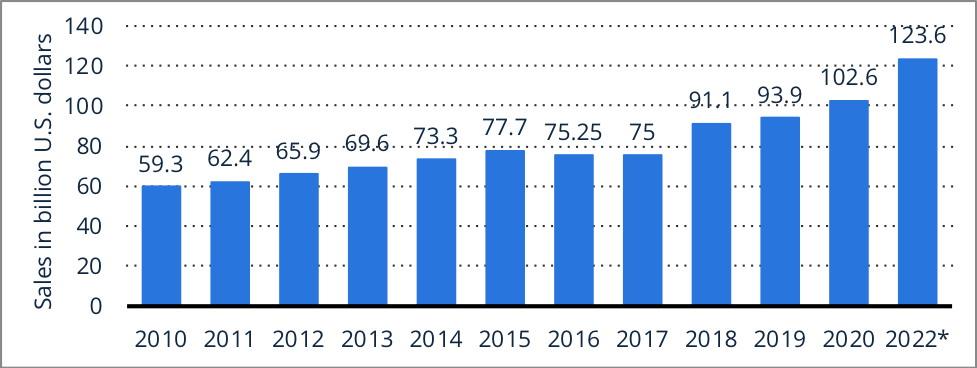

The pet food industry continues to grow, with worldwide sales in 2022 at $123 billion (in U.S. dollars) and the projections for 2023 are $147 billion, according to Statista. Here are the sales of pet food worldwide from 2010 – 2022.

Growth is a great opportunity, but it also requires planning when it comes to how pet foods are conveyed in your facility. How are companies preparing to handle this type of growth at their processing facilities?

In October 2022, Cablevey Conveyors commissioned the independent research firm, Ascend2, to conduct a research study titled Evaluating and Implementing New Conveyor Systems. The 16-page study (download for free) asked 290 food processing professionals in the United States and the United Kingdom to provide their insight on critical considerations when evaluating conveyor systems.

In this article, we will review and analyze the findings from 72 food processing professionals that are conveying pet food. What are they doing to prepare for growth?

Finding #1: Budgeting for Growth.

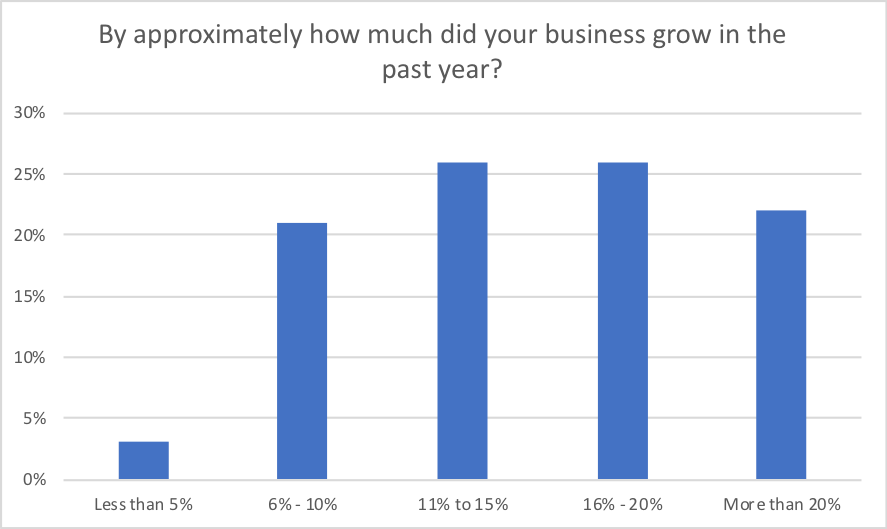

85% of facilities processing pet foods are increasing their budget for conveying equipment and maintenance in the next 12 months. 35% tell us that they are increasing significantly the budget needed to meet growth opportunities. Why the increase in the budget? The increase is in response to how much these businesses grew in the past year.

Finding #2: Can your workspaces facilitate needed growth?

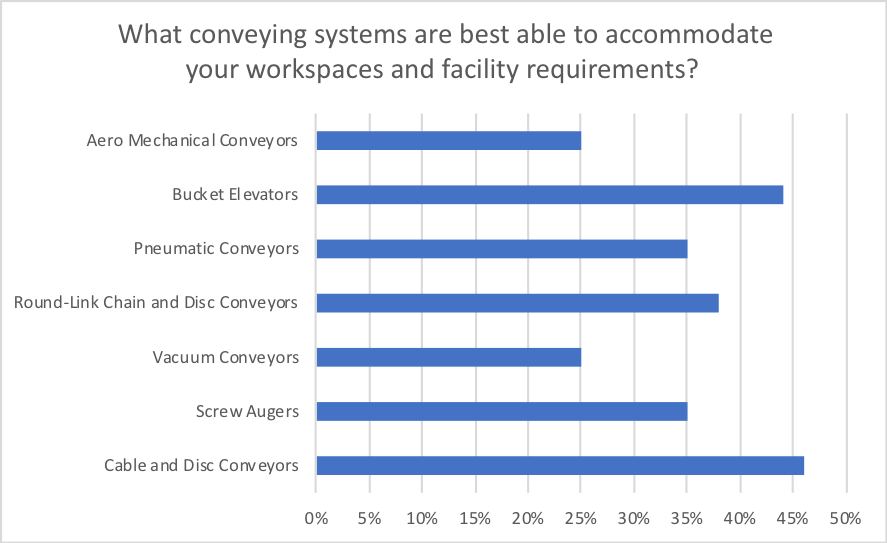

An important consideration of growth is your workspaces and facility requirements. What conveying systems are best for the space that you have available?

According to the pet food processing experts surveyed, the #1 conveying system (46%) for maximizing available space is cable and disk conveyors.

What are a few questions should you ask when evaluating the right conveyor system to optimize the space at your facility?

- Do you have enough floor space or ceiling height to accommodate certain conveyor types?

- Does the layout of the conveying system take into account easy access for cleaning and maintenance, worker safety, and operational performance?

Here is a short video that shows a pet food conveying layout.

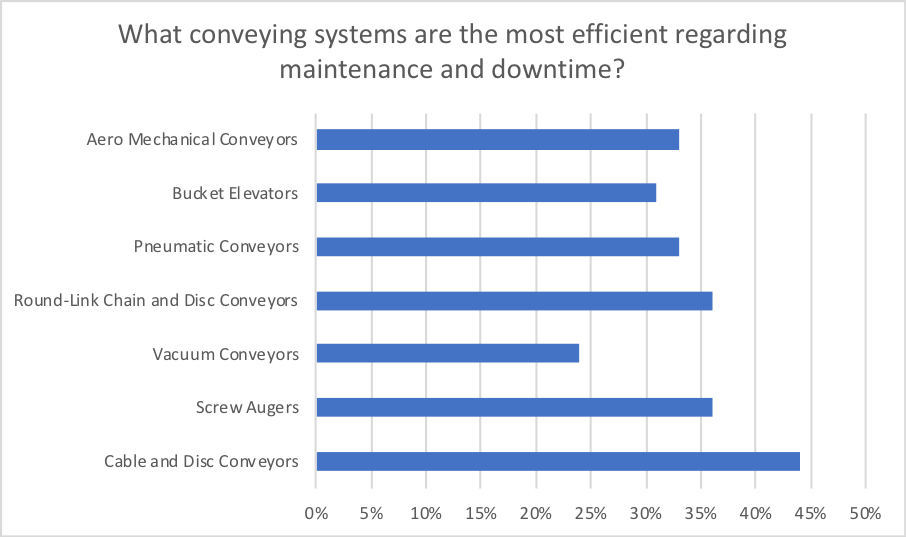

Finding #3: Consider maintenance and downtime when you plan.

For pet food, what conveying systems are the most efficient? Cable and disc conveyors lead the pack (by a wide margin) at 54%.

What are a few questions should you ask when evaluating the right conveyor system when it comes to maintenance and downtime? Questions to ask:

- How much time will be spent disassembling and cleaning the system?

- Will maintenance and downtime costs exceed any savings that you realized when purchasing the system?

Finding #4: Don’t forget energy efficiency.

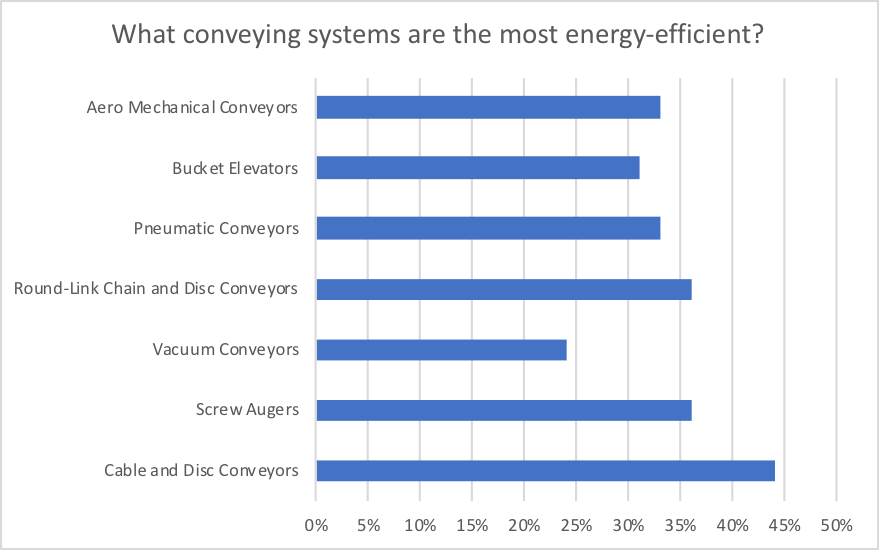

What contributes to energy efficiency? The size of the motor and the amount of horsepower required to run a conveying system can have a major impact on production costs. What conveying systems is the most energy efficient for pet foods? Cable and disc conveyors are #1 at 44%.

Here are two questions to ask regarding energy and efficiency:

- How much energy will this system use?

- Is there a high or a low cut-off point at which this system becomes inefficient?

Conclusion

The pet food industry is growing and evolving. This research study provides insight into the specifics of how industry professionals are preparing for that growth and making the best decisions for their facilities.

The research points to cable and disc conveyors as the superior solution for pet foods. Tubular conveyors help streamline pet food processing and maintain both quality and proper proportions in nutritional mixes, snack foods, and other pet food products, product characteristics important to pet food purchasers. To find out if a Cablevey system is the best solution for conveying your pet food, have the Cablevey Testing Center perform a free test for you. The Testing Center will provide you with the data to help you make the most informed decision for your specific need.

This article only covers a portion of the finding from the Ascend2 research study. Download Evaluating and Implementing New Conveyor Systems for more insight into the food processing industry.