From processing to distribution, ensuring the premium quality of dried beans is no small feat. It’s all about knowing how to maintain quality in dried bean processing and distribution with a strategic approach rooted in best practices and attention to detail. Each step needs rigorous standards and consistent monitoring. This ensures that consumers always receive a top-notch product. Let’s delve into the key practices that uphold this quality throughout the process.

To ensure quality in dried bean processing and distribution, start with fresh, undamaged beans. Clean them thoroughly and dry them to about 10% moisture content for mold prevention. Store in airtight containers in cool, dry places, and routinely inspect for mold or pests. During transport, use protective packaging to avoid contamination. Maintain traceability for accountability, educate distributors on storage and handling, and periodically conduct quality checks. Staying updated with best practices and regulations is crucial for maintaining quality throughout the distribution chain.

Evolution and Importance of Bean Production: From Ancient Roots to Global Nutritional Staple

Due to their exceptional nutritional value, common dried beans are an important food worldwide. The industry has undergone wide production distribution expansions from its origins in South and Central America. In North America, Native Americans grew beans, which the settlers adopted later, and American bean production started to boom by the end of the 19th century.

Beans are popular because they are an exceptional source of vitamins, minerals, proteins, and carbohydrates, but they are inedible in their raw state because they contain various anti-nutritional factors and have a firm texture.

Optimizing Bean Quality: The Role of Commercial Processing and Traditional Cooking Techniques

Commercial processing and traditional cooking methods can greatly reduce or destroy the anti-nutritional factors, softening the beans and turning them into nutritious and safe food. Distribution and processing factors can influence the quality of beans, including cleaning/grading, washing, soaking, blanching, thermal processing, filling and can size, and brine and pack styles.

Dried Beans: Post-Harvesting Handling and Storage

Unless kept cool, harvested green dried beans’ temperature can increase, resulting in spoilage. Postharvest and processing facilities must provide adequate shade and ventilation. They should be stored short-term at around 12% moisture or long-term at around 8-9%. To avoid migration of moisture to the cowpea, stored beans shouldn’t be kept on the bare floor but in steel drums or tins, silos, polythene bags, or rhombus.

Dried beans also need to be conveyed gently, with bulk material handling equipment to keep their integrity, as damaged or broken beans can encourage insect infestation. To starve any insects of oxygen, the storage structures must be airtight and cleaned adequately for storage.

After harvesting, manufacturers need to remove the seeds from the surrounding plant material through a process called threshing. Threshing should be done when the beans are completely dry and when humidity is low. To protect the beans from dirt, damage, and scattering, threshing should be done on a threshing rack.

Drying Threshed Beans Properly to Prevent Molding During Storage

To avoid molding during storage, threshed beans should be dried further on wire mesh trays, plastic sheets, or mats raised on a platform. In dried bean distribution and processing, the dried grains need to be wholesome, clean, well-filled, and uniform in shape, size, and color. They should also be clean from substances that would make them unfit for human consumption or processing.

Dried beans should be clean from discoloration, obnoxious smells, and abnormal flavors, and they should not be musty. Ensure there are no microorganisms or substances that originate from them (for example, fungi or other substances) in amounts that may pose a hazard to human health.

Dried Bean Packaging Must Follow All the Required Regulations

Dried beans should be packed in containers that will safeguard the technological, nutritional, and hygienic qualities of the product. The packages should also be sound, clean, and free from fungal infestation and insects, while the packaging material must be securely closed and sealed and of food-grade quality. Of course, each package needs to contain dried beans of the same type and grade designation.

The recent advancement of pesticide-free hermetic storage for dry commodities is now used in more than 80 countries across the world. It is crucial in semi-tropical and tropical areas due to high temperatures and humidity, while flexible plastic storage structures have been applied to long-term bean storage.

Molds grow exponentially at a humidity level of above 65%, while insects multiply most quickly at high temperatures (30°C and higher). Mold must be prevented from growing because it produces mycotoxins, and lack of moisture and lack of oxygen inhibits its growth.

Canned Beans: Standards of Quality

The US standards for grades of canned beans have been established by the US Department of Agriculture, Agricultural Marketing Service (USDA-AMS). For canned beans packed in sweetened sauce, tomato sauce, or brine, products receiving grade A quality must score at least 90 or higher on a 100-point scale. The absence of defects and character weighed are worth 40 points each, and the color weighed is worth 20 points.

Also, the product must have good character and flavor, be virtually without defects, have a good consistency (if packed in sauce), and have similar varietal characteristics.

Quality Evaluation of Canned Beans

Bean quality can refer to the nutritional, chemical, and physical quality, as well as sensory attributes of the product. Nutritional and chemical measurements performed include oligosaccharides and monosaccharides, resistant and total starch, flavor volatiles, and proximate analysis. As for sensory attributes, they include factors like bean color, size, splits, and degree of packing. Also, it’s important that the processed beans are stored at least two weeks before quality evaluation.

Importance of Cleanliness and Eliminating Breakage in Bean Distribution

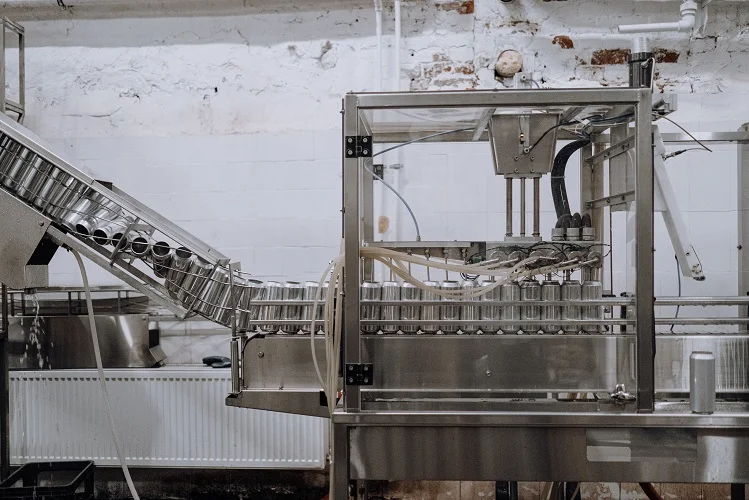

For short-term or long-term storage, dry beans went through a custom conveyor belt to storage silos prior to cleaning. The beans delivered through a tubular cable and disc conveyor system are exposed to minimum risk of breakage and contamination (minimizing the seed coat damage is particularly important when conveying dry beans). Regular checkups during all stages of the physical distribution are essential to minimize seed coat splitting, as the damage is cumulative during each stage.

Dried bean damage is most often associated with dropping and shattering during conveyor transfers. Poorly designed bucket lifts and augers are detrimental and result in damaged seed coats. Tubular drag systems’ features and benefits are superior to other conveyor system designs in which individual beans are dynamic, resulting in bean-to-conveyor and bean-to-bean abrasion.

Minimizing Bean Damage: Best Practices for Safe Dropping and Handling

Bean dropping has the most profound effect on bean damage – dumping into free-standing piles or filling into bins and silos are both situations where seed coat damage may occur. To control seed coat damage, maintaining minimum drop distances and establishing a continuous flow from the truck to the bean pile is recommended, as well as controlling the length of the drop into the bin.

The Significance of Moisture Control in Dried Bean Storage: Impacts and Implications

Moisture content control of dried beans is also crucial for stability in bean storage systems. Adverse distribution and storage conditions could induce bean hydration defects and decrease nutrient bioavailability and seed digestibility, leading to defects known as HTC (hard-to-cook), hard-shell, and bin burn phenomena. Therefore, improved utilization of dried beans can be maximized through a proper understanding of the control and impact of postharvest distribution, storage, and packaging.

Addressing the Challenge of Material Breakage

Many food processing plants rely on conveyor systems to distribute fragile foods within their facilities. In the case of dried beans, seed coat damage leads to waste materials that can affect a plant’s bottom line. Therefore, one of the most critical challenges that need to be addressed is finding a way to distribute dried beans through all the processing stages with a high level of product safety and minimized seed coat damage and breakage.

Include Cablevey Conveyors in Your Production

Cablevey Conveyors has created a one-of-a-kind tubular drag system that uses cables and discs to gently move various materials (for example, delicate, small, and powdered materials). It can move dried beans without stress, friction, battering, or bumping, minimizing bean breakage and seed coat damage. Cablevey’s system enhances cleanliness, offers increased flexibility, and is easy to maintain, which makes it the best solution to meet the requirements of dried bean processing plants.

Dried bean manufacturers can’t rely on buckets, pneumatic conveyor systems, or a typical industrial conveyor belt for food to distribute dried beans throughout their facilities because of their physical properties. Also, keeping them contaminant-free during conveying can also be challenging with these systems. Tubular cable and disc conveyors are enclosed, which prevents foreign particles from getting into the stream.

Explore All the Possibilities With Cablevey

Cablevey’s conveyors can be installed in vertical, horizontal, and curved configurations to remove the need to re-engineer processes and plants. Furthermore, tubular cable and disc conveyors reduce power requirements significantly – a traditional conveyor belt system has maximum motor sizes of up to 50 amps.

In comparison, our largest system uses a maximum motor size of 7.5 horsepower! Our engineering team can design a conveyor suited to move any type of product or ingredient while reducing equipment downtime and maintenance and preserving product integrity.

Dry bean contamination and damage must be minimized through the use of proper handling practices, and the established standards for food handling are important for sanitary control. This can be done through the use of good manufacturing practices, good agricultural practices, and a range of advanced food safety and quality standards, such as SQF, HACCP, and ISO 9000.

How to Maintain Quality in Dried Bean Processing and Distribution – Let Cablevey Be Your Guide

When maintaining quality in dried bean processing and distribution, food processing plants should have a set of policies and principles regarding dry bean handling as well as the right technology to support them. From lima beans and black beans to pinto beans and kidney beans, having a good conveyor belt for a warehouse is essential.Experts at Cablevey Conveyors understand the bean market grade standards, the shelf life of the final product, and that proper and gentle handling means the difference between profit and loss in dry bean production. We know the beans’ life cycle and that they require careful handling, processing, and moving to ensure their integrity. Contact us and check why our tubular drag conveyors are the best choice for your production.