In the dynamic landscape of pet food manufacturing, the quest for optimal efficiency and cost-effectiveness has led industry leaders to innovative solutions. Explore a successful pet food conveyor story and how Cablevey’s automated conveyor system revolutionized C&D Foods’ processing line, offering a clean, gentle, and cost-effective solution.

Pet Food Conveyor Story – Embracing Tubular Conveyor Innovation

In the heart of pet food manufacturing at C&D Foods in Driffield, East Yorkshire, UK, a groundbreaking shift took place as the company embraced a cutting-edge solution to amplify its production capabilities. At the beginning of 2010, the company designed a new processing line to increase dog and cat food production.

However, since the company wanted to keep operating and maintenance costs low, it didn’t want to install screw conveyors or bucket elevators (the ones that are used in its other processing lines to transfer products between process steps). To find cost-effective, clean, and gentle conveyor solutions for the new line, the company worked with local conveyor systems manufacturers representative for a US-based equipment supplier.

Considering Different Conveyor Technologies

The company’s new processing line dries, mixes, and cools the pet foods at up to six tonnes per hour, more than 2.5 tonnes per hour than the other lines. When the company was searching for equipment for the line, it easily found a dryer, mixer, and cooler. However, it had difficulty finding a way to transfer the product between equipment at the required rate without using screw conveyors or bucket elevators.

“Traditionally, we would have used screw conveyors and bucket elevators to move the products,” says Jim Greenley, C&D Foods engineering and environmental manager. “However, to handle the increased production capacity, this equipment would have been fairly large, and the motors would have consumed a lot of power and kept operation costs high. Large bucket elevators have a lot of moving parts and swinging buckets that wear, which can cause spillage that can’t be recycled back into the system. Plus, screw conveyors and bucket elevators have a lot of maintenance requirements.”

Finding a Better Automatic Conveyor System

During the project’s planning stage, Greenley was contacted by manufacturers’ representative Steve Lovell, a sales manager for Flo-Mech Ltd., Orton Goldhay, Cambridgeshire, UK. Lovell proposed that they should use the equipment manufactured by Cablevey Conveyors, Oskaloosa, IA, USA, to move the products through the new line.

Cablevey’s industrial conveyor systems are a top-notch solution for agriculture, wood, food processing, and other bulk solids industries. Enclosed tubular drag cable conveyors, in fact, are the most used model for many companies that want a safe and efficient manufacturing process.

Overcoming Skepticism – Tubular Manufacturing Conveyor Systems Are Revelation at the Food Expo

“At first, we said no because we thought that it was an aero mechanical conveyor, which was something we didn’t want to use,” says Greenley. “Steve told us that it wasn’t. He said that it’s a slow-running, dust-free conveyor that can gently convey fragile products. He showed us a video of the conveyor operating.

We liked what we saw, so we sent the supplier some products and arranged to meet them at their booth at a food expo in Germany for a demonstration.” At the expo, the supplier put about 30 kilograms of dry dog food in a 2- 2-inch-diameter (5-centimeter-diameter) tubular drag cable conveyor and started it up. “For the next day and a half, I watched the conveyor move the dog kibble around, hour after hour,” says Greenley.

“When the trial run concluded, I saw very little breakage with just a little dust inside the tubes, and the dog kibble was still a good, salable product. This confirmed my interest in the conveyor engineering solution, and I got quotes for three of them. For our capacity requirement, they specified conveyors with six-inch-diameter (fifteen-centimeter-diameter) tubes because we’d get extra life out of them since they run slower than a smaller diameter conveyor.”

Advantages of the Tubular Drag Cable Conveyor System

In spring 2010, Greenley purchased three custom-designed Super 6 HVHstyle tubular drag cable conveyors, each with one inlet and one outlet. A local engineering contractor installed the processing line’s equipment, and a Flo-Mech engineer oversaw the final installation of the conveyors. In July 2010, the company commissioned and started up the new line. It processed the product at the required rate that very same day.

Unlike the traditional conveyor belt systems, each conveyor comprises dual enclosed tube sections, featuring an infeed and a return tube, accompanied by a turnaround section at one extremity and a robust 5.4-horsepower (4-kilowatt) drive-and-sprocket assembly at the opposite end. The turnaround segment adeptly links the infeed and return tubes at the infeed extremity, serving as an automatic tensioning device.

Meanwhile, the drive-and-sprocket assembly seamlessly connects the tubes at the discharge end, creating a continuous circuit. Crafted from stainless steel, the conveyor is meticulously engineered for food-grade applications, ensuring optimal suitability and compliance with industry standards.

Precision in Motion – Innovative Components Driving Conveying Excellence

Inside the enclosed tubes, a continuous and flexible stainless steel cable is meticulously installed, featuring mounted solid white plastic circular discs at regular intervals. These discs, designed with a focus on facilitating smooth material movement and reducing degradation, play a crucial role in the conveying process. With their dimensions closely mirroring those of the tubes, the discs maintain a narrow clearance with the tube walls, ensuring that the conveyed material remains confined between them during transport, thus minimizing residue on the tube walls.

To further enhance operational efficiency and reduce downtime between product runs, a food-grade wiper disc is positioned on the cable, ensuring the cleanliness of the tubes. Additionally, a continuously operating air knife stationed at the outlet serves to blow air across the discs during their passage, effectively dislodging any residual material and maintaining the system’s optimal functionality.

Streamlined Operations – Centralized Control and Seamless Product Flow

Each processing line’s equipment and tubular drag cable conveyors are connected to the company’s central controller, allowing an operator to operate the entire line from one location. Since the cable conveyors are enclosed systems with no wearing parts, the company has minimized fugitive dust and virtually eliminated spillage and product loss.

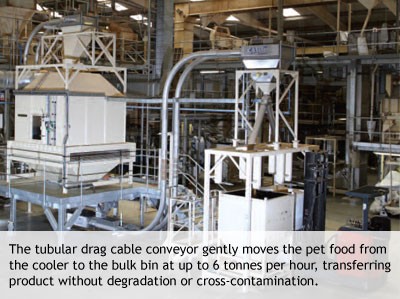

Unlike the traditional conveyor belt system, a tubular drag conveyor gently moves the pet food from the cooler to the bulk bin at up to six tonnes per hour. This allows it to transfer the product without degradation or cross-contamination. In operation, the product is conveyed from an extrusion line to the dryer. The product bottom-discharges from the dryer into the first conveyor and is conveyed to the mixer inlet. After the product bottom discharges from the mixer to the second conveyor, it’s moved to the cooler inlet.

The product then bottom-discharges from the cooler to the third conveyor and is transferred to the packaging station and filled into a bulk bin. The conveyors operate at one fixed speed, and each conveyor first moves the product horizontally a short distance, then vertically to the appropriate height, then horizontally another short distance before discharging.

Improving the Pet Food Production Process With Automated Conveyor Systems

“The cable conveyors have worked well from day one,” says Greenley. “We’ve seen very little product damage because they gently convey it between the equipment. And because they use smaller drives than screw conveyors and bucket elevators do, they produce much less noise and use a lot less power, which helps keep operating costs low.”

Since the cable conveyors are enclosed systems with no wearing parts, the company has minimized fugitive dust and eliminated spillage and product loss, which is common when using a belt conveyor system. “We’ve also eliminated cross-contamination because there are no hang-ups inside the tubes,” says Greenley. “And the conveyors are virtually self-cleaning. Because we run similar products each time and use the wiper disc and air knife, we only have to run them empty for about twenty minutes to clean them between product runs.”

When compared with screw conveyors and bucket elevators, the cable conveyors require very little maintenance. “Maintenance involves periodically checking the discs and cable couplings and inspecting the other components,” says Greenley. “Since each conveyor has a self-tensioning device, we don’t have to make constant cable tension adjustments. And if a disc gets damaged, we can easily replace just that disc without having to replace the whole cable system.”

Cablevey Conveyor Manufacturing Ensures Success

Greenley concludes, “It was a really good installation, and the supplier and their rep have been good partners to work with. And we’re so impressed with the cable conveyors that we’re looking at three more of them for a future project.”

To embark on a similar path of elevated efficiency and reduced operational costs, explore Cablevey’s comprehensive range of conveying solutions today. As one of the industry-leading tubular and belt conveyor manufacturers, Cablevey is committed to delivering innovative and reliable solutions tailored to your needs. Our expertise extends beyond mere product provision – we offer unparalleled conveyor installation supervision to ensure a seamless integration process. Moreover, with a keen focus on sustainability, we excel in cleaning conveyor belts, ensuring not just operational efficiency but also a hygienic and compliant production environment. Revolutionize your production processes with Cablevey Conveyors – where innovation meets excellence. Contact us now to discuss your unique requirements and witness the future of pet food conveying.