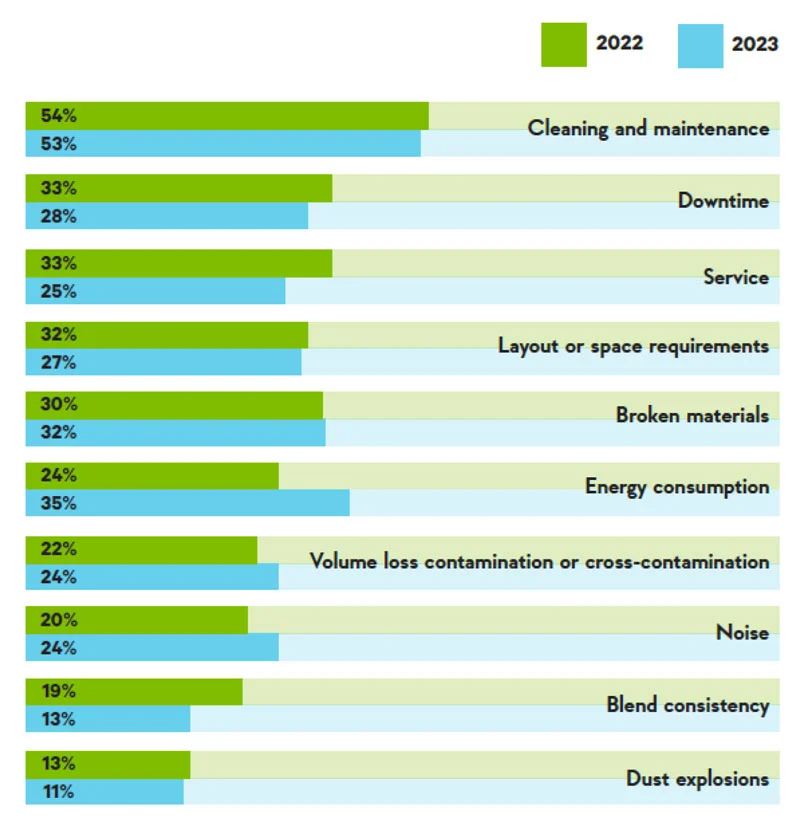

Chart 4: Top Conveying Challenges

Cleaning and maintenance of conveyors come in first at 53%, which isn’t even a close race, with energy consumption coming in second at 35%. Energy consumption and broken materials are also at the top of the list for over one-third of those surveyed.

What are the greatest challenges you face with conveying materials?

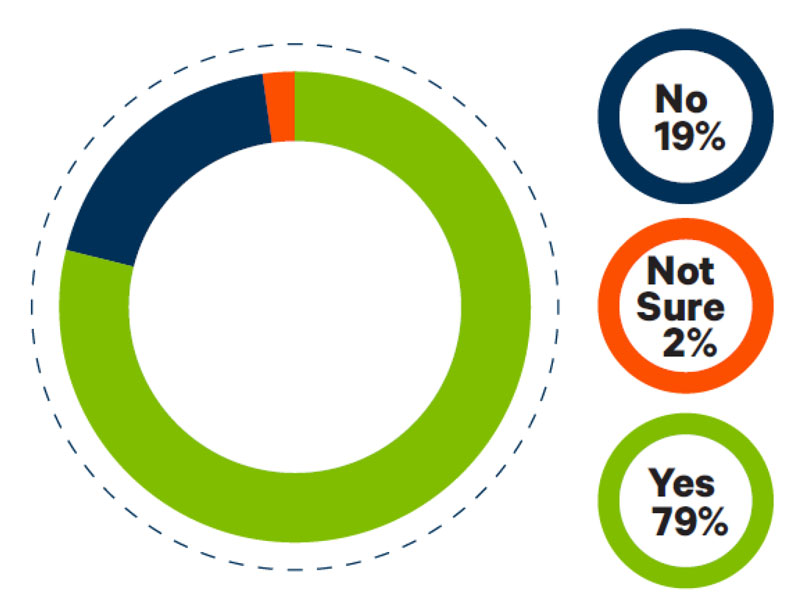

Chart 5: Maintenance Issues Are Top-Of-Mind

97% of those surveyed agree they would benefit from finding a more efficient way to clean their conveying systems. 67% strongly agree. 79% of those surveyed move more than one product through their system, requiring cleaning.

Do you move multiple products through one system that would require the system to be cleaned?

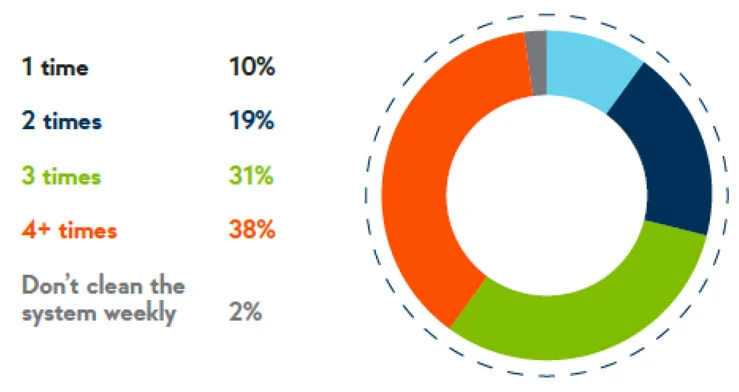

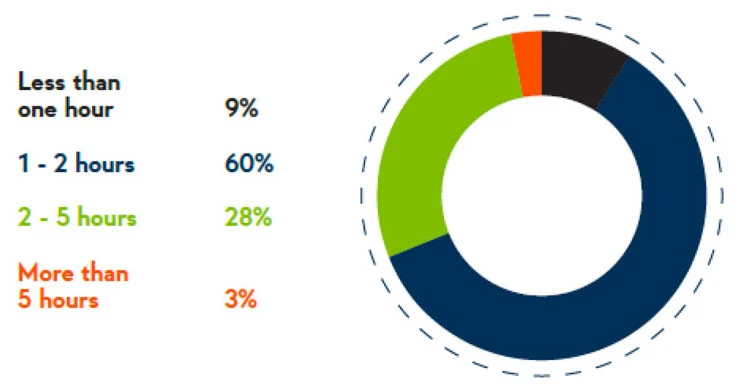

Chart 6: Maintenance Equals Time and Money

Over two-thirds (69%) of those surveyed clean their conveying systems three or more times per week. 38% clean their systems four or more times per week. For 31% of those surveyed, this process takes more than 2 hours. For another 60%, the process takes 1-2 hours.

How many times per week do you clean your conveying system?

On average, how long does it take to clean your conveying system?

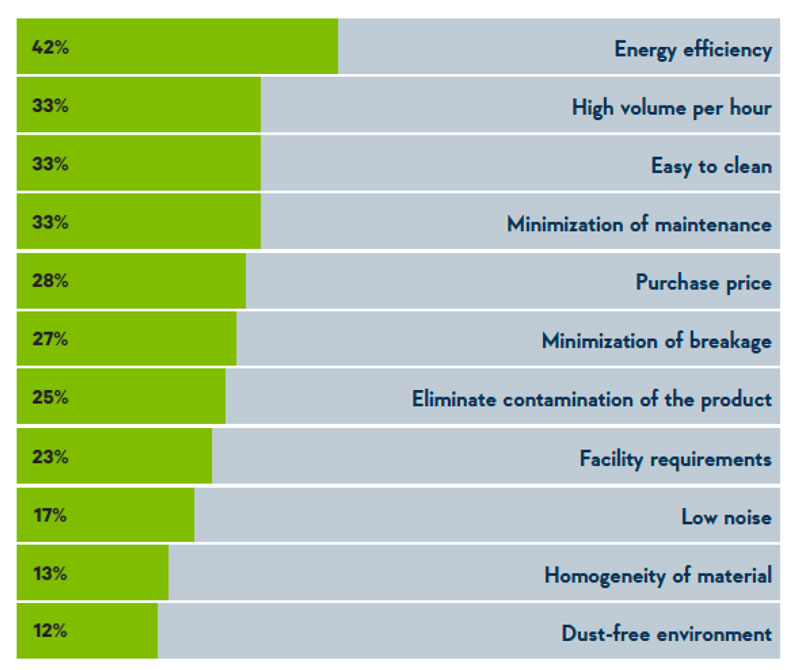

Chart 7: Insights on the Evaluation Process

What are the most critical factors to consider when evaluating a new system? Energy efficiency is the most critical consideration when selecting a new conveyor. Minimizing maintenance and a system that is easy to clean is also at the top of the list of most critical considerations when choosing a new conveying system.

What are the top reasons for updating your conveying processes?

Learn More in Our Detailed Study

Dive deeper into our comprehensive analysis by exploring our detailed study. The seven charts featured in this article represent just a glimpse of the extensive data and insights compiled in our research study. By downloading The 2023 State of Conveying for the Food Industry, you gain access to a wealth of knowledge that covers trends, technological advancements, challenges, and opportunities within the food processing industry.

Our report provides a thorough examination of the current landscape, offering valuable perspectives from industry experts, case studies, and predictive analytics to guide businesses in making informed decisions. Enhance your understanding of the sector’s dynamics and prepare your operations for future developments by leveraging the in-depth analysis provided in our study.

Need New Conveyor Solutions for Your Facility? Contact Cablevey Conveyors

If your facility requires innovative solutions, Cablevey Conveyors stands ready to deliver expert conveyor technologies tailored to your needs. Our specialized tubular conveying system is designed to handle a wide range of materials, from delicate food products to robust industrial materials, ensuring efficient, gentle, and clean transport.

Whether you’re in the food processing, pharmaceutical, or manufacturing industries, our team of experts will work closely with you to understand your specific requirements and challenges. By choosing Cablevey Conveyors, you’re not just getting a conveyor system but a solution engineered for optimal performance and reliability. Contact us today to explore how we can enhance your facility’s operations with our cutting-edge enclosed cable tubular convey.

FAQ

What Are the Key Trends in Conveying for the Food Processing Industry in 2023?

The key trends in conveying for the food processing industry in 2023 include an increased focus on cleaning and maintenance, energy efficiency, and adapting to shifts in consumer demand and preferences. With the industry growing rapidly, there’s also a significant emphasis on updating and purchasing new conveyor solutions to enhance operational efficiency and safety.

Why Is Cleaning and Maintenance a Major Challenge in the Food Processing Industry?

Cleaning and maintenance have emerged as major challenges due to the need to ensure hygiene and safety in the food processing industry. 53% of professionals surveyed identify it as their top challenge, with 97% seeing benefits in finding more efficient cleaning methods. The complexity increases with systems that convey multiple products requiring frequent and thorough cleaning.

How Are Budgets for Conveyor Equipment and Maintenance Changing?

Budgets for conveyor equipment and maintenance are on the rise, with data showing that 81% of organizations plan to increase their budgets in the next 12 months. This trend aligns with the industry’s growth and the need for more advanced, efficient, and reliable conveyors to meet expanding operational demands.

What Factors Are Critical When Evaluating a New Conveyor System?

When evaluating a new conveyor system, the most critical factors include energy efficiency, ease of cleaning, and minimizing maintenance requirements. These priorities reflect the industry’s focus on sustainability, operational efficiency, and ensuring food safety and quality through better conveyor system design and functionality.

How Often Do Food Processing Professionals Clean Their Conveying Systems, and Why Is This Significant?

Food processing professionals clean their conveying systems frequently, with over two-thirds cleaning them three or more times per week. This high frequency highlights the industry’s stringent hygiene standards and the effort to prevent cross-contamination between different products. Efficient cleaning processes are crucial for maintaining product quality and safety.