Dried beans are an important staple in many cultures and have been a part of diets for centuries. They continue to be popular in many countries today as they are low in fat but packed with fiber, protein, potassium, iron, and B vitamins. The distribution and processing of dried beans have changed over time, but it remains an important step in their distribution. To preserve the nutritional properties of dried beans, they need to be handled gently and processed the right way before they hit the shelves.

Importance of the Common Dry Bean

The common dry bean is an agricultural legume crop that demonstrates phenotypic and genotypic diversity and global adaptability and has multiple means of preparation and dietary use. The consumption patterns vary significantly among cultures and by geographic region. A broad spectrum of traditions and social interactions discriminate among means of preparation, bean types (size, shape, and color), and end product use.

Dry beans are the second most important legume class globally, right after soybeans, and they are one of the basic foods in Latin America, India, and Africa. In countries where protein-energy malnutrition is prevalent, beans are especially important from a nutritional perspective.

Bean Market in 2023 and Future Trends

Global dry bean consumption indicates a relatively flat trend pattern. From common beans to kidney beans and fava beans, the demand for different bean products is on the rise. In 2018, the global dry bean market topped $30.1 billion. Consumption is forecast to continue to rise over the current decade with a CAGR of 4.3% until 2026. The fact that lentils found in Egyptian tombs still managed to sprout even thousands of years after they’ve been harvested tells us that dry beans are exceptionally shelf-stable foods.

Goya Foods, a large US food company, specializes in producing Latin culinary products (including canned beans). It has seen a dramatic increase in sales of pinto beans, black beans, and other canned products (up to 400%), delivering as many as 24 million cans in just one week. During the COVID-19 pandemic, people turned to cheap and nutritious foods, and when properly stored, dried beans could sit in a pantry for more than a year. Furthermore, food consumption patterns are rapidly changing due to the increasing trend of veganism in the US and Europe (spreading across the world). The number of people who follow an animal-free diet has grown considerably since 2018, and it is one of the industry’s major drivers.

Optimizing Distribution and Processing Techniques for Enhanced Quality

Dry beans are high in protein, fiber, non-digestible starches, and bioactive components. When it comes to distribution, the way beans are handled throughout the food production processing facility can also determine their quality. For example, seed coat damage is cumulative during each stage of physical distribution, and it must be minimized to prevent seed coat splitting. Also, moisture content control is essential for stability in bean storage systems.

A thorough assessment of procedures and strategies used for the distribution and processing of dry beans is necessary for improving the utilization of dried beans. By understanding the food’s chemical and physical components, diversified processing techniques, and inherent constraints that affect the development of innovative and economically-viable products, bean manufacturers will implement required protocols and conveying and processing technology.

Handling and Storage Practices

Dried beans are harvested physiologically mature, and they may be subsequently air-dried to ensure storage stability. To remain stable during storage, beans require a moisture content of less than 18%. Beans with higher moisture content result in fungal spoilage and significant product loss. During dry handling, bean seed coats are subject to physical damage, and careful handling is necessary to avoid excessive seed coat splits and cracks. Dry bean harvesting, storage, bulk material handling equipment, and infrastructure vary significantly from rudimentary processes (in subsistent and rural environments) to sophisticated systems such as an industrial conveyor belt for food (common in urban settings and global markets).

The resulting changes in quality may manifest in color and flavor defects, decreased digestibility, and seed hydration defects. Postharvest quality losses of dried beans increase energy and time requirements for preparation and decrease nutrient bioavailability and palatability. To distribute fragile foods like dried beans, bean manufacturers cannot rely on just any type of belt conveyor system.

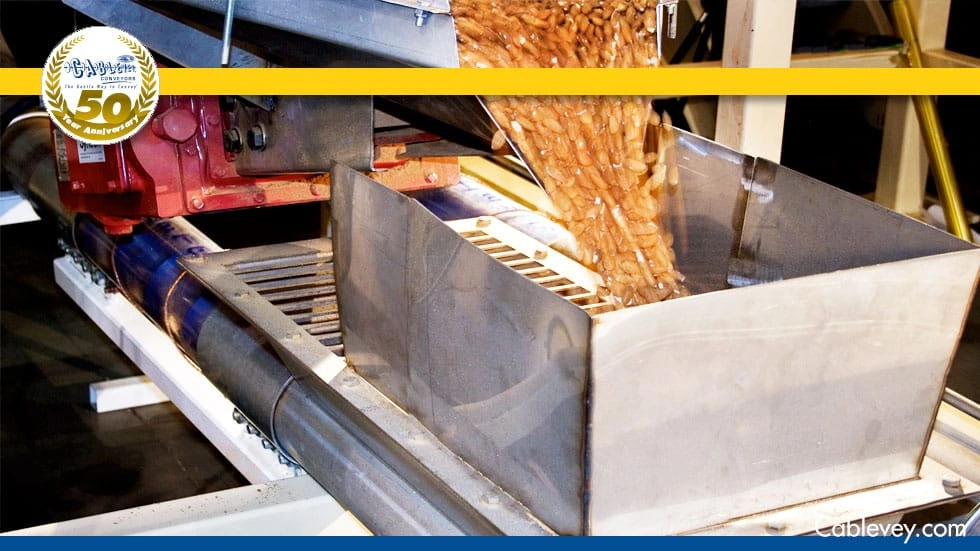

For example, pneumatic conveyor systems, bucket conveyors, or a traditional conveyor belt system won’t minimize bean breakage and keep them contaminant-free as tubular cable and disc conveyors will. Cablevey conveyors are designed to move fragile foods without battering, stress, bumping, or friction (both bean-to-bean and bean-to-conveyor), reducing bean breakage and enhancing cleanliness. They can also be installed in a configuration that fits the processing plant, thus saving space and removing the need for re-engineering processing plants.

Distribution and Processing of Dried Beans

Innovative technology has led to different bean formulations and products, such as frozen, extruded, microwavable, and dehydrated bean products. Cablevey conveying systems can help convey bean products, including packaged dry beans, pre-cooked and more.

Packaged Dry Beans

These are whole, dried beans packaged in retail bags that are suitable for in-home preparation. The pre-soaking and cooking process requires pre-meal planning and cooking time in boiling water, which is why this form of beans is somewhat limited. There is also an increased prevalence of bean medley mixes, which are often used in homemade soups.

Pre-cooked and Dehydrated Bean Powders and Flakes

Cablevey systems can move bean powders and fragile flakes cleanly and safely with virtually no product degradation or separation. Bean crumbles, flours, and flakes are formulated bean mixes, processed and prepared in various food service systems.

Frozen Beans

Fully- or partially-cooked beans marketed as IQF (individually quick frozen) or as a frozen block are great for direct retail distribution or as institutional food ingredients. With the IQF freezing method, beans can be sent into a blast chiller (via tubular drag conveyor) that freezes the item quickly. The conveyor can move the frozen food gently from the chiller right into the packaging area. Beans that have been properly softened and hydrated in low-temperature cooking conditions before being frozen are ready to be used in recipe-based foods.

Quick-Cooking Beans

When it comes to bean utilization, preparation, and cooking, time is a major constraint, which is why many physical and chemical processing methods have been initiated or proposed to address the challenge. Compared to standard processing procedures, the addition of phosphates (salts) to bean soaking or cooking water results in increased hydration yield and a softer bean texture. When this method is used, we get quick-cooking beans with a cooking time of approximately 15 minutes.

Pasta-Type Bean Products

Food manufacturers have attempted to create pasta products from blends of protein concentrates or legume composite flours. Pasta-type products supplemented with about 10% legume flours have been deemed acceptable by taste panels, while pasta products with about 25% legume flours have been reported to have a “beany taste.”

Stages in Dry Bean Processing (Canned Beans)

Typically, beans require gentle handling (to minimize mechanical damage), dry cleaning and sorting, and blanching or soaking before filling and thermal processing. Different bean products have appeared on the market thanks to the rising popularity of convenience foods, such as frozen, extruded, microwavable, and dehydrated bean products. Canned beans continue to be the major processed bean product, and we will describe the stages of the canning process in detail. There are 8 unit operations during bean canning:

- Cleaning or grading,

- Soaking,

- Blanching,

- Pack-style, sauce, or brine,

- Filling and closing,

- Thermal processing,

- Cooling,

- Labeling and casing.

Cleaning and Grading

First, dried beans must go through a clipper cleaner or winnowing mill to remove small pieces of foreign material, dirt, and other extraneous matter. Cleaned beans are then inspected to remove defective and split beans and other extraneous matter (e.g., insects or rocks). It is done either manually or with the use of machine vision systems. If this step is performed before bulk storage, this step may be unnecessary at the canning facility.

Blanching and Soaking

Besides the quality of raw beans, the quality of processed beans is greatly influenced by the methods used in processing. Blanching and soaking procedures are performed to affect the hydration of the bean cotyledon so that the beans can sufficiently soften during cooking. Before they are processed, the initial moisture content of raw beans needs to be between 12% and 16%. There is an initial rapid uptake of water during the soaking stage due to the filling of capillaries on the bean seed coats’ surface. A wax-like, hydrophobic material covers the seed coat to impede water penetration, and as soaking continues, the rate of water uptake decreases because soluble materials get extracted.

What is the goal of soaking and cooking?

To provide beans with a final moisture level of about 53-57%. For soaking, soft water should be used because hard water can result in bean products that will require a longer cooking time. As for blanching, this process aims to provide a uniform product during filling and to evacuate gasses in the beans. Also, it may aid in bean water absorption and provide it with a more desirable texture. After blanching, beans are usually washed in cold water by shaker washers equipped with jets that spray water onto the beans as they rotate in the shakers or reels. During the washing step or through the use of a pneumatic separator, skins and splits can be removed from the blanched beans.

Destoning of Beans

To remove small stones, soaked beans are often run over a water riffle, but some advanced methods combine cleaning, washing, and destoning steps into one operation. Light, floating waste gets removed in the initial floating section, while silt and stones are released in the destoning stage. Ultimately, beans are dewatered, and fine stones are removed. Destoning can be performed after blanching or between the soak tanks and the blancher.

Canned Bean Pack Styles

Beans are canned in various pack styles with different sauce consistency/viscosity and flavor profiles. These include chilled beans, refried beans, baked beans, bean soups, beans with frankfurters or wieners, and beans in sauce or brine. The final characteristics of the product are determined by the ratio of beans to the cover sauce. Brines and sauces also help offer variety and product differentiation, as well as de-commoditized bean products. They often include certain functional salts that aid in preservation. Sauce formulas range from brine-based to tomato-based and can consist of other ingredients, such as starches, flavors, seasoning, beef, and pork.

Filling and Closing

After soaking, blanching, and destoning, the beans are conveyed to the area where soaked and blanched beans are filled into cans (along with brine or sauce). It is an automated process where a specific amount of beans is placed in a can or jar, which is then filled with brine or sauce.

To maintain a high closing temperature, the brine or sauce should be added as close to 100°C (212°F) as possible. Properly filled cans will contain enough sauce to cover the beans after processing and a few weeks of storage. Atmospheric closure occurs when the fill temperature is higher than 60°C, and after closure, cans are passed through a warm-water spray to remove any material adhering to the can.

Thermal Processing

Immediately following can closure, thermal processing is performed for the sterilization of beans in sauce. Beans are low-acid foods and are subject to the FDA’s manufacturing practices regulations for low-acid canned foods. The thermal process required for sterilization is affected by the amount of sugar, starch, and tomato pulp in the sauce formulation and the degree of bean rehydration. In case beans aren’t fully rehydrated before canning, they might absorb the moisture from the sauce or brine, resulting in little or no sauce or brine in the headspace.

Bean Cooling

To prevent thermophilic spoilage, closed cans must be water-cooled immediately after they are processed until the average temperature of the can content reaches about 38°C. Excessive cooling may lead to residual moisture and rusting of can surfaces.

Proper Material Handling

Damage and contamination of dry beans must be reduced to a minimum with proper handling practices and by following established standards for food handling and sanitation. Cablevey provides a tubular drag solution to food manufacturers that need gentle and proper material handling. In most cases, product damage translates into profit loss, making the conveyor system a serious issue that must be addressed immediately.

Cablevey dry bean conveyor systems for processing and production facilities (large to small) are used in dozens of countries worldwide. With over 50 years of experience, we can provide you with a flexible and highly customizable conveying system for your plant configuration and dry beans production needs while ensuring clean and safe environmental conditions, particularly during the cooking and sterilization processes.

Efficient and Safe Dry Bean Transport Solutions with Cablevey Conveyors

Dried beans represent a major food commodity worldwide, and numerous processes are involved in producing this food. Dried beans are processed using different techniques and machinery, such as blanching machines, destoning machines, automatic filling and closing machines, thermal processing equipment (sterilizers), can sealing equipment, and cooling systems, to name a few.

Beans need to be transported quickly and securely during this entire process, with no damage or contamination. Cablevey offers dry bean conveyors that can prevent product damage during the transport processes. Our versatile tubular drag solutions are ideal for food manufacturers interested in reducing material handling costs and ensuring clean products without compromising performance and safety standards. So whether you need a custom conveyor belt for the warehouse or to upgrade your whole system with our solutions, contact us today for more information.