In a strategic move to enhance its operational efficiency, Hilltop Ranch, an almond processor, achieves gentle conveyance with an equipment upgrade from Cablevey Conveyors. This upgrade, focusing on the delicate handling of almonds, ensures the integrity of the nuts throughout the transportation process, minimizing damage and preserving quality, setting a new standard in the industry for product care and efficiency.

How an Almond Processor Achieves Gentle Conveyance With an Equipment Upgrade From Cablevey Conveyors

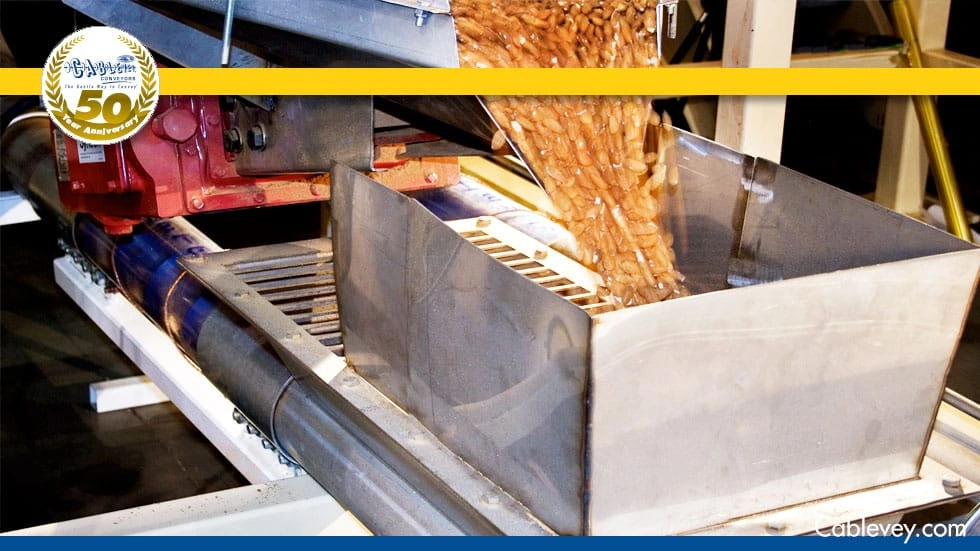

Hilltop Ranch, a leading family-owned almond producer in Ballico, California, significantly improved its almond processing operations by integrating Cablevey’s tubular drag cable conveyor system. Cablevey Conveyors offers systems capable of handling over 50 million pounds of almonds and other nuts yearly. The upgrade was part of an initiative to enhance the efficiency of its processing line while ensuring the almonds remained undamaged throughout their journey within the facility.

Charlie Jahn, the Quality Manager at Hilltop Ranch, highlighted the critical need for conveyor solutions that could transfer almonds delicately across various points of the plant. “One of the challenges we faced when planning the revamped processing line was how to transfer the almonds between various points in the plant while keeping them intact,” Jahn stated.

Hilltop Ranch Found Tubular Conveyor Systems to Be the Best Conveyor Solutions for Almond Processing

Traditional conveyor technologies like high-velocity air power were dismissed due to their potential for causing significant damage to the nuts – a critical concern for high-value products like almonds, where even small percentages in waste can impact profitability drastically. Jahn sought an enclosed tubular conveying system that could accommodate multiple pickups and drop-offs in the plant’s constrained space, especially with the new addition of pasteurization equipment.

After testing pneumatic and aeromechanical conveyors, which proved too harsh on the almonds, Hilltop Ranch opted for Cablevey’s tubular cable conveyor. This system offered a much gentler approach to handling sensitive food products, reducing the risk of product damage and enhancing overall system cleanliness and production efficiency.

Revolutionizing Material Handling With Tubular Drag Cable Conveyors – Not Just for Almonds

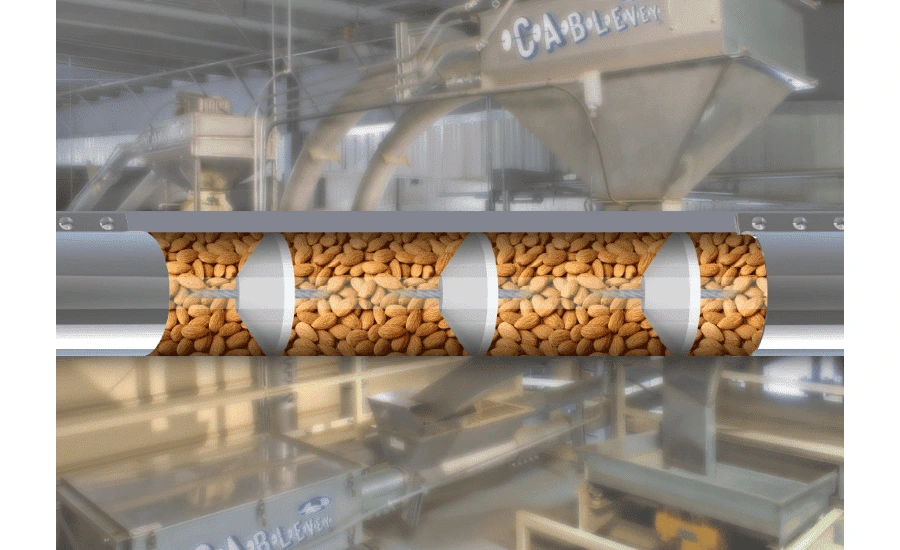

Tubular drag cable conveyor solutions offer a superior method for moving a wide array of products through a sealed tube, utilizing a coated and flexible stainless-steel cable. This system propels the product gently along the tube with solid circular discs attached to the cable, ensuring low-speed transportation without air assistance. This method preserves the integrity of the product while significantly reducing waste, enhancing cleanliness, and boosting production efficiency within a compact system footprint.

Karl Seidel, Cablevey Conveyors’ marketing director, explains that their tubular conveyor systems are perfectly suited for a variety of materials, including coffee, cereal, nuts, snacks, seeds, beans, pet food, and more. Capable of conveying up to 2,000 cubic feet of diverse products per hour – from flakes and pellets to chunks and powders – these systems offer flexible layouts with multiple inlets and outlets for optimal efficiency.

One of the key benefits of these systems is their ability to safely transport easily compacted or sticky materials, which can be a challenge for air-powered systems. Additionally, the enclosed design of tubular drag cable conveyors minimizes the escape of dust and fine granular products, significantly reducing the risk of cross-contamination and the need for excessive cleaning, thus streamlining the production process.

What Were the Benefits Realized After Cablevey’s Conveyor Installation?

The implementation of new conveyor engineering at Hilltop Ranch has brought about substantial improvements to their operations. In the initial three months following the upgrade, the system ran for an impressive 1,400 hours. Reflecting on the performance, Charlie Jahn said, “The conveyors are working out very well. Compared to other systems we tried, they’re more dust-free and easier to clean, and they handle the almonds a lot more gently.”

A key feature of the tubular conveyor is its modular design, which facilitates effortless expansion or reconfiguration to alter its length, path, and the number of inlets and outlets as needed. Karl Seidel points out that making such adjustments is notably more challenging and labor-intensive with pneumatic systems due to their greater number of components and electrical connections.

Contact Cablevey Conveyors – Improve Your Production Facility With Our Stellar Conveyor Technologies

Elevate your production facility to new heights with stellar conveyor technologies from Cablevey Conveyors. Our advanced systems are designed to handle your materials with the utmost care, ensuring efficiency, safety, and cleanliness throughout your production process.

Whether you’re dealing with delicate food items, pharmaceuticals, or any bulk materials, our tubular drag conveyor solutions promise gentle handling, minimal product degradation, and optimal hygiene. With customizable options to fit any operation size and type, we’re committed to enhancing your productivity and product quality. Contact us today and discover how our innovative industrial conveyor systems can transform your production facility.

FAQ

What Makes Cablevey’s Tubular Conveyor Systems Unique for Almond Processing?

Cablevey’s tubular conveyor systems are uniquely designed for gentle handling, ensuring almonds are transported intact. These systems minimize damage and preserve quality, setting a new industry standard for delicate product conveyance.

How Did Hilltop Ranch Benefit From Upgrading to Cablevey Conveyors?

Hilltop Ranch experienced significant operational improvements with Cablevey Conveyors, including a dust-free environment, easier cleaning processes, and gentler handling of almonds, which resulted in higher product integrity and efficiency.

Why Are Traditional Conveyor Technologies Not Suitable for Almond Processing?

Traditional conveyor technologies, such as high-velocity air power, often cause damage to sensitive products like almonds. Cablevey’s enclosed tubular system provides a safer alternative, reducing product damage and waste.

Can Cablevey’s Tubular Conveyor Systems Be Customized for Specific Production Needs?

Cablevey’s tubular conveyor solutions are modular and customizable, allowing for easy expansion or reconfiguration to meet specific production requirements, unlike pneumatic systems that are more complex to adjust.

How Can Cablevey Conveyors Improve Your Production Facility?

Cablevey Conveyors can transform your production facility by providing advanced, gentle handling conveying systems that ensure product integrity, enhance cleanliness, and improve operational efficiency. The company offers solutions tailored to fit any size and type of operation.