Tubular drag conveyors offer a myriad of benefits, but when it comes to uptime and less material breakage, certain types of conveying solutions are better than others. That’s why the debate of chain vs. cable disc conveyors is pivotal. By delving into the intricate differences and unique advantages of each option, businesses can choose the most suitable conveyor system for their specific applications and operational demands.

Chain vs. Cable Disc Conveyors – Which One Would Win?

In today’s fast-paced manufacturing and processing industries, efficiency is everything. Time is money, and any disruptions to production can have a significant impact on the bottom line. That’s why maximizing uptime and minimizing breakage are critical objectives for any business that relies on conveyor systems. Two popular types of conveyors that have proven to be reliable and effective are the chain and cable disc conveyors. But which one is right for your business?

In order to understand this, we’ll take a closer look at the features and benefits of each conveying solution, as well as the factors you should consider when evaluating which one is best suited for your specific needs. Whether you’re looking to upgrade or replace your existing conveyor technologies or exploring options for a new facility and new conveyor engineering, this guide will provide you with valuable insights to help you make an informed decision.

What Are Chain Disc Conveyors?

Chain disc conveyors are mechanically driven conveyors that drag materials along the inside of a tube. The system consists of a chain with close-running discs spaced along its length, forming an endless loop that is pulled by a motor-driven sprocket within an enclosed tube. The system is designed to transfer flowable bulk materials from in-feed points to discharge points through an enclosed conduit.

While chain disc conveyors are a popular choice in many industries, they have some limitations when it comes to maintenance and material handling. As chains experience friction at points of direct contact, wear and tear can take place at those points along the entire length of the chain. To prevent excessive wear and keep the system properly aligned, the chain-drive components must be frequently adjusted. In order to maintain the appropriate chain tension, a tension turnaround unit is employed.

What Can You Expect From Cablevey Disc Conveyors?

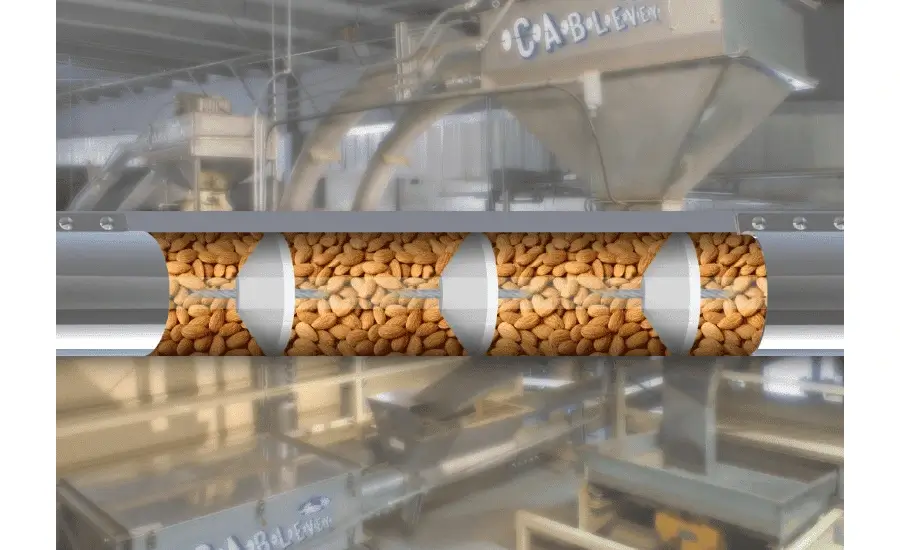

Cablevey disc conveyors operate similarly to chain disc conveyors but use a coated, flexible stainless steel drag cable instead of a chain. The cable is fitted with solid circular discs that push the food through the tube. This system has the capability to convey up to 80,000 pounds of product per hour at low speed and significantly reduce product degradation.

Cablevey disc conveyor solutions employ energy-efficient variable-speed motors ranging from 1 to 5 HP each, which ensures low power consumption compared to other conveyor systems used in food processing. Moreover, the system’s production flow can be adjusted to variable speeds, allowing for modifications in throughput as needed. The cable and disc assembly is powered by a drive unit and transported through the conveying tubes. The entire system is fully enclosed and dust-free, thanks to the use of compression couplers and gaskets that connect the various components together.

Why Cablevey Disc Conveyors Are Better Than Chain Disc Conveyors When It Comes to Decreased System Downtime?

One of the main advantages of Cablevey’s cable disc conveyors over regular chain disc conveyors is their reduced system downtime. Chain systems require more frequent maintenance, especially when it comes to adjusting the chain tension and replacing the sprockets. Any misalignment or wear and tear can cause the chain to jump off the sprocket or even break, which can cause significant downtime and require costly repairs.

Simplicity in Design – Cablevey’s Disc Conveyors Have Less Components That Can Fail or Need Replacement

In contrast to chain solutions, Cablevey’s industrial conveyor systems require less maintenance and are less prone to system failure due to their more flexible and durable design. In most tubular drag conveyors, including those produced by Cablevey Conveyors, the cable used is a WSC (wire strand core), also known as aircraft cable. The core is typically made of type 316 stainless steel, surrounded by stainless steel stranded ropes that consist of multiple steel strands arranged helically in one or more layers around the core.

Although there may be some wear and tear on the individual wires and strands due to friction, this also helps to compensate for minor failures in the short run. Thanks to this simpler yet durable design, Cablevey disc conveyors have fewer moving parts compared to chain systems, which means there are fewer components that can fail or need replacement. This simplicity also means that Cablevey’s systems can be easier to install and integrate into existing production lines, which can further reduce downtime and maintenance costs.

Why Cablevey Disc Conveyors Are Better Than Chain Disc Conveyors When It Comes to Material Breakage?

Another significant advantage of Cablevey’s disc conveyors over chain disc conveyors is their ability to reduce material breakage during conveying. Flexible stainless-steel cables with solid circular discs attached to them gently and smoothly move the product through the tube without causing damage or breakage. This flexibility enables seamless integration with various food production processes, ranging from raw material reception to weighing, filling, grinding, and packaging.

Chain Systems Often Cause Breakage During Conveying

In contrast to Cablevey’s conveyor technologies, chain systems use a chain with solid circular discs attached to it, which can cause friction and abrasion that can damage or break the product during conveying. This makes a chain system a less-than-ideal solution for applications where food components are fragile materials, contamination is a concern, or dust accumulation is a problem. Examples include filling and packaging operations.

Material breakage is an incredibly important factor in food processing applications, especially where product integrity and quality are crucial. By reducing material breakage and damage, Cablevey Conveyors can help maintain the quality and appearance of the product. This will increase customer satisfaction and reduce waste.

Contact Cablevey Conveyors to Get the Best Conveyor Technologies on the Market

When considering which tubular conveying system to use, it is important to take into account the specific needs and requirements of your production line. However, if minimizing downtime and material breakage are top priorities, then Cablevey’s conveyors are a clear choice. Our tubular cable and disc systems are a top-quality conveying solution for food processing facilities. Contact us to learn more about how we can help you choose the best type of tubular conveyor system for your facility.

FAQ

What Are the Core Differences Between Chain Disc and Cable Disc Conveyors?

Chain disc conveyors utilize a chain with discs that move materials inside a tube, requiring regular maintenance due to wear and tear from friction. Cable disc conveyors, on the other hand, use a flexible stainless steel cable fitted with discs, offering reduced maintenance, system downtime, and material breakage. They are energy-efficient, fully enclosed, and adaptable to variable speeds, ensuring product quality and operational efficiency.

How Do Cable Disc Conveyors Minimize System Downtime?

Cable disc conveyors excel in minimizing downtime due to their simple, durable design featuring fewer moving parts, reducing the likelihood of failures and maintenance needs. Unlike chain disc conveyors, which require frequent adjustments and replacements, cable disc systems are less prone to wear and tear. Their flexible cables and disc assembly ensure a smooth, efficient operation, enhancing productivity and reducing maintenance costs.

Are Cable Disc Conveyors More Energy-Efficient Than Chain Disc Conveyors?

Yes, Cablevey’s cable disc conveyors are designed for energy efficiency. They utilize variable-speed motors ranging from 1 to 5 HP, ensuring low power consumption. The system’s adjustable production flow and speed options offer flexibility to meet various throughput needs. In contrast, chain disc conveyors may not provide the same level of energy efficiency and adaptability, making cable disc conveyors a more eco-friendly and cost-effective option.

How Do Cable Disc Conveyors Reduce Material Breakage?

Cable disc conveyors are superior in preserving material integrity. The flexible stainless steel cables with attached discs ensure gentle movement of products through the tube, reducing breakage. In contrast, chain disc conveyors can cause friction and abrasion, leading to product damage. The design of cable disc conveyors is especially beneficial for fragile materials and applications where product quality and appearance are paramount.

How Do I Know if a Cable Disc Conveyor Is Right for My Business?

Consider your specific operational needs, including minimizing downtime and material breakage. Cable disc conveyors are ideal for businesses prioritizing these factors, offering reduced maintenance, enhanced product quality, and energy efficiency. Assess your production line’s requirements and consult with a conveyor system expert.