In the food processing industry, one of the central factors in operational efficiency is the power consumption of conveyor systems used to transport large quantities of materials. With the growing concern over escalating energy prices, food processors are keenly exploring options to cut down on power usage during the transportation of materials within the facilities. Let’s dive deeper into the various conveyor systems available and understand their energy consumption patterns.

Why Consider the Right Conveyor

In the highly competitive and environmentally conscious landscape of the food processing industry, selecting the right conveyor system transcends mere functionality. The choice carries far-reaching implications on energy consumption, operational costs, and a company’s carbon footprint. Consequently, choosing a conveyor system wisely becomes an exercise of foresight, marrying technology with sustainability.

By prioritizing energy efficiency and optimal performance, businesses can foster not only economic prudence but also environmental responsibility, paving the way for a future where innovation meets sustainability. Thus, a well-informed decision in selecting conveyors stands as a pillar for sustainable growth and a greener future in the food processing industry.

Pneumatic Conveyor Systems – High Energy Consumption

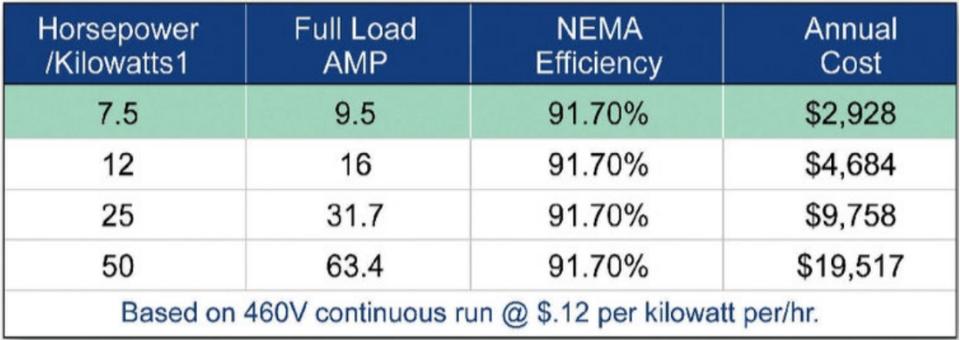

Pneumatic conveyors stand out as the most energy-consuming option among the different conveyor systems. These conveyors use air pressure, either above or below atmospheric levels, to move products at a high velocity through enclosed lines. Typically, pneumatic conveyors employ high-powered motors, ranging from 20 to 50 horsepower or even more, operating fans, blowers, and rotary valves. Due to their high-speed operation and the power required to maintain air pressure, they end up using a considerable amount of energy, often requiring ten times more power than some other types of conveyors.

A Conveyor Belt System and Bucket Elevator – The Middle Ground

Occupying the middle tier of energy consumption is the belt conveyor system and a bucket elevator. Belt conveyors operate through a closed-loop system where a belt is stretched across two or more pulleys, continually rotating thanks to a drive pulley. On the other hand, bucket elevators, as their name suggests, carry materials using buckets attached to a rotating chain or belt. These buckets pick up the material, move it to a designated point, discharge it, and then return to the starting point to collect a new load. For conveying similar volumes of material, these systems generally employ motors with an output of around 25 horsepower, providing a balance between efficiency and power consumption.

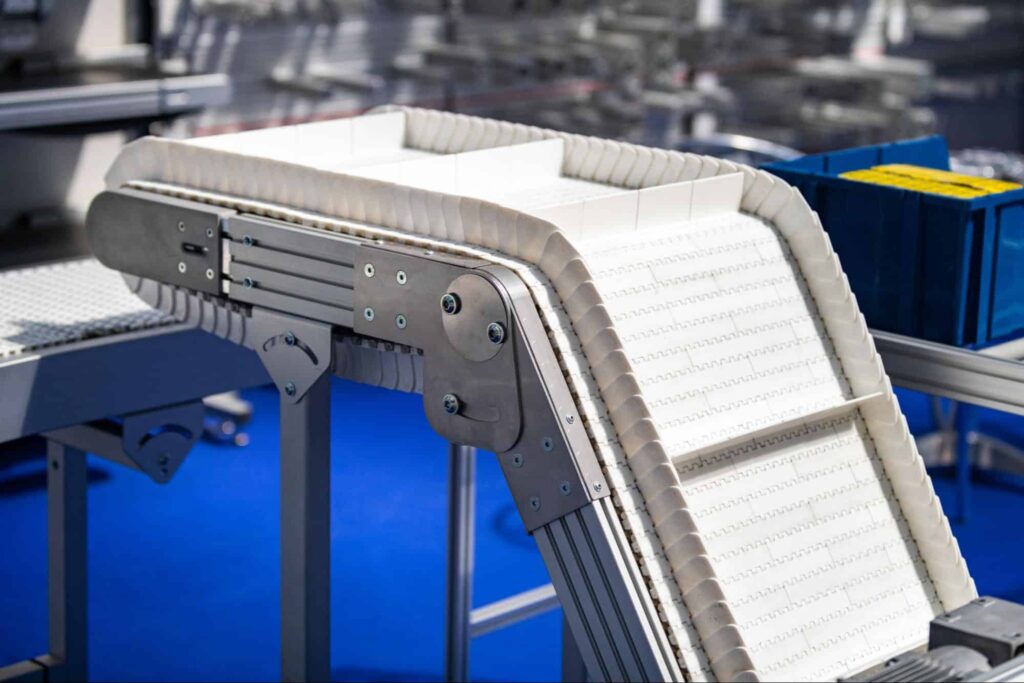

Tubular Drag Cable Conveyors – The Energy-Saving Choice

At the more energy-efficient end of the spectrum are the tubular drag cable conveyors, a particularly prudent choice for those looking to save on power consumption. These conveyors use a 7.5 horsepower motor, which is capable of bulk material handling as the other types mentioned. These conveyors work as bulk material handling equipment by dragging solid circular discs (or flights) attached to a cable at low speeds through a loop. This method requires significantly less energy, making it a cost-effective and environmentally friendly option.

According to Owen, an expert in the field, the substantial size, and number of discs on the 8-inch units enable them to convey amounts of material comparable to their belt, bucket, or pneumatic counterparts but with a substantial saving in energy consumption.

Power Consumption Resources and Future Perspectives

For those interested in delving deeper into the world of energy consumption, it is recommended to refer to valuable resources such as the Department of Energy’s publications, which offer comprehensive information on energy-saving strategies in industrial setups.

As we move forward, the focus should be on the continual development and innovation of conveyor systems, keeping energy efficiency at the forefront. Companies need to make informed decisions, not only based on the initial setup costs but also considering the long-term energy savings, which can have a significant impact on operational costs and environmental footprint.

Understanding the energy consumption patterns of different conveyor systems is critical in today’s world, where both economic and environmental factors play a key role. By opting for energy-efficient conveyor systems, food processing plants can significantly reduce their energy consumption, leading to a greener and more sustainable future.

This chart illustrates the remarkable energy efficiency of Cablevey Conveyors’ 5HP motor in comparison to chain conveyors, which consume 2.5 times more energy, and pneumatic conveyors, notorious for utilizing up to 10 times more power.

The Imperative of Wise Conveyor Selection

As the food processing industry grapples with rising energy prices and heightened environmental awareness, the focus sharpens on adopting efficient and sustainable practices. Choosing the right conveyor system emerges as a critical component on this path, influencing not only the bottom line but also the industry’s broader environmental footprint.

By opting for energy-efficient conveyors, companies can seize a golden opportunity to meld operational excellence with environmental stewardship. Understanding the nuances of various conveyor systems and making informed choices become not just a business strategy but a commitment to fostering a sustainable and prosperous future.

Harness the Future with Cablevey Conveyors

In light of these revelations, taking a step towards a sustainable and cost-effective operation is not just a possibility but a well-within-reach reality. Embrace the future of food processing with Cablevey Conveyors, a pioneer in offering energy-efficient conveyor solutions. Don’t just adapt – lead the way by making a conscious choice for innovation and responsibility. Contact Cablevey Conveyors today to explore the extensive range of energy-saving conveyor systems and take a vital step towards a greener, more prosperous future. Whether you need an industrial conveyor belt for your warehouse or a custom conveyor belt for food, make the choice that defines tomorrow today!