There is a long list of nuts that may be conveyed in your facility. Almonds, brazil nuts, cashews, hazelnuts, macadamia, peanuts, pecans, pine nuts, pistachios, and walnuts are a few common types of nuts that are consumed globally. Explore the nuts industry trends for 2023 that shape the industry and how a reliable tubular conveying system will help you boost your manufacturing.

In this article, we will review and analyze the findings from 103 food processing professionals who are conveying nuts. What automated conveyor systems are best for the specific needs of conveying nuts? Use these findings and download the report for more information to help prepare for what is ahead in the nut industry.

Challenges in Nut Conveyance – Overcoming Brittleness and Sensitivity

What is unique about conveying nuts? Nuts, characterized by their brittleness and sensitivity to motion and free fall, pose distinct challenges during conveying, particularly with specific methods. Facilities engaged in nut production and processing cater to either a single type of nut or a diverse range for various purposes.

Nuts undergo processing for oils, nut butter, or packaging, finding their way into the market as whole nuts or as essential ingredients in a myriad of food products. The pivotal task of ensuring optimal nut conveyance lies in the meticulous selection of the most suitable conveyor system.

Unveiling the Findings of the Nut Conveyor Solutions

In October of 2022, Cablevey Conveyors enlisted the services of the independent research firm Ascend2 to initiate a comprehensive research study titled “Evaluating and Implementing New Conveyor Systems.” This in-depth 16-page report sought input from 290 food processing professionals based in the United States and the United Kingdom. Their valuable insights were gathered to shed light on the crucial factors influencing the assessment of industrial conveyor systems within the industry.

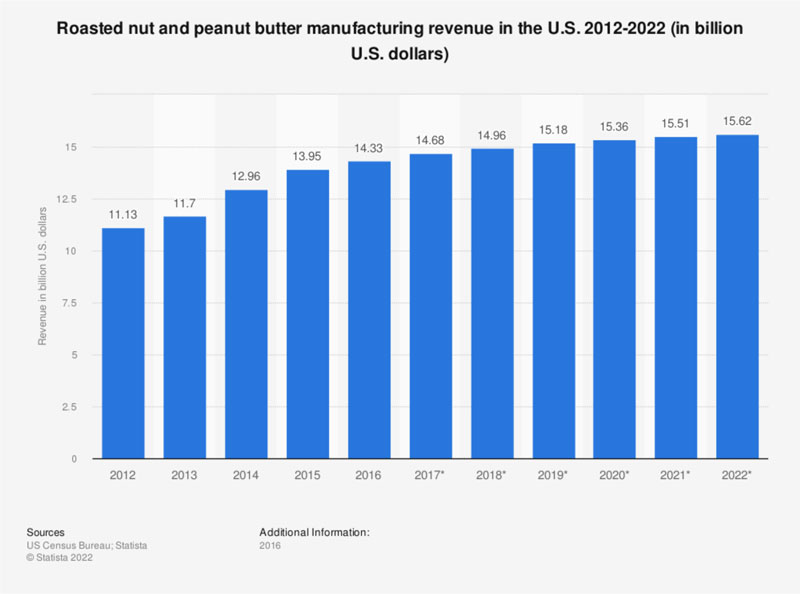

Just consider that the United States Nuts Market is projected to grow at an annual rate of 5% for the next five years. This growth in trend mirrors what has happened in the past 10 years. In fact, in the following text, you can check out the five findings that will prepare you for the nut-conveying process and boost your material handling. But before that, here is an example of the growth rate of roasted nut and peanut butter manufacturing in the past 10 years, so you can get a bigger picture.

Finding #1 – The Nut Industry Is Growing Every Year

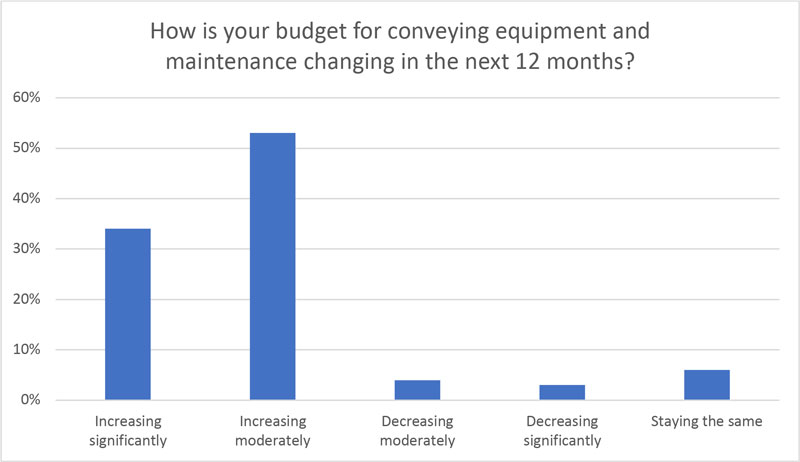

In the upcoming year, 87% of nut processing facilities will augment their budget dedicated to conveying equipment and maintenance. Notably, 34% of these facilities are indicating a substantial increase in the allocated budget, specifically aimed at addressing growth opportunities. Given the industry’s anticipated growth trajectory over the next 5+ years, proactive planning to accommodate this expansion is deemed essential for ensuring sustained success in the future.

What prompts the budgetary increase? It’s a direct response to the remarkable growth these businesses achieved in the preceding year. An impressive 71% of facilities witnessed a growth rate of 11% or more during this period. Given this substantial growth, it becomes imperative for facilities to strategize and prepare for heightened conveying capacity demands, aligning with the surge in overall market demand.

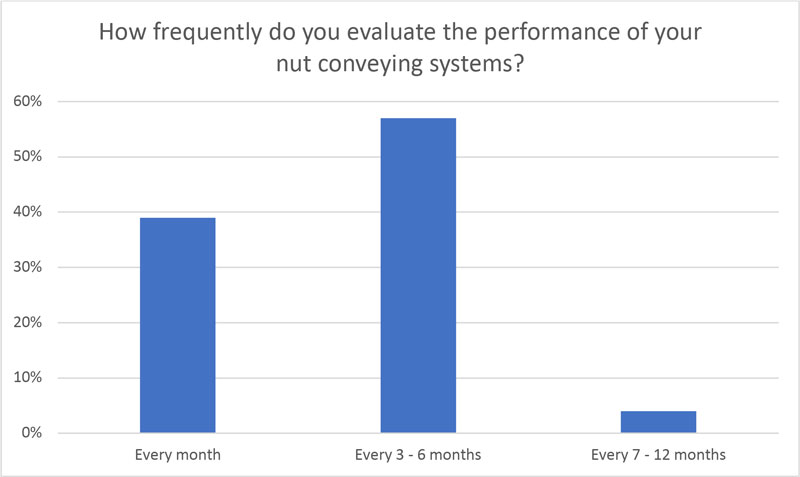

Finding #2 – Professionals Frequently Evaluate Their Conveyor Technologies

How often do professionals in the nut industry assess their nut manufacturing conveyor systems? We can affirmatively state that the answer is “sooner rather than later!” According to our survey, a substantial 96% of industry professionals conduct evaluations at least every six months, with 39% performing monthly assessments to ensure the continuous efficiency of their conveyor systems.

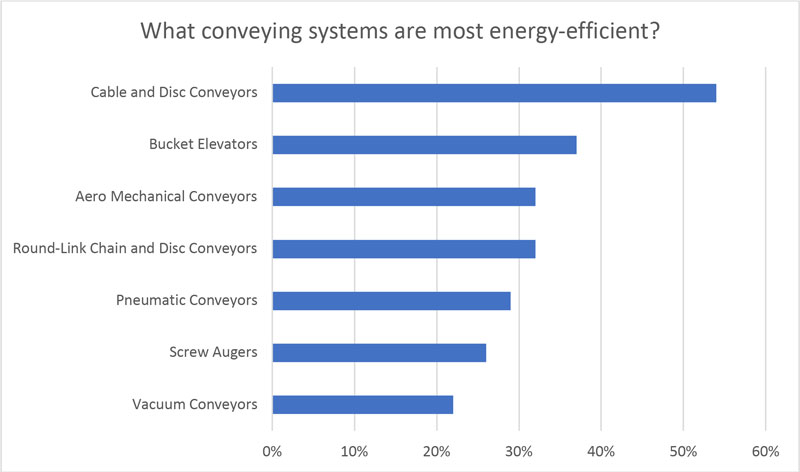

Finding #3 – Energy Efficiency Is a Big Deal

What factors contribute to energy efficiency? The dimensions of the motor and the horsepower necessary for operating an automated conveyor system can significantly influence production costs. When it comes to conveying nuts, which system stands out as the most energy-efficient? Cable and disc conveyors take the lead by a substantial margin, boasting a remarkable 54% efficiency compared to traditional conveyor solutions.

Consider the following queries concerning energy and efficiency: “What is the energy consumption of this system?” And “Is there a threshold, either high or low, beyond which the efficiency of this system diminishes?”

Finding #4 – Cable and Disk Conveyors Optimize a Facility’s Workspace

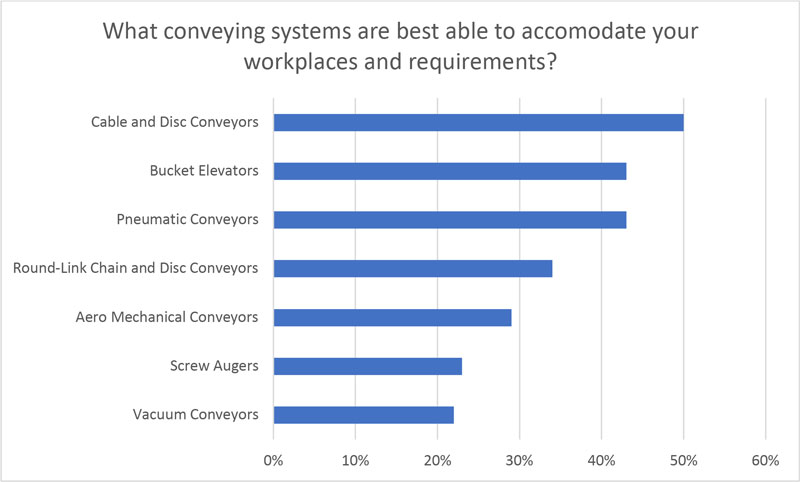

An essential aspect to contemplate during expansion is your workspace and facility needs. Which conveying systems align best with the available space? Are you making the most of the space at your disposal? Ninety-four percent of professionals in the nut industry have indicated their active efforts in optimizing workspaces and meeting facility requirements.

How do they achieve this optimization? As per insights from surveyed nut processing experts, the preferred conveying system (at 50%) for maximizing available space is cable and disk conveyors. In contrast, more traditional conveyor belt systems like bucket elevators (43%) and pneumatic conveyors (43%) take a more distant second place in the pursuit of optimizing workspace within a facility.

The fact is, you cannot have an automatic conveyor system without taking up some floor space. Depending on the size and layout of your facility, the amount of space you have to work with will be different.

Choosing the Right Conveyor Configuration – A Facility Layout Guide

When planning the layout of your facility, it is important to take into account all the specifics. Do you need multi-directional conveying? Multi-floor conveying? Do you have a lot of horizontal space or vertical space? Or both? What about any sharp turns or corners or potential existing equipment or barriers?

Your answers to these questions will help you determine the best conveyor type for your needs. It could be an overhead conveyor, a vertical conveyor, one that transports material at an angle, or similar. For example, if you need to move roasted or raw material between floors at a steep angle, a conveyor belt system would not be the best option.

A modular conveyor with all its components, such as a Cablevey tubular drag conveyor, is perfect for facilities with both ample and limited space. Conveyor systems manufacturers can configure them to fit almost any layout, and they can be modified in time as your facility grows or changes.

Explore a brief video demonstrating a nut-conveying system and techniques for space optimization, integrity maintenance, and quality preservation.

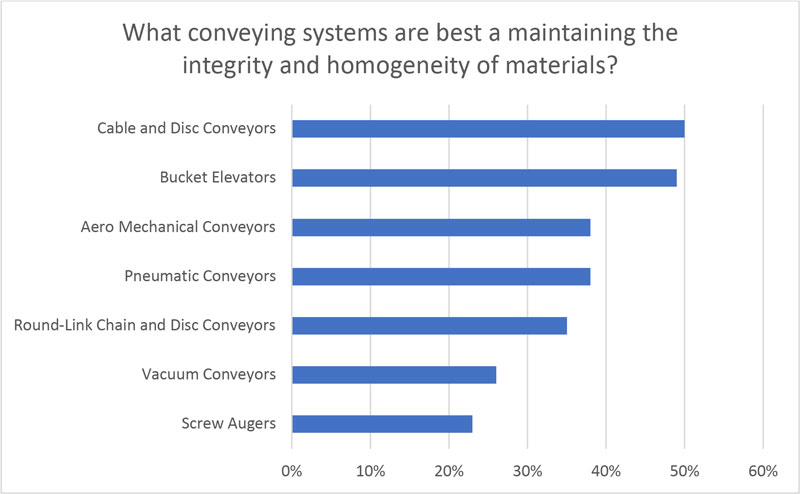

Finding #5 – Mixed Nuts and Gentle Conveying of Nuts

Delicate conveying is essential for the efficient and swift transportation of fragile products like nuts and nut-based items across various manufacturing stages, including sorting, roasting, chopping, and packaging. Ensuring the uniformity of nuts becomes particularly crucial, especially when conveying a mix of different nuts. In this regard, cable and disc conveyors secure the leading spot among industry professionals, garnering a 50% preference.

Cable and Disc Conveyors: A Superior Choice for Nut Processing

The research underscores cable and disc conveyors as the premier choice for nut processing facilities. Tubular conveying involves a coated, flexible stainless steel drag cable drawn in a looped system. Solid circular discs or flights affixed to the cable gently guide products through the system, aiding in sustaining the desired ratios of smaller and larger nut pieces. This mechanism also prevents the settling-out phenomenon that can occur with alternative conveyor technologies.

These discs facilitate the movement of the product through the tube without the use of air or excessive force, ensuring the preservation of material integrity and safeguarding the ingredients. The enclosed tubing significantly reduces dust, promoting a more sanitary and secure production facility while preventing product contamination. Opt for Cablevey tubular drag conveyors to minimize waste, prevent breakage, and attain the desired throughput in nut processing.

Optimal Maintenance and Cleaning for Cable and Disc Conveyors

What makes cable and disc conveyors widely favored? The Cablevey tubular drag-style conveyors are specifically crafted to necessitate straightforward pneumatic tensioning for cables, ensuring minimal maintenance requirements. Additionally, these conveyors facilitate easy cleaning through available clean-in-place methods, enhancing overall efficiencies and minimizing downtime.

What methods are employed to clean tubular conveyors? Wet cleaning, dry cleaning, and in-line cleaning options are accessible for Cablevey conveying equipment. The Cablevey engineering and service approach collaborates with nut processing teams to identify the most suitable cleaning solution tailored to specific needs and requirements.

For nut conveying, the enclosed tube environment keeps your materials free of contaminants and safe while in transit. Enclosed tubes can also be sanitized with minimal downtime when transitioning between products that have allergens.

Nuts Industry Trends for 2023 and Beyond – Cablevey Conveyor Engineering Guarantee Success

The nut industry is experiencing growth and transformation. This research study offers valuable insights into the details of how industry professionals are gearing up for this expansion and making optimal decisions for the enhancement of their facilities.

To find out if Cablevey’s tubular conveyor system is the best solution for conveying your nut products, have the Cablevey Testing Center perform a free test for you. The offer of free tests conducted under conveyor installation supervision by the Cablevey Testing Center is a testament to our commitment to providing tailored solutions. Contact us today, and we’ll help you make an informed decision.