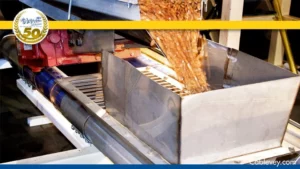

Explore how Nutropica, a leading wild bird seed provider, develops innovative new blends due to Cablevey conveyor selection. The company’s new conveyor solutions enabled the seamless integration of diverse ingredients, ensuring precise and gentle conveying. The flexibility and efficiency of Cablevey’s conveying technologies have revolutionized their production process, fostering creativity in blend formulation while maintaining the highest quality standards in bird seed production.

Nutropica Enhances Their Production Process Thanks to Cablevey’s Outstanding Conveyor Engineering

Nutropica, a renowned name in the bird seed industry, has significantly enhanced its production process by adopting Cablevey Conveyor’s outstanding conveyor engineering. This brilliant move has enabled Nutropica to streamline its operations, improve efficiency, and ensure the highest quality in its bird seed blends.

Cablevey’s industrial conveyor systems are specially designed to handle fragile materials gently, preventing the breakage and loss of seeds and ensuring that every blend retains its nutritional integrity. The customized conveyor solutions provided by Cablevey Conveyors align perfectly with Nutropica’s commitment to excellence, allowing for the seamless integration of various seed types and ingredients without compromising on quality.

Why Is the Choice of Automated Conveyor System Important for Bird Seed Production?

The choice of conveyor engineering is pivotal in bird seed production for several reasons. First, the gentle handling of seeds is crucial for maintaining their quality and nutritional value, which can directly impact the health of the end consumers – the birds.

Cablevey’s tubular cable and disc conveyor systems are engineered to move materials with minimal damage, preserving the integrity of even the most delicate seeds. Additionally, the enclosed design of tubular conveyor systems significantly reduces the risk of contamination and ensures a clean, safe production environment.

This is particularly important in bird seed conveying, where hygiene and purity are paramount. By choosing Cablevey’s advanced conveyor engineering, companies like Nutropica can achieve a balance of efficiency, quality, and safety. This allows them to set new standards in the bird seed industry and ensure the well-being of birds worldwide. Check out the video below to hear one of Nutropica’s owners and his impressions on Cablevey Conveyors’ systems:

Consider Cablevey’s Industrial Conveyor Systems for Your Facilities

When it comes to enhancing operational efficiency and maintaining product integrity within your facilities, Cablevey’s industrial conveyor systems are unmatched. Renowned for our innovative engineering and reliability, Cablevey Conveyors offers a superior solution for handling a wide range of materials, from delicate food products to bulk industrial goods.

Our outstanding systems are designed with precision to ensure gentle handling, minimizing product degradation and loss. The enclosed design safeguards the materials being transported from contamination and contributes to a cleaner, safer work environment. With customizable configurations to fit any facility layout and the capacity to handle diverse material types, Cablevey Conveyors is the ideal choice for businesses looking to upgrade their material handling processes.

Opting for Cablevey’s conveyor solutions means investing in efficiency, safety, and quality, setting your operations up for success in the competitive industrial landscape. If you want to learn more about the efficiency and quality of Cablevey Conveyors, here’s another video where one of Nutropica’s owners discusses their experience of using our systems throughout their production process of developing and delivering a variety of wild bird seed blends.

Contact Cablevey Conveyor and Ensure Gentle Conveying for Your Production Facility

Reach out to Cablevey Conveyors for state-of-the-art conveyor solutions designed to meet the unique needs of your production facility. Our expert team specializes in creating customized conveying systems that promise gentle handling of your materials and products, ensuring their integrity from start to finish.

With a focus on innovation and quality, we tailor each system to minimize product damage and maintain the highest hygiene standards. Whether you’re dealing with bird seeds or any other type of delicate materials, our systems are engineered to enhance your operational workflow. Contact us today to secure a conveying system that aligns perfectly with your production goals and challenges.

FAQ

How Did Cablevey Conveyors Revolutionize Wild Bird Seed Production?

Cablevey Conveyors revolutionized wild bird seed production by providing innovative conveyor solutions that enabled the creation of new blends. Our technology allowed for the precise and gentle integration of diverse ingredients, ensuring high-quality standards and fostering creativity in product development.

What Makes Cablevey’s Conveyor Engineering Stand Out in the Industry?

Cablevey’s engineering stands out due to its focus on the gentle handling of delicate materials, preventing breakage and loss. Our systems are tailored to meet specific production needs, ensuring efficiency and the highest quality in end products, such as bird seed blends.

Why Is Gentle Handling Important in Bird Seed Production?

Gentle handling is crucial in bird seed production to maintain the seeds’ quality and nutritional value, directly impacting the health of birds. Cablevey’s systems minimize damage and preserve the integrity of delicate seeds, ensuring a safe and nutritious product.

How Do Cablevey Conveyors Ensure a Clean Production Environment?

Cablevey Conveyors offers systems that ensure a clean production environment through their enclosed design, significantly reducing the risk of contamination. This is essential for bird seed production, where hygiene and purity are paramount to ensuring the well-being of birds.

What Are the Benefits of Using Cablevey’s Industrial Conveyor Systems?

The benefits of using Cablevey’s industrial conveyor systems include enhanced operational efficiency, product integrity maintenance, and a safer work environment. Our precision-engineered systems are customizable, making them suitable for a wide range of materials and facility layouts.

How Can Businesses Customize Cablevey’s Conveyor Solutions for Their Needs?

Businesses can customize Cablevey’s conveying solutions by working with our expert team to design systems tailored to their specific production requirements. Our company focuses on innovation and quality, optimizing each system for efficiency, safety, and minimal product damage.

What Should Companies Do to Get Started With Cablevey Conveyors?

Companies interested in improving their production process with Cablevey Conveyors should contact our team for a consultation. We specialize in customized automated conveyor systems, offering solutions that ensure gentle product handling and align with production goals and challenges, enhancing operational workflow.