In an industry where precision is paramount, every craft brewer trusts Cablevey Conveyors for gentle product handling. Our cutting-edge tubular conveying systems are specifically engineered for the delicate transfer of fragile grains, highlighting our commitment to supporting the craft brewing community. Our collaboration with Raccoon River Brewing Company underscores our position as a leader in the sector. We are known for our robust customer service and innovative conveyor solutions that safeguard grain integrity for exceptional brewing quality.

Testimonial for the Great Service From Cablevey Conveyors

David Coy, the lead brewer from Reclaimed Rails Brewing Company, recently praised Cablevey Conveyors for our outstanding customer service. Eighteen years ago, his former business, Raccoon River Brewing Company, bought a Cablevey Conveyor system for their grain elevator.

When Raccoon River closed due to the building being sold, Coy, with a new group of partners, decided to relocate the brewing system. During the installation at the new site, he reached out to Cablevey Conveyors for some spare parts.

To his surprise, Leland Cook, the original salesperson, visited the construction site. Cook offered further assistance by sending Brandee Francisco, an installation expert, who spent a day helping Coy’s team set up the system, offering valuable tips and guidance on aspects they were unfamiliar with.

How Cablevey Stands Out in Customer Support and Partnership

Beyond the innovative conveyor technologies, Cablevey’s commitment to service sets it apart from other conveyor systems manufacturers. The story of Raccoon River Brewing Company illustrates Cablevey’s dedication to its clients.

From the moment of purchase through decades of operation and even during the transition to a new location, Cablevey has been a reliable partner to this company. The exceptional customer service, including personalized visits and conveyor installation supervision, reflects Cablevey’s understanding of this industry’s demands and its commitment to exceeding customer expectations.

A Trusted Partner in Brewing Success

The hands-on support provided by Cablevey, from installation insights to operational tips, demonstrates an unparalleled level of customer care. This commitment ensures that brewers receive a conveyor system that meets their needs. Our clients will also get knowledge and support to optimize their use, maximizing efficiency and product quality.

The Importance of Gentle Grain Handling for Premium Brewing

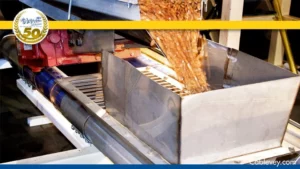

The critical role of gentle handling cannot be overstated in the brewing industry. The quality and consistency of beer rely heavily on the condition of the grains used during brewing. Traditional conveying methods often compromise grain integrity through harsh handling, but Cablevey’s tubular conveyor offers a refined alternative.

By utilizing a gentle conveying process, our systems ensure that grains are not subjected to damaging stresses. Thereby, we preserve their quality and enable brewers to produce beer with superior flavor profiles.

Top-Notch Conveyor Engineering for Protecting Grain Integrity

Cablevey’s conveyors are engineered to transport grains delicately, avoiding the common pitfalls of vibration and shock damage. These are the critical factors needed to maintain the desired brewing quality. Here’s a list of key benefits of Cablevey Conveyors:

- Minimized grain damage – significantly reduces the risk of physical damage to grains during transport, maintaining their integrity for brewing.

- Optimized moisture retention – ensures that the crucial moisture content of grains is preserved, critical for maintaining flavor profiles.

- Reduced waste – by minimizing breakage and damage, less grain is wasted, leading to more efficient use of resources.

- Enhanced flavor profiles – the gentle handling of grains helps preserve their natural flavors, contributing to richer and more distinct brews.

- Improved product consistency – uniform handling leads to a consistent quality of grains, ensuring each batch of brew meets high standards.

- Operational efficiency – streamlines the brewing process by reducing the need for sorting or discarding damaged grains.

- Increased safety – enclosed systems reduce the risk of contamination, promoting a safer brewing environment.

- Cost savings – lower maintenance and operational costs due to fewer breakdowns and disruptions from grain damage.

- Flexibility in handling diverse grains – capable of transporting a wide range of grain types and sizes, offering versatility in brewing options.

- Efficiency in cleaning conveyor belts – our systems are designed for easy cleaning, ensuring conveyor belts remain hygienic and free from contaminants. This is crucial for maintaining the highest standards of grain safety and quality in the brewing process.

- Sustainable operation – by reducing waste and improving efficiency, Cablevey’s systems contribute to more sustainable brewing practices.

Elevate Your Brewing Craft With Cablevey Conveyors

For craft brewers seeking a blend of gentle grain handling and unparalleled customer service, Cablevey Conveyors is the definitive choice. Our tubular conveying system is tailor-made for the brewing industry, ensuring your ingredients are treated with the care they deserve. Elevate your brewing process with our innovative solutions and experience the difference that precision and partnership can bring. Reach out to Cablevey Conveyors today to see how we can help enhance your brewing excellence.