Discover Tube Conveyor Uses

What are you moving?

Welcome to the world of innovative conveyor solutions where tube conveyors reign supreme. Understanding the tube conveyor uses can revolutionize how you handle specialty materials. Dive deep into the advantages and versatility of the tubular conveying system and unveil the potential of efficient, safe, and cutting-edge material transport in a plethora of industries.

Cablevey Tube Conveyor Uses

Cablevey’s tubular conveyor systems have been globally recognized, transporting nearly a thousand different materials in 66 countries. Some of the world’s leading food processing corporations, both in the US and internationally, rely on our conveyor systems manufacturers. From coffee beans and morning cereals to oats and pet food, these major players in the industry have turned to Cablevey Conveyors for an automated conveyor system that ensures the safest and most efficient material movement.

Common Material Types

Disc and cable tubular conveyors are designed to transport specific materials that can be accommodated within a tube. However, the typical applications for this conveyor technology often fall within the following categories.

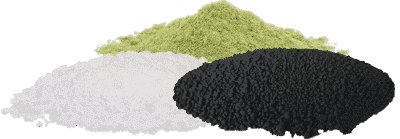

Small and Powdered Materials

Enclosed tube conveyors have emerged as a preferred choice for handling materials prone to being displaced by wind or external forces. By securely containing these materials within the tube, automated conveyor systems not only ensure their efficient transport but also significantly minimize wastage.

Clean Materials

Enclosed conveyor solutions offer a pristine solution for transporting food products, ensuring they remain uncontaminated throughout the process. Moreover, these sealed systems prevent the surrounding processing facility from being tainted by the materials, safeguarding both the integrity of the product and the cleanliness of the plant.

Toxic Materials

By securely enclosing materials within the tubes, these conveyor systems not only ensure the safe handling of potentially toxic substances but also prevent any cross-contamination in the production facility. This meticulous design is especially vital when dealing with hazardous or toxic materials, guaranteeing safety and cleanliness at every stage of the production process.

Delicate Materials

Cable and tube conveyors feature distinct “pockets” that facilitate the gentle transportation of substantial quantities of products. After materials are positioned between the discs inside the tube, they can be safely conveyed at speeds suitable for the specific product, covering extended distances without compromise.

Modular Component Design

To cater to the diverse requirements mentioned earlier, our cable and tube conveyor setups are modular in design, ensuring adaptability for a broad spectrum of uses. The constituent parts are available in multiple sizes, compatible with our tube dimensions, and tailored to your materials. Additionally, we provide an extensive selection of inlets, cleaning features, and transfer system elements.

Cablevey Conveyors Offer Custom Solutions

Every conveyor system we offer is meticulously tailored by our conveyor engineering department, ensuring each setup is perfectly aligned with client requirements. Key design factors often encompass the quantity of material that can be transported without damage, as well as the distance, elevation, and speed at which materials need to move.

The layout and space availability within processing setups are also factored into the design process. In essence, with our seasoned engineers and techniques for manufacturing conveyor systems, we’re equipped to address nearly all material transport challenges using cable, disc, and tube conveyors. For more information or a customized solution, please contact us.

Blends And Mixes

Coffee

Nuts

Snack Foods

Pet Food

Breakfast Cereal

Frozen Food

Specialty Seeds, Beans

Industrial Hemp

Breweries/Specialty Grains

Powders

Rice

General Food

Industrial Materials

Schedule a Product Test