Amid worries about potential infections from dangers like salmonella, listeria, and E. coli, it’s essential to recognize the significance of the right conveyor system can help you avoid food recalls. Those in the food processing industry aim to shield both consumers and their businesses’ financial health from the substantial expenses, image tarnishing, and increased regulatory attention that come with recalls. The ultimate aim is to maintain a hygienic, sterile, and secure workspace.

The Imperative of Preventive Control in Food Production

With a rising tally of outbreaks and recalls linked to post-production food contamination, it’s evident why the preventive controls rule mandates manufacturers to adopt a food safety strategy aimed at thwarting sanitation lapses. This regulation emphasizes cleaning standards for surfaces that come in contact with food, averting both microbial and chemical mix-ups and supervising potential pathogenic elements in crucial machinery like conveyors.

Quality Control and Conveyor System Norms

Consequently, quality control units are heightening their focus on the nature and structure of conveyor systems that align with food safety norms. This entails pinpointing possible collection points for debris and pathogens while also adopting top-tier methods to economize on equipment cleaning, conduct consistent checks, and uphold the surroundings’ conditions.

Expert Insights on Conveyor Designs

“Every day we’re asked for recommendations about types and designs of conveyors,” notes Justin Kerr, the mind behind and the founder of Factor IV Solutions LLC, a consultancy renowned for its food safety expertise across North America. “With conveyors, ideally, there should be minimal harborage points. They should protect products from the environment and be easy to clean.”

Elevating Sanitation Standards

Kerr mentions that Factor IV Solutions guides food processors in formulating Sanitation Standard Operating Procedures (Sanitation SOPs) for conveyors, encompassing routine checks on both food and non-food contact surfaces. Yet, considering contamination hazards, the likelihood of recalls, and the extra expenses tied to consistent cleaning and testing, it’s prudent to opt for a conveyor that reduces numerous potential risks.

Selecting a Conveyor System

In the food processing industry, open bulk material handling equipment, such as bucket elevators or a conveyor belt system, are often more susceptible to being contaminated. In these open setups, products might come into contact with pathogens, contaminants, or ambient moisture. There’s also the risk of products spilling onto the factory floor and entering drains. As a result, those who employ these conveyor types need to enforce rigorous environmental standards, encompassing regular swabbing, evaluations, and quality checks.

Benefits of Closed Conveyor Systems

In contrast, closed conveyor systems effectively insulate products from external elements. However, managing the internal environment remains essential. Among the various kinds of closed systems, tubular drag cable conveyors stand out, especially when transporting delicate, high-value foods. These conveyors transport fragile products through a sealed tube using a coated, bendable stainless-steel drag cable that moves in a continuous loop. Sturdy circular discs, known as “flights,” are connected to this cable, propelling the product along the tube with no need for air. The protective coating on the cable ensures that it remains free from debris, maintaining its complete seal.

Kerr’s Perspective on Enclosed Conveyor Systems

“An enclosed conveyor like the Cablevey provides a controlled environment that reduces the risk of exposure to contaminants and pathogens from outside the system when properly maintained,” notes Justin Kerr. “Because it’s closed, it’s less susceptible to aerosols and overspray from adjacent lines.”

Cablevey Conveyors – Pioneers in the Industry

Based in Oskaloosa, Iowa, Cablevey Conveyors specializes in the design, engineering, and servicing of enclosed cable and disc tube conveyors for half a century. Our products cater to a wide range of materials, from fine powders to whole potatoes. These conveyors are becoming more popular for transporting items like pet food, coffee, cereals, nuts, produce, and other specialty foods.

Consistent Cleanliness in Tubular Cable Conveyors

“When we conducted trials and verification testing, we found that tubular cable conveyors maintain greater repeatability cleanliness over a longer period of time than open systems due to the controlled environment within the enclosure,” says Kerr. Furthermore, Kerr highlights that closed conveyors greatly minimize the chances of contamination by reducing potential harborage areas. “Tubular drag cable conveyors are very simple in construction, without standard joints, threaded bolts, and plastic-to-metal connections,” says Kerr.

Superior Cleaning

Kerr highlights another benefit – these enclosed conveyors enable the wet cleaning method that quickly and effectively floods the systems using water and sanitizes without disassembly or wetting the surrounding areas.

An Overview of the Wet Cleaning Procedure

While not every food processing material is compatible with wet cleaning, this method reduces the risk of contamination for various other food types. The wet cleaning method starts with a water rinse, then introduces a foaming solution, followed by a sanitizing rinse, and concludes with another water rinse. After ensuring the system is completely cleansed, drying is facilitated using urethane wipers attached to the discs of the tubular conveyor, functioning similarly to a squeegee, clearing any leftover water.

Ensuring Equal Cleaning Across Surfaces

“Within the tubular system, all wash factors can be repeatably controlled – water chemistry, temperature, physical action, and time – so every surface is equally cleaned,” says Kerr. Additionally, transparent tubes can be used, providing the added advantage of allowing visual checks or confirmations. Since the system doesn’t require disassembly for comprehensive cleaning, the entire procedure can be completed in a span of 20 to 90 minutes, based on the system’s design, the type of product, and the required cleanliness level. This approach notably decreases interruptions and halts during shifts in production and removes the necessity for extra specialized conveyor routes. Routine cleaning processes can be managed automatically via the facility’s distributed control system.

Benefits of Cablevey Conveyors in Cleaning

“A benefit of Cablevey is the repeatability and verification of surfaces cleaned and the ease of maintaining them,” says Kerr. “You can do verifications against cleanliness and hold [the cleanliness] over a greater period of time.” When a food processing company needs to verify if a conveyor aligns with its hygiene standards, manufacturers such as Cablevey typically permit their quality assurance squads to conduct pre-purchase evaluations. “Sometimes customers come to our test lab so they can run product and conduct swab tests before and after wet cleaning, and review the results for themselves,” says Morgan Bailey, communication specialist at Cablevey Conveyors.

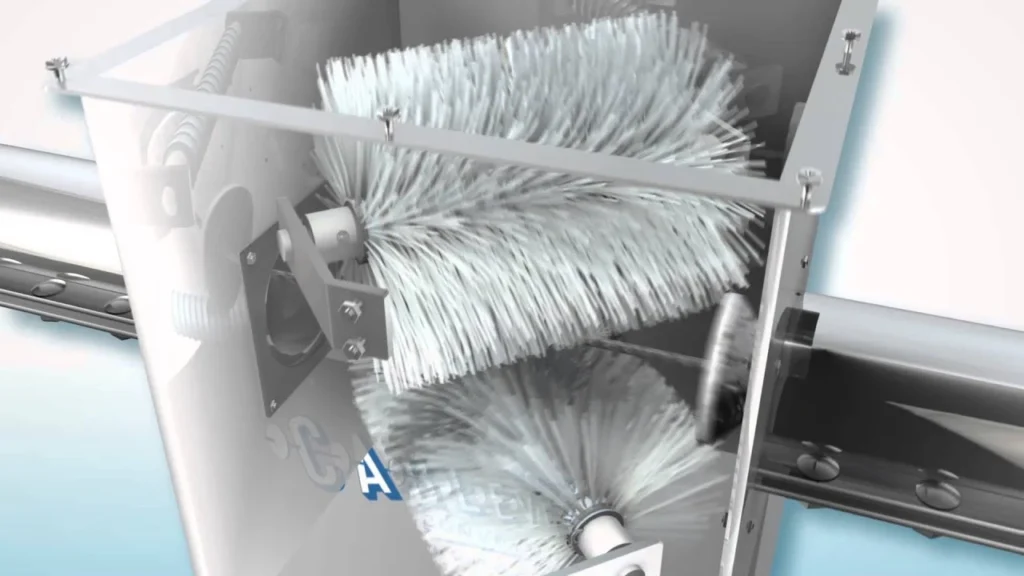

The following video explains how our Clean-In-Place system works.

Industry Stakes and Contamination Concerns

In the food processing industry, when it comes to ensuring safety, there’s a lot on the line. Given the ever-present risk of contamination by dangerous pathogens, food processors aim to safeguard both public health and their company’s financial health from the hefty expenses related to product recalls. Consequently, quality assurance teams consistently and meticulously assess the design and type of conveyor systems used.

The Rising Popularity of Enclosed Conveyors

Enclosed conveyors that are capable of automated wet cleaning can help mitigate risk and prevent many safety issues. These conveyors provide an extra level of protection by keeping debris and pathogens from collecting. They also save on costs by eliminating the need for manual cleaning. As processors continue to seek ways to improve safety, enclosed conveyors will become an increasingly popular choice.

The Critical Role of Closed Conveyor Systems in Food Safety

The danger of contamination from harmful pathogens such as salmonella, listeria, and E. coli is perpetual, leading food processors to protect the public and their companies’ bottom lines by keeping working environments safe, clean, and sanitized. That’s why you should use closed conveyor systems to mitigate risk and prevent safety issues related to sanitation.

Regulatory Emphasis on Sanitation and Equipment Monitoring

It is no surprise that the preventive controls regulation requires manufacturers to create a food safety strategy to prevent sanitation deficiencies, given the rising number of outbreaks and recalls linked to post-processing food contamination. The regulation covers sanitation procedures for food-contact surfaces, prevents microbial and chemical cross-contamination, and monitors environmental pathogens in crucial equipment such as conveyors.

A Deeper Dive into Conveyor Safety Standards

Quality assurance teams are paying more attention to the type and design of conveyance systems used to help meet food safety standards. This includes identifying potential harborage points where debris and pathogens can collect and implementing best practices to save on equipment cleaning costs, perform regular testing, and maintain the environment.

Justin Kerr on Conveyor Design

According to Justin Kerr, founder of Factor IV Solutions LLC, a food-safety consulting firm that has assisted hundreds of food manufacturers and harvesting businesses across North America, we are constantly asked for advice on conveyor types and designs. For conveyors to work properly, there should be as few harbourage points as possible. Product protection from the environment and ease of cleaning should both be guaranteed.

Formulating SOPs with Factor IV Solutions

Factor IV Solutions helps food processors to create sanitation Standard Operating Procedures (SOPs) for conveyors that test food and nonfood surfaces for sanitation. However, regularly verifying and testing food and nonfood surfaces may increase the risk of contamination, consequent recalls, and additional cleaning and testing costs, so it is best to select a conveyor that eliminates as many risk factors as possible.

The Right Conveyor System Can Help You Avoid Food Recalls

Open conveyor systems, such as bucket elevators and belt conveyors used in food processing, are more susceptible to contamination. Products using open conveyors can become contaminated with pathogens, contaminants, or moisture from the surrounding environment. It’s also possible for spills to occur on the plant floor or for material to end up in the drains. Because of this, processors that utilize such conveyors must have stringent environmental controls, including continuous swabbing, testing, and quality assurance. To determine which conveyor system is best suited to meet your needs, check out our conveying system comparison chart.

An Introduction to Closed Conveyor Systems

Another advantage of closed conveyor systems is that they effectively seal off products from the outside environment. Even then, it is necessary to control the environment. The closed systems vary in design, one popular example being tubular drag cable conveyors when conveying high-value foods. A coated, flexible, stainless-steel drag cable gently moves products through a sealed tube. Solid circular discs (called “flights”) are attached to the cable, which pushes the product through the tube without using air. Because the cable is sealed, no debris accumulates within its strands.

According to Kerr, an enclosed conveyor like the Cablevey provides a controlled environment that minimizes the danger of contaminants and pathogens from outside the system. It is less likely to be contaminated by aerosols and overspray from adjacent lines because it is enclosed.

Cablevey Conveyors – Half a Century of Excellence

Cablevey Conveyors has been designing, developing, and servicing enclosed cable and disc tube conveyors for over 50 years, with installations in over 65 countries. In addition to conveying fine powders and bulky whole potatoes, products are increasingly used to move coffee, breakfast cereals, nuts, produce, pet food, and specialty items.

According to Kerr, the controlled environment inside tubular cable conveyor enclosures results in higher repeatability and cleanliness over more extended periods than open systems. He adds that closed conveyors significantly reduce potential harborage points for contamination. Also, he mentions that tubular drag cable conveyors are extremely easy to construct since they lack standard joints, threaded bolts, and plastic-to-metal connections.

The Efficiency of Wet Cleaning in Enclosed Conveyors

Wet cleaning uses enclosed conveyors to clean and sanitize material handling systems without wetting the surrounding areas. This ensures fast and effective cleaning and sanitizing without disassembling the systems. Not all food processing materials are suitable for wet cleaning, but wet cleaning minimizes potential contamination for other types of food. The procedure begins with a water rinse, after which come a foaming agent, a sanitizing rinse, and at the end a final water rinse. After the system is flushed out thoroughly, drying is accomplished by attaching wipers made of urethane to the tubular conveyor’s discs, which function as a squeegee, removing any residual water.

Ensuring Uniform Cleaning with Tubular Systems

According to Kerr, every surface can be equally cleaned within the tubular system, thanks to water chemistry, temperature, physical action, and time. Clear tubes can be used for visual inspection or verification as an added benefit. The system can be cleaned thoroughly and efficiently without taking it apart, saving time ranging from 20 to 90 minutes depending on the system layout, product, and required cleanliness level. This method can significantly decrease downtime and disruptions during production changeovers and eliminate the need for extra dedicated conveyor lines. Cleaning can be automated through the plant’s distributed control system. Kerr also mentioned that Cablevey’s advantages include the verifiability of cleaned surfaces and their ease of maintenance. Verifications against cleanliness can be maintained over a more extended period.

The Importance of Pre-Purchase Testing

Before purchasing a custom conveyor belt for food, equipment suppliers such as Cablevey allow quality assurance teams to perform sanitation tests to ensure that the conveyor meets the company’s criteria. “Customers can come to our test lab to conduct product and swab tests before and after wet cleaning and review the results for themselves,” says Morgan Bailey, communication specialist at Cablevey Conveyors.

Staying Ahead of Safety Concerns in the Food Processing Industry

There is a great deal at stake for food processors when it comes to avoiding safety issues. Safety issues are always a concern, particularly when it comes to harmful pathogens, as the public and companies’ bottom lines are protected from massive costs that result from recalls. Quality assurance teams, therefore, examine the type and design of conveyance systems continuously and closely, whether it’s an industrial conveyor belt for a warehouse or some other enclosed belt conveyor system.

The Future of Conveyance Systems – A Shift to Enclosed Solutions

Wet cleaning can be automated to help mitigate risk and avoid a variety of safety hazards. These enclosed conveyors keep debris and pathogens from accumulating, saving money by eliminating the need for manual cleaning. Enclosed conveyors will become increasingly popular choices as processors continue to seek ways to enhance safety. Don’t miss out on this game-changing innovation – connect with Cablevey Conveyors today and discover how our solutions can elevate your production process. Prioritize safety, efficiency, and cost-effectiveness with Cablevey Conveyors.