Tubular drag systems that operate at slow conveying speeds can assist food processing plants and manufacturers in minimizing product wastage caused by degradation, thus enhancing the overall effectiveness of their processes. So, let us discuss how tubular drag conveying reduces waste and other benefits your manufacturing processes can gain with a Cablevey industrial conveyor belt system.

The Crucial Role of Conveyor Systems in the Manufacturing Industry

While the manufacturing industry highly values speed as a means to increase production, it’s not always the best approach in the context of a belt conveyor system. This particularly holds true for food manufacturers who utilize conveyor systems, often with a conveyor belt for food, to transport specialty items such as roasted nuts, malted barley, breakfast cereals, or fragile cookies and crackers.

As items move along a custom conveyor belt, numerous chances for degradation arise due to the following factors:

- Inadequate inlet design,

- Product shearing,

- Conveyor velocity,

- Temperature fluctuations,

- And separation caused by friction.

Additionally, the bends or turns that materials have to navigate while transitioning to subsequent processes pose further risks. These issues can detrimentally affect the quality of the products and contribute to material loss via breakage and wastage.

What Is a Tubular Drag Conveyor?

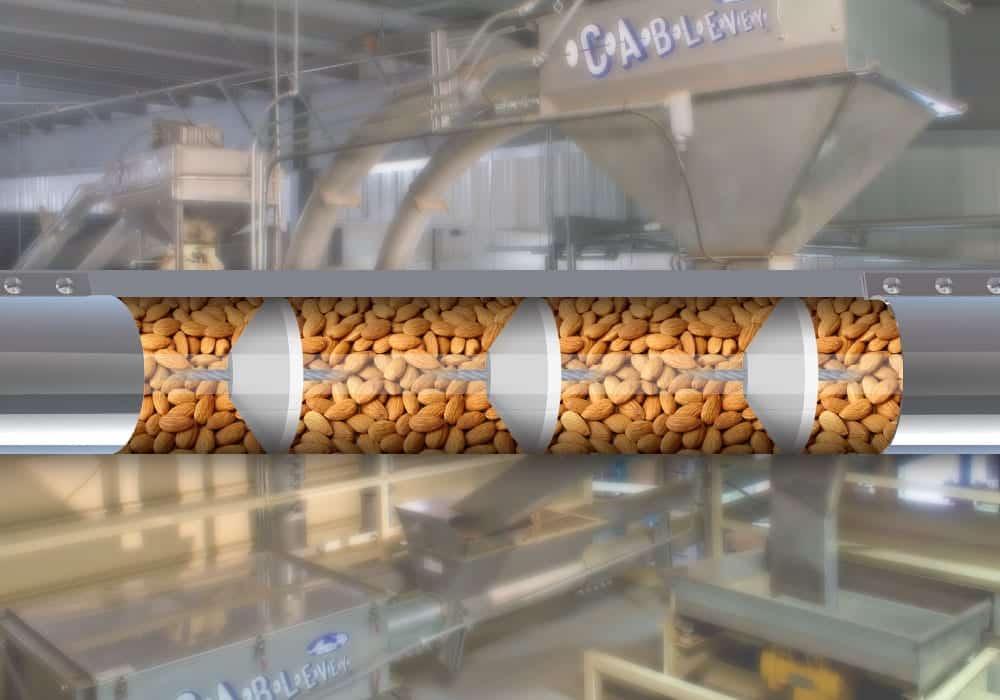

Tubular drag conveying systems are composed of stainless-steel tubes in which nylon or UHMW discs, connected to a stainless-steel cable, are drawn by sprocket drives linked to drive units. The cable often receives a plastic coating for applications involving food-grade standards. The cable-disc mechanism moves through the tube, carrying materials from the loading points to the unloading ports.

This conveyor system, which typically runs at a slow speed of around 100 feet per minute, usually relies on a single electric motor of less than 5HP. This makes it not only highly energy-efficient but also gentle enough to handle a wide range of products. The system’s mild conveying attribute is critical in preventing damage to delicate or specialty materials, which hold higher value when kept whole and undamaged.

How Tubular Drag Conveying Reduces Waste – The Role of Tubular Drag Conveying

Tubular drag conveying systems offer a uniquely gentle, slow-paced means of transporting materials. This care in handling reduces the likelihood of material degradation, a common cause of product waste, thereby extending the useful life of the materials and even the equipment itself.

These systems operate by carefully pulling the material through a tube, avoiding the aggressive agitation or dropping actions found in many conventional conveying methods. This can be particularly advantageous when dealing with fragile materials that can easily break or degrade during transport.

Benefits Over Traditional Conveying Techniques

In comparison to traditional conveying methods such as bucket elevators and augers, tubular drag conveying systems have several advantages. For instance, the enclosed design reduces the risk of contamination from external sources, a feature that is especially important in sectors like the food manufacturing industry where hygiene standards are paramount. Furthermore, the slow pace of these conveyors minimizes product breakage and, subsequently, waste.

Increasing Popularity in Various Industries

Tubular drag conveying systems are gaining increased popularity across various industries. This is especially noticeable in the food manufacturing industry, where the need for maintaining the integrity and quality of the materials often outweighs the need for fast output. However, these systems are also becoming more prevalent in other sectors, including pharmaceuticals, chemical manufacturing, and agriculture. These industries recognize the value of a conveying system that prioritizes the preservation of material quality over the speed of throughput.

The Future of Waste Reduction in Conveying

Looking forward, tubular drag conveying represents a promising approach to waste reduction in various industrial settings. By combining gentle material handling with effective transport, these systems can both improve product quality and reduce operational costs. The result is a more sustainable, efficient, and cost-effective solution for material handling.

Emphasizing Efficiency and Safety of Cablevey Conveyors

Cablevey Conveyors, headquartered in Oskaloosa, Iowa, is a global leader in the manufacture of tubular drag conveyors. Our technology is recognized worldwide, and our dedication to delivering clean, food-safe solutions is second to none. With a strong focus on maintaining the highest hygiene and safety standards, our conveyors are specifically engineered to be food-safe.

This means that they are designed to comply with stringent regulations and standards, minimizing the risk of contamination. Whether you are dealing with delicate foodstuffs or robust raw materials, our systems help ensure that your products are handled with the utmost care.

Improve Efficiency With Our Bulk Material Handling Equipment

In addition, our conveyor systems are incredibly efficient. By using Cablevey Conveyors products, businesses can optimize their production lines, reducing the time and energy required to move materials from one point to another. Our systems are carefully designed to maintain the integrity of your products, which in turn minimizes waste. This makes the entire production process more economical, ultimately leading to reduced operational costs.

Cost Effectiveness of Our Automation Conveyor Systems

Moreover, cost-effectiveness is a core principle in our design philosophy. We believe in providing high-quality, durable conveyor solutions that offer excellent value for money. Our goal is not only to help you improve your processes and reduce waste but also to ensure that the total cost of ownership is as low as possible. The Cablevey Conveyors has a commitment to helping you reduce contamination, minimize waste, and lower costs, contributing to a more successful and sustainable business.

Ensuring Product Quality with the Right Conveyor System

As a key player in your industry, you can’t afford to compromise on quality. Take the first step today towards ensuring optimal product handling. Contact our team to learn more about how our conveyor systems can revolutionize your production process while maintaining the quality and integrity of your products. Get in touch with us today to discover the optimal conveyor system solution for your manufacturing needs.

Reduce contamination. Minimize waste. Lower the costs.

FAQ

What Is a Tubular Drag Conveying System?

A tubular drag conveying system is a slow-paced material handling system where nylon or UHMW discs, connected to a stainless-steel cable, are drawn through stainless-steel tubes to move materials from one point to another. These systems are known for their gentle handling of materials, minimizing degradation and waste.

How Does a Tubular Drag Conveying System Differ From a Traditional Conveyor Belt System?

While both systems transport materials, tubular drag conveying systems do so at a slower pace and are more gentle, reducing degradation and waste. In contrast, traditional conveyor belt systems can often cause more degradation and waste due to inadequate product shearing, inlet design, speed, and temperature fluctuations.

Why Are Tubular Drag Conveying Systems Particularly Beneficial in the Food Industry?

The food industry often deals with fragile and specialty items that can be damaged easily. Tubular drag conveying systems handle these items gently, preserving their integrity and reducing waste.

Are Tubular Drag Conveying Systems Energy Efficient?

Yes, these systems typically operate on a single electric motor of less than 5HP, making them highly energy-efficient compared to many traditional conveying methods.

How Can I Find Out if a Tubular Drag Conveying System Is Right for My Business?

Reach out to our team! We’ll be happy to discuss your specific needs and help determine if a tubular drag conveying system would be a good fit for your operations.