Leading the Industry in Gentle Conveyance

Rely on the established leader in the food processing industry for gentle, reliable conveyance of materials. Cablevey Conveyors offers enclosed, tubular drag conveyor systems that are found in over 65 countries and used to transport more than 1,000 different types of materials.

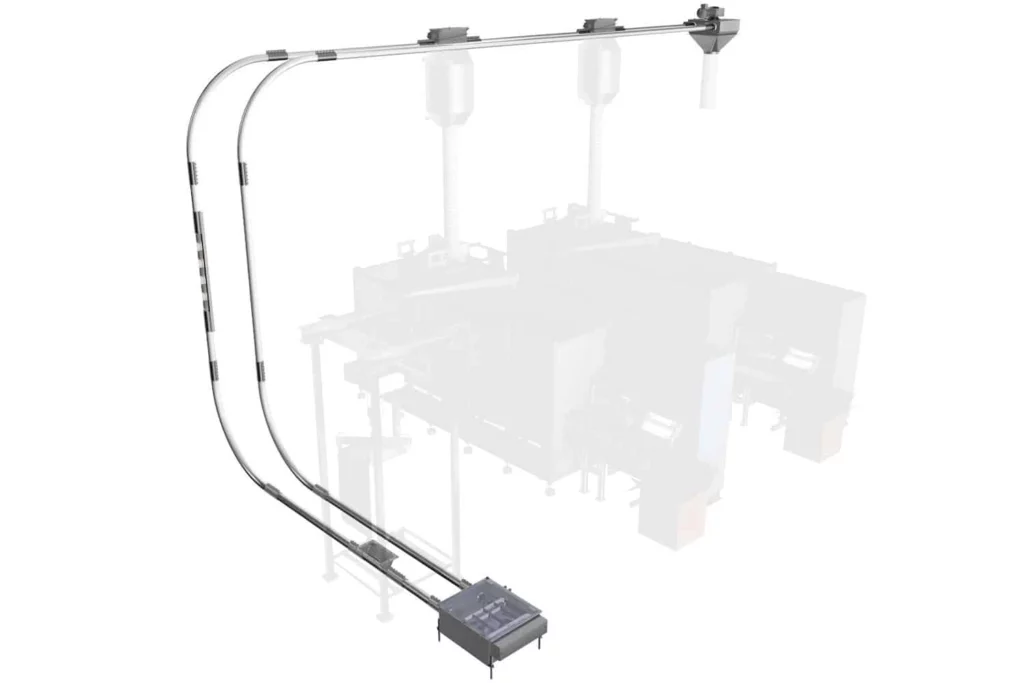

Our modular system relies on basic components such as discs, tubing, cables, and sweeps that supply the flexibility and adaptability to accommodate a processing plant’s space and specifications. This flexibility easily enables customization – you can move materials in any direction, horizontally or vertically, from floor to mezzanine or between buildings, with minimal modifications to your facility.

From powders to pet food, coffee, and cocoa to cereals or snacks, Cablevey Conveyors provides unique benefits that help widen profit margins. Let us help you drastically minimize product breakage and conserve energy with disc and cable tubular conveyors from Cablevey Conveyors!

- Conveyor Layouts

- Frequently Asked Questions

- From the Blog

System Features and Benefits

Easy To Clean

Wet and dry in-tube cleaning options reduce the time between changeovers and preserve resources. Clean-in-place methods are also available to improve efficiency and reduce downtime.

Enclosed, Sanitary and Dust Free Environment

Enclosed tube conveyors improve plant safety and hygiene by drastically reducing the amount of dust while protecting against product contamination.

Operates on Multiple Planes

A tubular conveyor can be designed with layouts to fit any configuration or elevation, with multiple inlets and discharges.

Low Impact Installation

The modular design provides tubular drag conveyors with immense flexibility and versatility for conveyor installation or upgrades as needed. The system fits within floor space limitations, up (ascending) and down (descending) inclines or around corners (sweeps at 45, 60, and 90-degree angles).

Low Maintenance

Tubular drag conveyors are designed to require simple pneumatic tensioning for the cables, and they require very little maintenance.

Blend Integrity

A disc system mounted on the cable keeps contents secure from inlet to discharge. It safeguards pre-blended mixes of varying bulk densities to eliminate sifting or product loss.

Quiet and Energy Efficient

The engineered design requires lower horsepower motors. It has lower energy requirements, and its operations are quiet.

Size and Capacity Matter. We Have a System that Works.

8” Diameter Tube Conveyor Systems

Our newest introduction for tube diameters, the 8-inch system is designed to carry large volume of nuts, whole walnuts, pet foods, breakfast cereals and other materials.

- Conveys up to 2,000 Ft3 (56.6 M3)/hour or 80,000 lbs* (Kgs)

- High-volume capacity

- Easy maintenance

*Lbs. per hour calculation depends on bulk density of the materials

Cable Speed

ft (m) / minute

40 (12)

60 (18)

80 (24)

100 (30)

120 (36)

140 (43)

Flow Rate

ft3 (m3) / hour

571 (16)

857 (24)

1,143 (32)

1,429 (40)

1,714 (48)

2,000 (54)

/

lbs (kg) / hour

22,840 (10,360)

34,280 (15,549)

45,720 (20,738)

57,160 (25,927)

68,560 (31,098)

80,000 (36,287)

6” Diameter Tube Conveyor Systems

Offers high volume conveyance of specialty materials, foods and ingredients and movement from one plane to another, such as floor to mezzanine or an adjacent building.

- Handling capacity of up to 1,240 Ft3 (35.4 M3)/hour or 49,429 lbs. (22,420 Kgs)*

- Variety of cleaning methods available

- Enclosed dust-free environment

*Lbs. per hour calculation depends on bulk density of the materials

Cable Speed

ft (m) / minute

40 (12)

60 (18)

80 (24)

100 (30)

120 (37)

140 (43)

Flow Rate

ft3 (m3) / hour

350 (10)

503 (15)

710 (20)

880 (25)

1,060 (30)

1,240 (35)

/

lbs (kg) / hour

14,120 (6,400)

21,180 (9,610)

28,240 (12,810)

35,300 (16,010)

42,360 (19,210)

49,420 (22,420)

4” Diameter Tube Conveyor Systems

Our most popular size conveyor system, dubbed the “workhorse,” the 4-inch system gently conveys whole bean roasted coffee, raw peanuts, seeds and grains.

- Conveys up to 525 Ft3 (14.87 M3)/hour

- Gentle material handling

- Easy to clean and maintain

*Lbs. per hour calculation depends on bulk density of the materials

Cable Speed

ft (m) / minute

40 (12.19)

60 (18.29)

80 (24.38)

100 (30.48)

120 (36.57)

140 (43)

Flow Rate

ft3 (m3) / hour

150 (4.25)

225 (6.37)

300 (8.5)

375 (10.62)

450 (12.74)

525 (14.87)

/

lbs (kg) / hour

6,000 (2,722)

9,000 (4,082)

12,000 (5,442)

15,000 (6,803)

18,000 (8,163)

21,000 (9,524)

2” Diameter Tube Conveyor Systems

The smallest diameter for our conveyor systems, the 2-inch system was originally designed to move mash and grain mixes, now commonly used for reclaimed materials including coffee chaff, cookie crumbs, seeds and ground coffee.

- Conveys up to 75 Ft3 (2.12 M3)/hour (3,000 Lbs)

- Customizable to fit your specifications

- Quality construction and engineering

*Lbs. per hour calculation depends on bulk density of the materials

Cable Speed

ft (m) / minute

40 (12.19)

60 (18.29)

80 (24.38)

100 (30.48)

Flow Rate

ft3 (m3) / hour

30 (.85)

45 (1.27)

60 (1.70)

75 (2.12)

/

lbs (kg) / hour

1,200 (544)

1,800 (816)

2,400 (1,088)

3,000 (1,361)

Let's Get Started

Modular Components Allow for Flexbility and Easy System Integration

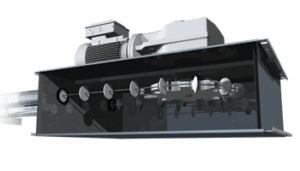

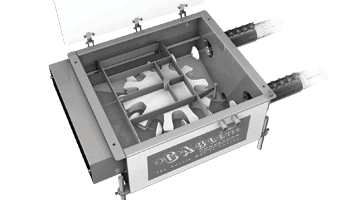

DRIVE UNIT

The cable is pulled through the drive unit by an electric gear motor

mounted to a stainless steel frame. The cable can enter and exit through

either tube port as required for your layout.

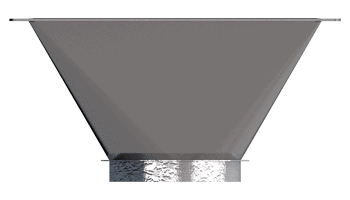

Funnels are used to discharge material from rotary discharges and/or cleanouts.

Funnel outlets are available in a wide variety of sizes and connection types to fit your needs.

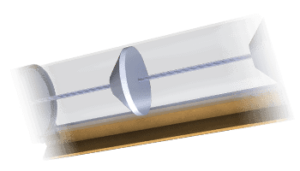

The Inspection Section is a food grade plastic tube that

allows you to see the product conveyed and observe the cleaning process.

These sections can be installed in the vertical or horizontal runs as desired.

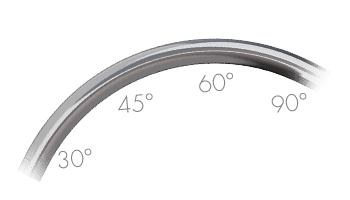

Sweeps change travel to any desired direction. Sweeps are available in many

angles from 0-90 degrees and in several different

radius dimensions (45, 60, & 90 degrees) to fit restricted spaces.

The coupler’s food grade rubber gasket ensures

a good seal against air, water and dust. The coupler holds the tubes

together in perfect alignment to provide the discs a smooth path.

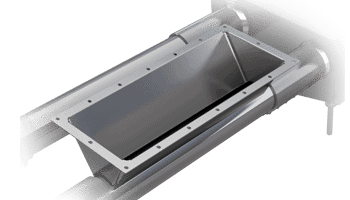

Inlets are available in a wide variety of lengths to accommodate various needs.

The sides of the inlets are available in different slopes to accommodate

different material flow properties. Multiple inlets may be used if desired.

The turnaround contains a sprocket that facilitates reversing

cable direction from the return side of the system to the product conveying side.

The sprocket is mounted on a mechanism designed to provide proper cable tension.

The discharge has the ability to be open or closed allowing

materials either to pass through or exit the conveyor at that point.

A Brush Box is a housing that the cable and discs pass through.

The Brush Box contains two roller brushes mounted above and below the cable and discs.

As the cable moves through the discs turn the brushes removing any clinging

particles into a waste chute for disposal. This mechanical process

operates without additional power requirements.

Flexible Tubular Conveyor Layouts and Design

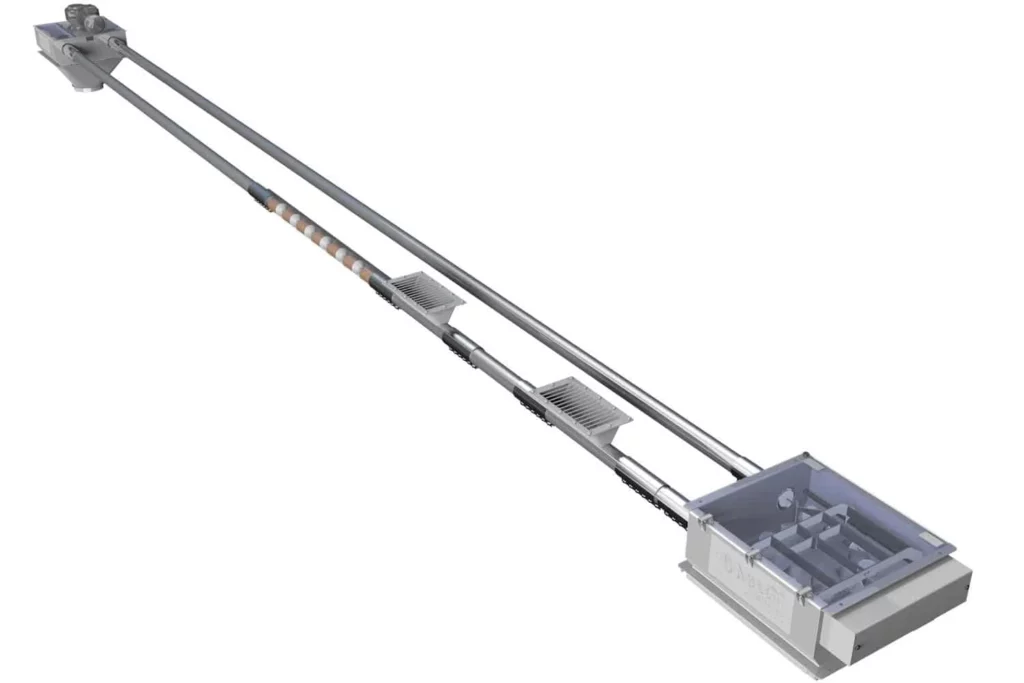

HVH

HVH layouts carry materials from point to point and at varying altitudes.

Horizontal Corner

Horizontal corner layouts, typically 90, 75, or 60 degrees, can be customized to a 24″, 36″, 48″, and 60″ radius.

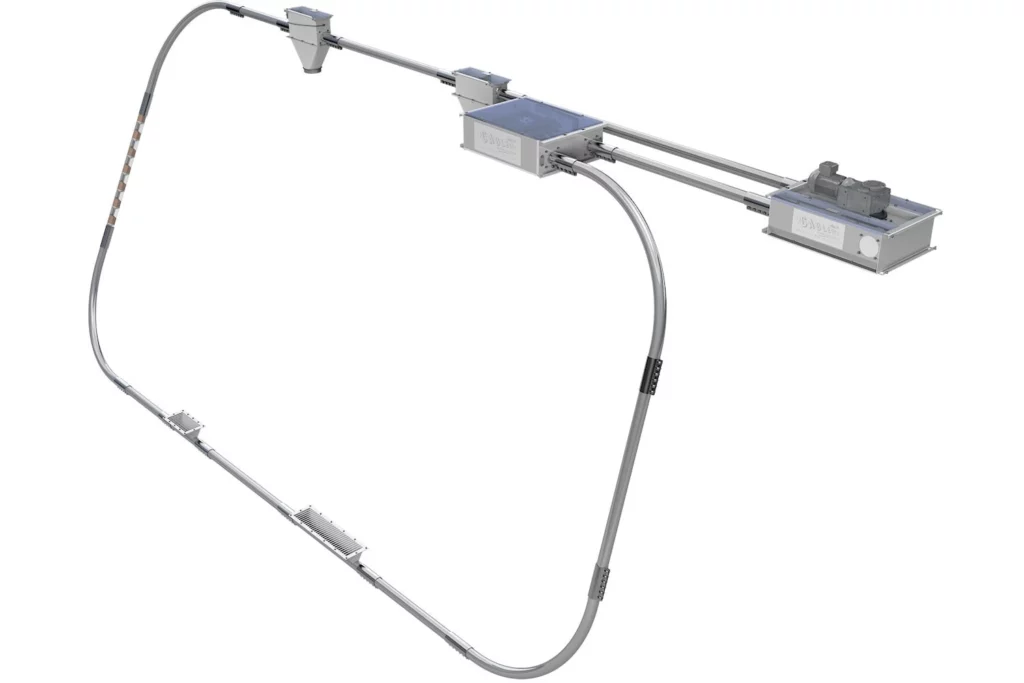

Loop

Loop layouts move materials in a tight or pre-defined space and allow for multiple inlets.

Inline

Inline layouts are the simplest installations for point-to-point conveyance.

Horizontal Transfer

Horizontal transfer layouts allow for long runs and can accommodate multiple inlets.

Horizontal-Vertical Horizontal 3D

Horizontal-Vertical-Horizontal layouts carry materials from point-to-point and at varying altitudes.

U-Shape

U-Shape layouts move materials in tight or pre-defined spaces and allow for multiple inlets.

Vertical Transfer

Vertical transfer layouts are often used to move materials to and from mezzanines. Vertical transfers also commonly blend ingredients via multiple inlets.

Customize a Layout for Your Facility. Call Cablevey Today.

At Cablevey Conveyors, we understand that every facility has its unique challenges and requirements. That’s why we specialize in creating customized conveyor layouts tailored to your specific needs. Our team of experts is dedicated to designing a system that fits seamlessly into your existing space, maximizing efficiency while minimizing disruption. Whatever material you’re handling, our tubular conveyor systems will be engineered to meet your demands.

With our advanced conveyor technologies and innovative designs, we ensure gentle handling, contamination prevention, and energy efficiency. Don’t settle for a one-size-fits-all solution. Contact us today to discuss how we can design the perfect conveyor solutions that elevate your facility’s operations. Remember, the best conveying solutions are just a conversation away.

We Move Leading Brands Forward

Frequently Asked Questions

With Cable and Tubular Drag Conveyors, How Far Can Materials Be Moved?

We have conveyed materials up to 300 ft (91m). However, the maximum conveying distance is ultimately determined by the type of product to be conveyed, the capacity required, and the number of sweeps (directional changes) needed for the intended configuration.

What Kind of Products Do You Move?

Cablevey Conveyors tube conveyor installation spans the globe to convey over 1,000 types of materials moved in over 65 countries. Our equipment services many of the largest food processing companies both in the United States and abroad.

Are Cable Conveyors Custom-Configured for Every Facility?

Yes, they are. We always include custom conveyor engineering in our quotes as production processes, facility size, and configurations are highly variable. We pride ourselves in being sticklers about efficiency, savings, and safety.

What Tube Size Is Right for My Operation?

We offer a range of tube diameters from two to eight inches. Recommended tube sizes vary by particle size and capacity requirements. Our engineers will design a system customized to your needs.

How Do You Clean the Conveyor?

Each facility develops its own cleaning protocols based on the sanitation regulations and the challenges of its products. There are different methods offered to clean and sanitize your Cablevey conveyor depending on the material being moved. Our systems can accommodate a range of cleaning options, including wet, dry, and clean-in-place types of cleanings.

From The Blog

Cablevey Perform Factory Acceptance Test at UK Test Facility

Learn how our new UK facility conducted its first factory acceptance test for conveying powdered material discharged from bulk bags.

Cablevey Conveyors celebrates the opening of new UK manufacturing facility

Cablevey celebrates the opening of its new UK facility, with guided tours and demonstrations.

Cablevey Discuss Solutions & Challenges at SNACKEX 2024

How Cablevey Conveyors showcased snack handling solutions at SNACKEX 2024 in Stockholm.