Choosing the right conveying system is vital for maintaining the integrity and quality of dry products. To help you make an informed decision, we have crafted a comprehensive conveying systems comparison. By considering the key aspects of each system, you can more easily identify the optimal solution for your specific needs and facility constraints.

Start With Conveying Systems Comparison

There are many types of bulk material handling equipment for you to consider when you need to gently convey dry materials, like breakfast cereal, coffee, snack foods, nuts, powders, grains, pet food, and more. Popular options include cable conveyors, round-link chain conveyors, pneumatic conveyors, bucket elevators, vacuum conveyors, aero-mechanical conveyors, and screw augers.

The Most Important Considerations When Choosing a System

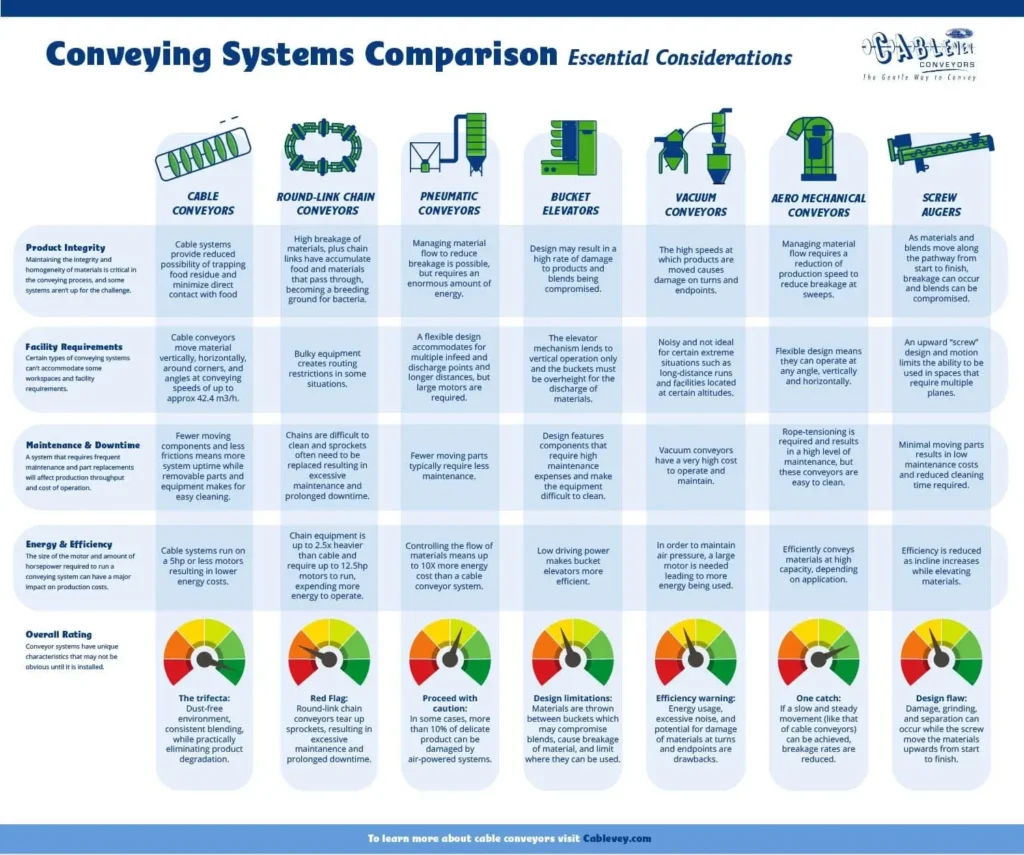

But how do these systems rate head-to-head? What data is available to help you select the best option for your needs? The infographic below provides an easy-to-use comparison chart of conveying options based on four critical considerations:

- Product integrity – Maintaining the integrity and homogeneity of materials is critical in the conveying process, and some systems aren’t up for the challenge.

- Facility requirements – Certain types of conveying systems can’t accommodate some workspaces and facility requirements.

- Maintenance and downtime – A belt conveyor system (or any other type of material handling equipment) that requires frequent maintenance and part replacements will affect production throughput and cost operation.

- Energy and efficiency – The size of the motor and the amount of horsepower required to run a conveying system can have a major impact on production costs.

Understand Each System Before You Decide

Before finalizing your decision on a conveyor belt system, it is crucial to delve deep into the characteristics and functionalities of each option available. These systems play an integral role in determining not only the quality of your products but also the overall efficiency of your operations. That’s why we explore each type of system in detail, evaluating them based on four crucial parameters.

Cable Conveyors

Ideal for gentle handling of delicate products, cable conveyors employ a series of cables to transport materials, minimizing breakage and preserving product integrity. These systems can be customized to navigate around obstacles within a facility, offering a flexible solution for difficult layouts. Despite being energy-efficient, they might require regular maintenance to prevent cable wear and tear, although their downtimes are significantly lower than with other systems.

Round-Link Chain Conveyors

Round-link chain conveyors stand as a robust option, especially suitable for the transportation of heavy or abrasive materials. Built with interconnected round links, these conveyors promise durability and a high degree of reliability, even in rugged environments. However, it’s essential to note that they might require substantial space and could be energy-intensive, affecting the overall production costs.

Pneumatic Conveyors

Pneumatic conveyors use air pressure or vacuum to transport dry materials swiftly through enclosed pipelines. This system excels in maintaining product integrity as it minimizes material contact and contamination risks. Moreover, it can be installed in facilities with spatial constraints, although it might present higher energy consumption compared to other systems.

Bucket Elevators

Offering vertical conveying solutions, bucket elevators are excellent for handling bulk materials like grains and powders. They are equipped with a series of buckets attached to a belt or chain, ensuring minimal material spillage and high-capacity handling. However, they might be limited to vertical or near-vertical transportation and can require significant maintenance to ensure optimum performance.

Vacuum Conveyors

Vacuum conveyors operate by creating a vacuum to transport materials through an enclosed tube. These systems are renowned for their hygiene standards as they limit exposure to external contaminants. Additionally, they can be customized to meet facility requirements, offering a compact and energy-efficient solution. The main disadvantage could be a slight compromise on product integrity, especially for fragile materials.

Aero-Mechanical Conveyors

Aero-mechanical conveyors combine the benefits of pneumatic and mechanical conveying, providing high-speed and gentle material transport. These conveyors are versatile and can be installed in various facility layouts. They are especially good for maintaining product integrity and offer low-maintenance solutions, making them a cost-effective and energy-efficient option but with a slower throughput.

Screw Augers

Aero-mechanical conveyors combine the benefits of pneumatic and mechanical conveying, providing high-speed and gentle material transport. These conveyors are versatile and can be installed in various facility layouts. They are especially good for maintaining product integrity and offer low-maintenance solutions, making them a cost-effective and energy-efficient option but with a slower throughput.

Cable and Disc Tubular Drag Conveyors Are Your Best Bet in Material Handling

Cable and disc tubular drag conveyors emerge as a top choice for several reasons. Firstly, they are renowned for their gentle handling of a wide variety of materials, ensuring product integrity remains uncompromised throughout the conveyance process. Secondly, their enclosed system design significantly reduces the risk of product contamination, maintaining a high standard of hygiene and safety.

Additionally, they demonstrate remarkable versatility, being capable of navigating complex routes, including vertical, horizontal, and three-dimensional pathways with ease. Lastly, they are energy-efficient and require minimal maintenance, offering a cost-effective solution that integrates seamlessly into various production environments.

Why Cablevey Conveyors is Your Go-To Solution

In the realm of material handling and processing, the choice of an appropriate conveying system is essential. As we have seen, each type of conveyor system has its unique attributes, and selecting the right one can greatly influence your operations’ efficiency and the quality of your products. Particularly, cable and disc tubular drag conveyors stand out as a remarkable option, offering a blend of gentleness, versatility, and efficiency, catering to a wide range of material handling needs.

Cablevey Conveyors, with our extensive experience and innovative solutions, is here to guide you in making an informed choice that aligns with your business goals. Don’t compromise on quality and efficiency. Make the smart move today by investing in an industrial conveyor belt for the warehouse or a custom conveyor belt for food for a seamless and fruitful material handling experience. Contact Cablevey Conveyors to explore the best conveyor solutions tailored to your needs.