Predictive maintenance technologies are revolutionizing the longevity and efficiency of tubular drag conveyor systems. By utilizing data analytics, machine learning, and real-time monitoring, these innovative conveyor solutions predict and identify potential failures before they occur. Consequently, predictive maintenance of tubular drag conveyor systems brings minimized downtime, reduced repair costs, and extended operational life of their systems. This ensures that material handling processes are consistently efficient, reliable, and cost-effective, leading to enhanced productivity and profitability.

Maintenance of a Tubular Drag Conveyor – What Does It Require?

Conveyance systems are critical to the efficient operations in many different fields of manufacturing. The biggest headaches of industrial conveyor systems are constant maintenance tasks and failures due to the buildup of material. A reliable tubular drag conveyor system needs two things: cleanliness and predictive maintenance technology.

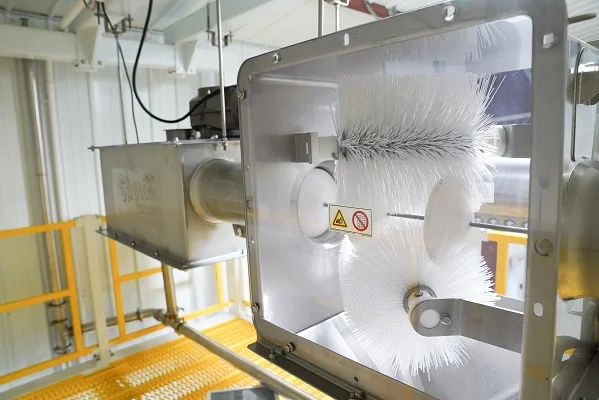

For easy cleaning and maintenance of a cable and disc tubular conveyor, a brush box is necessary. It has a simple housing that the cable and discs pass through. The housing contains unique roller brushes that remove particles and other debris that may cling to the discs and cable, thus increasing the system’s operating life.

Why Do We Need Predictive Maintenance Technologies for Conveyor Systems?

Predictive maintenance technologies like conveyor monitoring system cameras and other types of feedback sensors are used to determine the health and performance of the conveyor system. More precisely, these technologies are used to diagnose failure symptoms of the system’s internal components prior to complete loss of operation.

Cablevey Conveyors Offers Systems With Outstanding Predictive Maintenance Technologies

All customers want a system that’s easy to maintain, assemble, and disassemble – with technology that has an inherent ability to prevent failure and prolong wear. Cablevey Conveyors stand out among many conveyor manufacturers thanks to the efficiency and excellence of our systems. Our diagnostics tools will make your operations a breeze with their user-friendly interfaces.

The system inspection camera is designed to be a diagnostic tool that runs through your tubular conveying system after assembly to ensure the conveyor is installed correctly. The camera is equipped with a removable micro SD card and a self-contained LED lighting unit. The system inspection camera assembly is attached to the cable as two disc halves, each firmly gripping and moving with the cable. This camera allows technicians to diagnose issues within a few minutes – on-site or from a remote location – without disassembly of the conveyor.

Cablevey Conveyors has improved the convenience of cleaning their cable and disc tubular drag conveyors with the introduction of the side access brush box. The brush box is used to reduce material buildup on cables and discs. Let’s take a look at a few other cutting-edge features of our conveyor systems that you should know about:

- Dual side access – Two covers have been added to the side rather than the top of the brush box. They are removable and act as entrance points to the brush box.

- Low friction ultra high molecular weight (UHMW) bushing – This component is added to increase wearable surface by three times. It prolongs bearing life, resulting in less maintenance inside of the brush box.

- Disassembly/assembly efficiency – The time of disassembly and cleaning of internal components is greatly reduced as most brush boxes offer little to no visibility to ceiling-mounted components.

- Inspection accessibility – Side-mounted covers allow operators access to view internal parts working in the brush box and cable being pulled through. This is beneficial if there are no inspection tubes installed on the system.

Contact Cablevey Conveyors to Get a Quote for Our Stellar Conveyor Technologies

For exceptionally smooth cable conveyor installation, implement Cablevey’s cutting-edge conveyance technologies. Cablevey’s systems increase the efficiency of operations to utilize scarce resources on other issues. Less interaction with the equipment saves money by lowering maintenance time and labor costs. If you want to learn more about Cablevey’s predictive maintenance technologies and get a quote on how to optimize your existing system, contact us today. We would be happy to help you – let’s work together to improve your production operations.

FAQ

What Is Predictive Maintenance Technology in the Context of Tubular Drag Conveyor Systems?

Predictive maintenance technology for tubular drag conveyor systems employs data analytics, machine learning, and real-time monitoring to foresee potential failures. These technologies evaluate the health and performance of industrial conveyor systems, diagnosing issues before they escalate. This proactive approach minimizes downtime, reduces repair costs, and extends the operational life of conveyor systems, ensuring consistently efficient and reliable material handling processes.

How Does the Brush Box Contribute to the Maintenance of a Cable and Disc Tubular Drag Conveyor?

The brush box is instrumental for cleaning cable and disc tubular drag conveyors. As the cable and discs pass through the brush box, roller brushes within the housing remove debris and particles that may adhere to these components. This cleaning process not only ensures the system’s cleanliness but also contributes significantly to extending its operational life by preventing the buildup of materials that can lead to wear and tear.

Why Is the System Inspection Camera Important for the Maintenance of Conveyor Systems?

Cablevey’s system inspection camera is a diagnostic tool essential for assessing the internal condition of a tubular drag conveyor without disassembly. Equipped with a removable micro SD card and self-contained LED lighting, it provides quick, on-site, or remote diagnostics. This tool ensures the conveyor is installed correctly and helps technicians identify and address issues promptly, enhancing the system’s efficiency and longevity.

How Does Dual-Side Access Improve the Functionality of the Brush Box?

Dual-side access enhances the brush box’s functionality by offering operators easy entry points for maintenance and inspection. Unlike top-mounted covers, side access enables efficient disassembly, cleaning, and viewing of internal components working in real-time. This feature facilitates quick maintenance, ensuring that the conveyor system remains in optimal condition, leading to reduced downtime and increased operational efficiency.

What Role Does the Low Friction Ultra High Molecular Weight (UHMW) Bushing Play in the Maintenance of Conveyor Systems?

Low friction UHMW bushing in the brush box increases the wearable surface by three times, extending bearing life and reducing maintenance needs. It reduces friction, wear, and tear on the system, contributing to the enhanced durability and efficiency of the conveyor. With UHMW bushing, businesses experience decreased maintenance time and costs, leading to increased operational uptime and productivity.

How Do Cablevey’s Predictive Maintenance Technologies Optimize the Efficiency of Tubular Drag Conveyor Systems?

Cablevey’s predictive maintenance technologies, including the system inspection camera and Diagnostics Tools, allow for timely detection and resolution of potential issues. By ensuring correct installation and facilitating quick, efficient diagnostics, these technologies reduce downtime, maintenance time, and labor costs. The result is an optimized, highly efficient conveyor system that reliably supports enhanced productivity in material handling operations.

How Can Businesses Benefit From Implementing Cablevey’s Conveyor Systems With Predictive Maintenance Technologies?

Businesses adopting Cablevey’s conveyor systems equipped with predictive maintenance technologies gain a significant edge in operational efficiency. These technologies minimize unexpected breakdowns and the associated downtime and repair costs. Enhanced system longevity, reduced maintenance needs, and the ability to diagnose and resolve issues swiftly contribute to improved productivity, reliability, and cost-effectiveness in material handling and overall production operations.