In the competitive world of food processing, learning how a tubular conveyor protects delicate products is a must. After all, all reliable conveyor manufacturers want to offer conveyor engineering solutions that promise the integrity of high-value products like coffee, snacks, nuts, cereals, and pet food. With insights from industry experts and a deep dive into the benefits of gentle handling, we present Cablevey Conveyors as the superior solution for preserving the quality of your precious food products.

The Critical Need for Gentle Handling in Food Processing

In the food processing industry, where the transportation of delicate, high-value products like snacks, cereal, nuts, coffee, and dry pet food is a daily operation, minimizing material breakage and loss is crucial. Traditional methods of transportation often fall short, subjecting delicate items to unnecessary stress and damage, thus affecting profitability and brand reputation.

A slight variance in product waste, from 1 percent to 5 percent, can significantly impact a company’s bottom line, making the choice of bulk material handling equipment essential. Traditional conveyor belt systems often fail to provide the necessary care, leading to product degradation during transport. That’s when you should be introduced to a game-changing alternative – a tubular conveying system.

The Impact of Handling on High-Value Food Products – A Case Study on Macadamia Nuts

When a macadamia nut is cracked, its market value can plummet by half. Instead of commanding a premium price, these damaged nuts are usually sold at a steep discount and are often ground up for use in cooking or further processing along the food production line.

“Delicate, high-worth food items require careful handling to avoid breaking them into smaller pieces or reducing them to dust. Such damage drastically reduces the item’s value, necessitating the removal or disposal of the affected portions to avert potential quality concerns that might lead consumers to seek alternatives,” Gary Schliebs, a seasoned advisor on the design of food processing equipment, plant configurations, and workflow management, explains.

He further notes, “Occasionally, over 10 percent of a sensitive product can be ruined by systems using high-speed air for transportation. This is particularly detrimental as it tends to occur after the product has undergone value-adding processes, only to be diminished by an ill-suited choice of conveyance equipment.” Schliebs emphasizes this point.

The Limitations of Traditional Conveyor and Pneumatic Systems

For the transportation of delicate food products, it’s advisable for processors to steer clear of industrial conveyor systems that subject these sensitive items to harsh conditions during transit, potentially compromising their quality yet ensuring the process remains highly efficient. Recognizing this requirement, numerous food processors are re-evaluating the use of systems that propel fragile, high-value goods at great speeds through tubes and around bends, leading to their abrupt release into bins or containers.

Pneumatic and Belt Conveyor Systems in Food Processing – Efficiency vs. Product Integrity

Pneumatic conveyor systems operate by generating air pressure that is either higher or lower than the surrounding atmosphere. These systems are categorized into two primary types: dilute phase and dense phase, which vary in their operating speeds and pressures. Additionally, both types can be set up to function either by creating positive pressure or by forming a vacuum.

Within the dilute phase method, food items are carried aloft by air as they move at speeds ranging typically from 3,400 to 5,000 feet per minute through the conveyor tube. Although these products generally remain intact on straight segments of the path, the systems’ bends and curves can force them into tight spaces, causing rapid directional changes and potential damage. This scenario is particularly problematic for high-value food products, which may be too delicate to withstand such treatment.

Both of these systems are common in the food processing sector. However, they can compromise the integrity of fragile food items. For instance, in the coffee industry, the high-velocity air conveyance can damage the beans, diminishing their flavor and aroma – a point stressed by Gary Schliebs, a renowned process engineer.

The Downside of Aeromechanical and Dense Phase Systems

In dense-phase pneumatic conveyor systems, the product, being either too heavy or abrasive, does not float in the air but moves at a slower pace compared to dilute-phase systems. Despite operating at reduced air speeds, approximately 700-1,500 feet per minute, these systems can still pose a risk of damage to delicate food products, especially at turns and curves.

Aero mechanical conveyors, on the other hand, utilize a distinct transport mechanism. These systems are enclosed and boast high-capacity mechanical conveyance, where a cable fitted with discs at regular intervals speeds through a tube, driven by sprockets at both ends. This setup creates a swift-moving air flow that matches the speed of the discs, propelling the product through the tube. Yet, such systems can subject sensitive items to rigorous conditions during transit, potentially compromising their quality.

Schliebs points out, “Delicate or easily crumbled food items transported at high speeds are at risk of getting damaged, especially when the conveyance involves sudden directional changes or forceful exits. This vulnerability is common to both pneumatic and aero mechanical conveyor systems.”

Alt-Text: Cablevey Conveyors testing facility

Introducing Tubular Cable Conveyors – A Superior Alternative

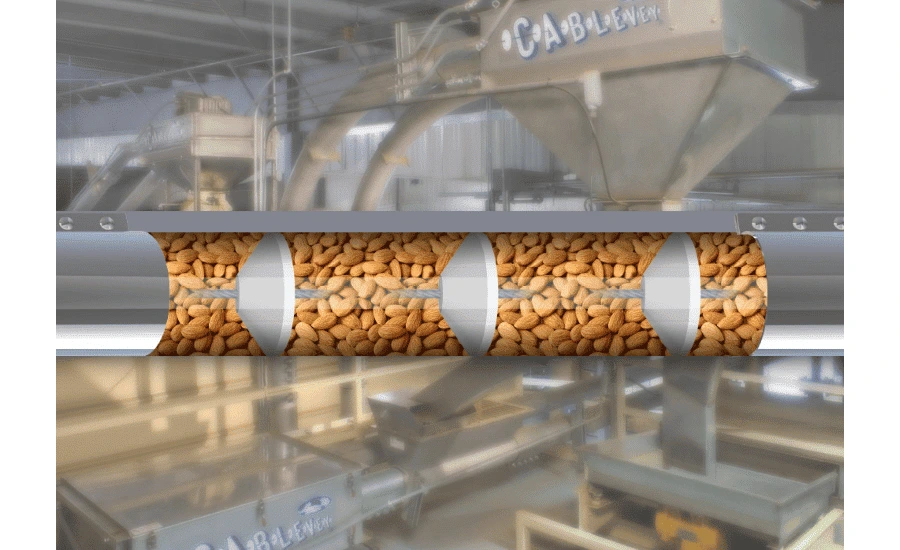

In the quest for more efficient and gentle handling of delicate, high-value food products, tubular cable conveyors emerge as a superior alternative to traditional conveying methods. Designed to address the critical challenges faced by food processors, these innovative conveyor solutions minimize damage and preserve the quality and integrity of products during transport.

With their unique method of moving items through a sealed tube using a cable and disc assembly, tubular cable conveyors provide a seamless, low-velocity conveyance option. This type of conveyance stands out for its ability to handle fragile items with the utmost care.

The Unique Benefits of Tubular Cable Systems

Tubular cable conveyors, such as those offered by Cablevey Conveyors, present an innovative solution for transporting sensitive food products. Utilizing a flexible, coated stainless-steel cable, these systems move products through a sealed tube gently, effectively reducing the risk of damage. This custom conveyor belt technology is particularly advantageous for handling a variety of food products, including those prone to sticking or compacting.

- Maximizing Product Integrity and Value With Cablevey Conveyors

The Cablevey Conveyors tubular cable system represents a significant advancement in automated conveyor systems designed to minimize product damage and waste. With the ability to gently transfer products at low speeds, it ensures that high-value food items maintain their quality and market value.

- Design and Efficiency for Modern Food Processing

The modular construction of Cablevey’s conveyor belt system allows for easy adaptation to various food processing needs. Furthermore, the system’s efficiency in handling sticky or easily compacted materials sets it apart from traditional pneumatic conveyor systems.

- Environmental and Operational Advantages

One of the standout features of Cablevey’s solutions compared to other conveyor systems manufacturers is its energy efficiency. Unlike traditional pneumatic conveyors that require significant power, these systems operate quietly and consume less energy. This not only contributes to a more sustainable operation but also enhances the work environment, allowing for normal conversation levels during operation.

Tubular Conveyor Protects Delicate Products With Advanced Conveyor Systems Manufacturers

The transportation of delicate, high-value food products demands a conveying solution that combines efficiency with gentle handling to minimize damage and preserve product quality. Tubular cable conveyors, with their innovative design and low-velocity operation, offer an optimal solution that addresses these needs effectively.

By choosing Cablevey Conveyors, food processors can benefit from a state-of-the-art automatic conveyor system tailored to protect their valuable products throughout the transportation process. Don’t let traditional conveying methods compromise your product quality and bottom line. Contact us today to discover how our tubular cable conveyor technologies can transform your material handling operations and safeguard the integrity of your high-value food products.