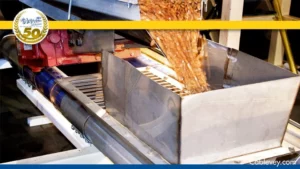

When it comes to the conveying process, is there an innovative solution that offers a dust-free environment and ensures the highest standards in rice handling? Explore how Novarozz, a rice processor, improves sanitary product transport with an enclosed tubular conveyor. The system’s enclosed design not only protects the rice from external contaminants but also preserves its quality throughout the transportation process, marking a significant improvement in the company’s production efficiency and product integrity.

Novarroz is a name that came from being a small water mill by a Portuguese brook over four decades ago. Nowadays, it is one of Europe’s greatest rice manufacturers, both in terms of production size and product quality. Through rigorous quality control measures and a careful eye overseeing each step of the process, Novarroz has managed to make itself synonymous with high-quality produce.

A Company With a Goal – Creating the Best Possible Product

From the discreet brook babbling against the wooden rice mill in the 60s all the way to a modern yield of 15 tonnes per hour, Novarroz has been dedicated to a single objective, and that is generating the best possible product to offer its customers. This path was carved with intelligent and sensible decisions, resulting in a highly optimized, highly-specialized production process.

Dedication to Utilizing Quality Resources and Equipment

When a small company grows to such orders of magnitude, harmonizing tradition and innovation can prove a nuanced and difficult process, as each decision progressively holds more stakes. Novarroz has continuously allocated effort in search of the best resources and equipment, improving their production line and elevating their final product.

For the company, this came to fruition in the form of twelve different product lines, each highly specialized in its own specific uses. From sushi rice to basmati rice, Novarroz has managed to preserve its roots and grow in all directions.

Innovation Is the Key to Novarroz’s Longevity – In Partnership With Cablevey Conveyors

The process of maintaining a unique vision does not consist of leaving innovation by the wayside. By ignoring innovation, many great companies have perished alongside their visions and values. The process consists of making the right decisions and choosing partners carefully. To Novarroz, an essential partnership was created with another company built on its vision – Cablevey Conveyors.

In the difficult and selective process of determining what aspects of innovation are welcome and will synergize with the company’s vision and values, it is a great honor to be an obvious choice among conveyor systems manufacturers. To Cablevey Conveyors, it is a pleasure and a golden opportunity to work with Novarroz in maximizing its product quality to its full potential. Likewise, it’s great to see Novarozz’s production process evolving in service of a product that upholds its values and vision flawlessly.

Cablevey Conveyors Shares Novarroz’s Values and Dedication

Our company has two primary goals: perfecting our conveyor engineering and striving for the best customer service possible, the same two goals we have held for almost 50 years. Cablevey Conveyors is an international company based in Oskaloosa, IA. For almost five decades, we have dedicated ourselves to our tubular drag conveyor systems, crafted as the best possible solution for transporting materials and foodstuffs throughout production plants.

Each system is custom built and the result of carefully carried out customer service. To us, communicating with the customer is a priority of the highest order, alongside perfecting the conveyor solutions our customers need for their production facilities.

What You Should Know About Our Outstanding Industrial Conveyor Systems

With over 30,000 custom-built systems installed worldwide, crafting Cablevey’s technologies to convey over 900 different kinds of products has been a difficult task. It was made possible only through a stern work ethic and the upholding of a vision – offering the best possible product in the smoothest possible way.

The food-grade conveyor system is capable of transporting between 2,12m3 and 56,6m3 of material per hour, reducing breakage to less than 1% with even the most brittle of materials. With attachable cleaning equipment, the system becomes self-cleaning, minimizing downtime and operator effort.

The compact tubular structure of our rice conveyor is a low-noise, low-energy consumption solution for optimizing limited production space. Names such as Unilever, Starbucks, Nestlé, JDE, Cargill, Mondelez, and many others have partnered with Cablevey, and now, so has Novarroz.

If You Want Sanitary Product Transport With an Enclosed Tubular Conveyor, Contact Cablevey Conveyors

Elevate your production efficiency to the levels achieved by Novarroz by partnering with Cablevey Conveyors. Specializing in advanced conveyor solutions, the company offers custom-designed, enclosed tubular conveyor systems that prioritize hygiene, safety, and gentle handling of products. Our innovative conveyor technologies ensure minimal product waste and contamination, perfectly aligning with the needs of industries seeking to enhance operational efficiency and product integrity.

Whether you’re processing rice, grains, or any other bulk materials, Cablevey Conveyors has the expertise and technology to optimize your production process. Contact us today to learn how our conveyor solutions can transform your operations, just as they have for Novarroz.

FAQ

What Makes Cablevey Conveyors Ideal for Rice Processing?

Cablevey Conveyors specializes in enclosed tubular conveyor systems that are perfect for rice processing due to their gentle handling, minimizing breakage and loss. Their dust-free design ensures the highest sanitary standards, preserving the quality and safety of the rice throughout the transportation process.

How Can Cablevey Conveyors Enhance Production Efficiency?

By integrating our industrial conveyor systems into your production line, you can significantly reduce downtime and product waste. Our enclosed systems are designed to handle materials gently, ensuring seamless operations and maintaining product integrity, which in turn boosts overall production efficiency.

Are Cablevey’s Conveyor Systems Suitable for Other Bulk Materials Besides Rice?

Our conveyors are versatile and can efficiently transport a wide range of bulk materials, including grains, nuts, coffee, and more. Our systems are customizable to meet the specific needs of various industries, ensuring optimal handling and preservation of product quality.

What Are the Key Benefits of Using Cablevey’s Enclosed Tubular Conveyor Systems?

Cablevey’s enclosed tubular conveyor systems offer numerous benefits, including enhanced sanitary conditions, protection against contamination, and gentle handling of delicate products. These features contribute to superior product quality, reduced waste, and improved safety and hygiene in the production environment.

How Can I Find Out More About Implementing Cablevey’s Systems in My Facility?

To learn more about how Cablevey Conveyors can transform your production process, you can contact our expert team directly. They will provide detailed information on Cablevey’s conveying systems, conduct a needs assessment of your facility, and offer a customized solution that aligns with your operational goals.