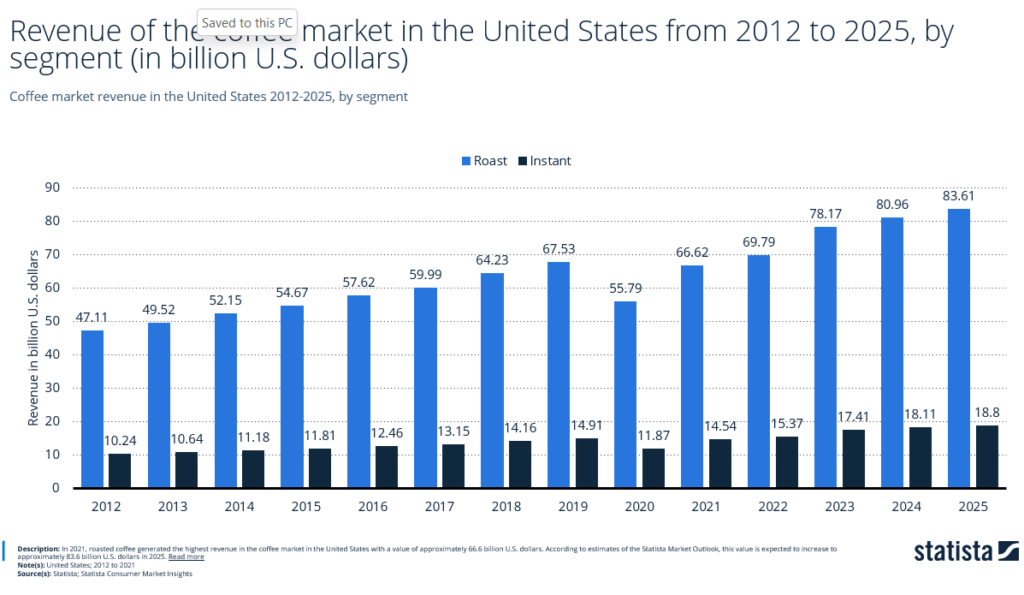

Do you want to know more about coffee industry trends for 2023? Coffee is a staple in our society, and the coffee industry continues to grow, with US sales in 2022 at $69 billion in roast and $15 billion in instant. By 2025, those numbers are projected to grow to $83 billion in roast and $19 billion in instant coffee sales in the US. Gather a better understanding of the forecasts for 2023 so that you can make a clear business plan and a decision on how to improve your production.

Growth presents a valuable opportunity, yet it demands strategic thinking, especially concerning the conveyance of pet foods within an establishment. How are businesses gearing up to manage such expansion within their processing centers?

How Was Research Conducted and Findings Reached?

In October 2022, Cablevey Conveyors collaborated with the independent analyst group Ascend2 to execute a study called Assessing and Introducing New Conveyor Systems. This comprehensive 16-page report (available for download here) gathers insights from 290 experts in the food processing sector across the US and UK regarding pivotal aspects of assessing conveyor technologies.

We’ll now delve into the responses of 106 specialists involved in coffee processing. How are they gearing up for expansion? Leverage these insights and access the full report to equip yourself with knowledge about upcoming trends in the coffee realm.

Before we start, check the recorded growth of the coffee market so you can realize how the trajectory will continue to expand.

The First Finding – Prepare Funds for Growth

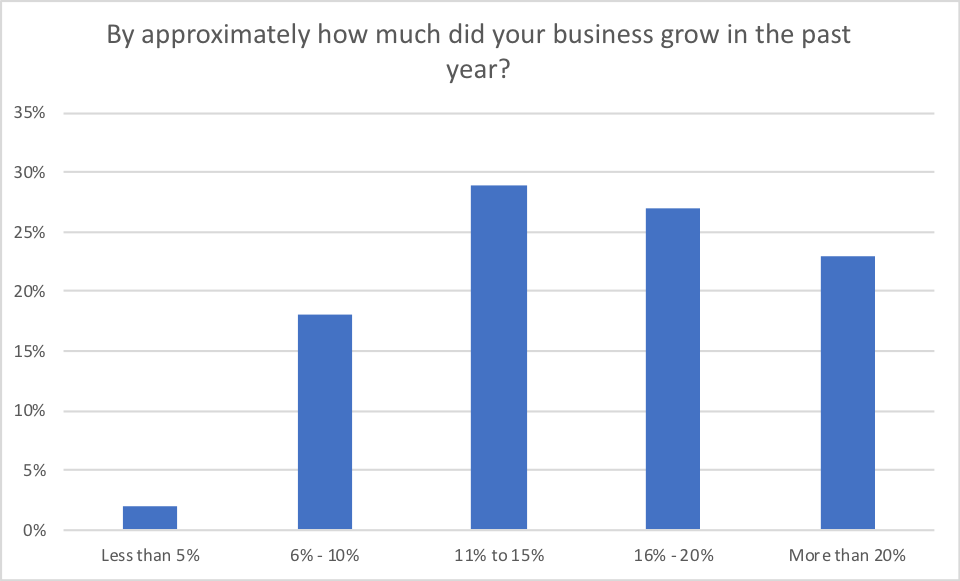

A notable 86% of establishments involved in coffee processing plan to augment their expenditure on conveying machinery and upkeep in the upcoming year. Additionally, 35% indicate a substantial rise in their allocated funds to capitalize on growth prospects. What’s prompting this surge in spending?

The rise in budget stems from the significant expansion these companies witnessed over the last year. Impressively, 79% of establishments saw a growth of 11% or higher. Given such a surge, it’s imperative for these facilities to strategize and enhance their coffee conveying potential to cater to the growing demand.

Second Finding – Automatic Conveyor System That Best Optimizes Facility’s Workspace

A crucial aspect of expansion is assessing your workspace and facility needs. Which conveyor systems align best with the space at your disposal? Are you making the most of the available area?

A whopping 98% of those in the coffee sector indicated they are enhancing their work areas and infrastructure needs. What’s their approach? Based on feedback from coffee processing experts, a tubular conveyor with a cable and disc tops the list, with 54% recognizing them as the prime solution for space optimization.

How to Determine What Automated Conveyor System Is Appropriate for Your Facility?

Here are some inquiries to consider when determining the best conveyor systems to make the most of the space in your establishment:

- Do you possess the required floor area or overhead clearance for specific conveyor models?

- Is the conveyor system’s design structured to ensure convenient cleaning and upkeep, safeguard employee well-being, and maintain efficient operations?

Here is one of Cablevey’s short videos that illustrates a coffee plant’s conveyor blueprint and methods to maximize space, uphold the integrity of the coffee beans, and ensure quality retention.

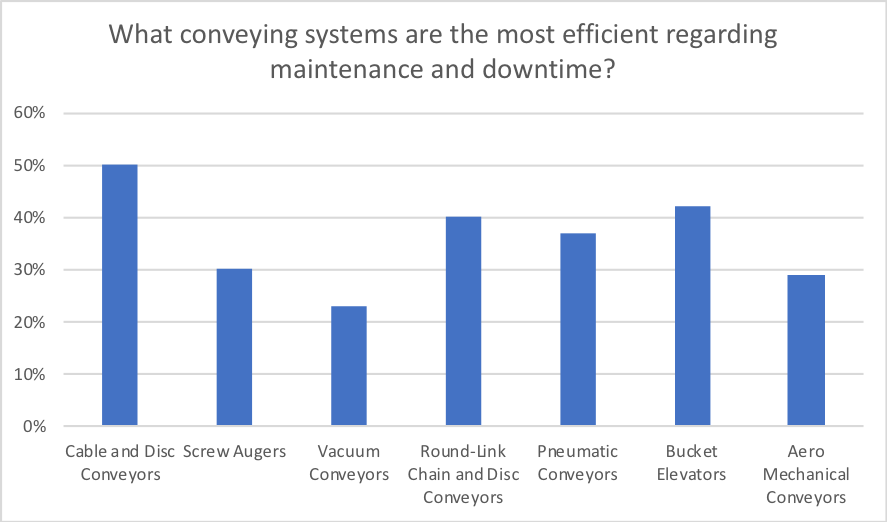

Third Finding – Considering Downtime and Maintenance When Planning Factory Operations

When it comes to conveying coffee, efficiency in maintenance and minimal downtime are paramount. Cable and disc conveyors stand out, with 50% of users preferring them by a significant difference. Following behind tubular conveyors with a cable, bucket elevators, and round-link chain conveyors also rank high on the list of favorites among industry professionals. These systems have proven their worth in both reliability and performance.

Bonus Info – Why Are Tubular Conveyors So Popular?

Tubular conveyors are gaining widespread popularity due to their enclosed design, which ensures the protection of materials from contaminants and the environment. Additionally, their conveyor technologies for efficient and gentle handling of products minimize damage and product loss. Their versatility allows for conveying a variety of materials, making them a favorite choice across multiple industries.

Cablevey’s tubular drag conveyors are engineered with straightforward pneumatic tensioning for the cables, ensuring minimal upkeep. Additionally, the design facilitates effortless cleaning, offering clean-in-place techniques that enhance operational efficiency and curtail downtime.

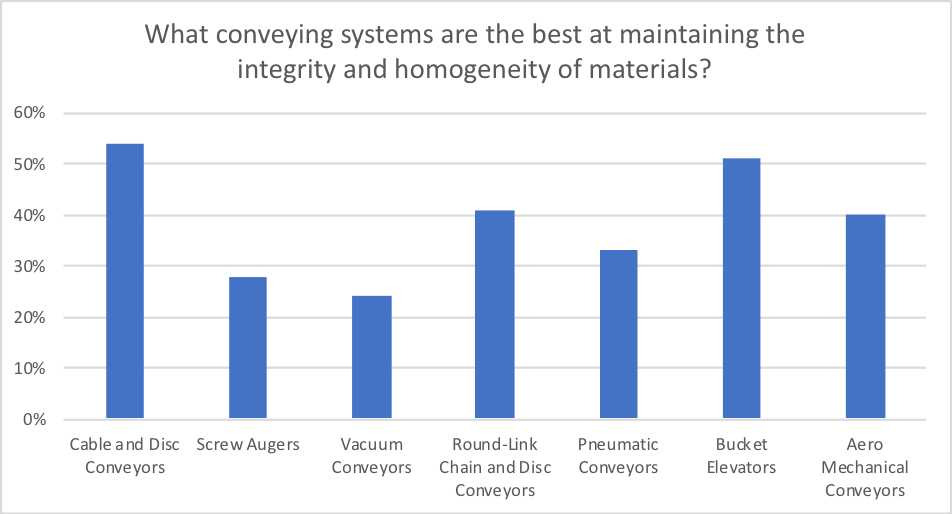

Fourth Finding – The Ideal Approach to Preserving the Quality of Conveyed Coffee

The moisture level of a processed coffee bean typically sits between 10-12%. Due to this, beans become fragile and susceptible to vibration, shocks, and shifts in humidity. Additionally, the fine consistency of ground coffee means it demands gentle handling.

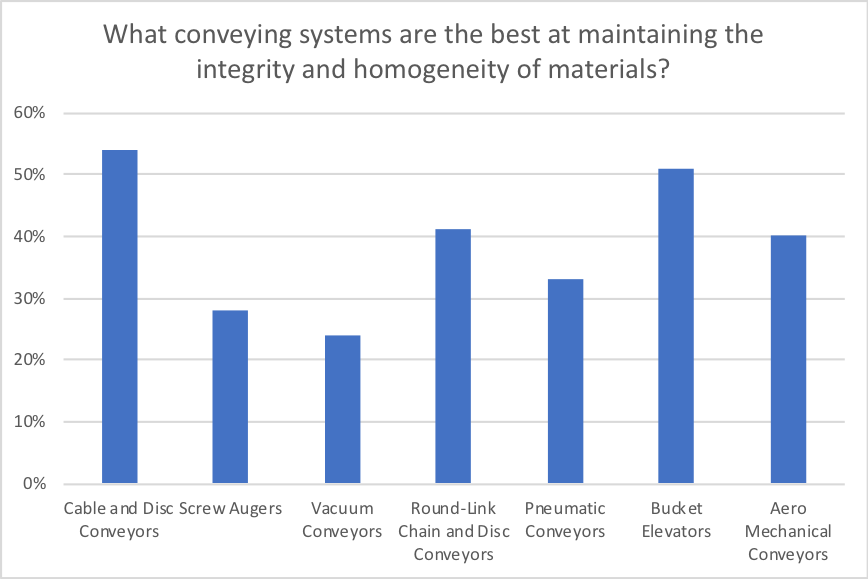

Your chosen conveying system should prioritize preserving the quality and consistency of your coffee beans. So, which system do coffee industry experts rate highest for preserving coffee bean integrity? Again, cable and disc conveyors top the list, with 54% preference.

Questions to Ask Yourself When Selecting a System

When choosing a conveyor system, it’s crucial to consider the specific needs of your product and facility. Ask yourself about the system’s efficiency, ease of maintenance, adaptability to your workspace, and ability to preserve the quality of the materials being conveyed.

When assessing a conveyor system with product quality in mind, consider these two questions:

- Can the system ensure optimal cleanliness without extensive downtime?

- Does the system transport your items gently to prevent damage and reduce wastage?

Fifth Finding – Remember Energy Efficiency

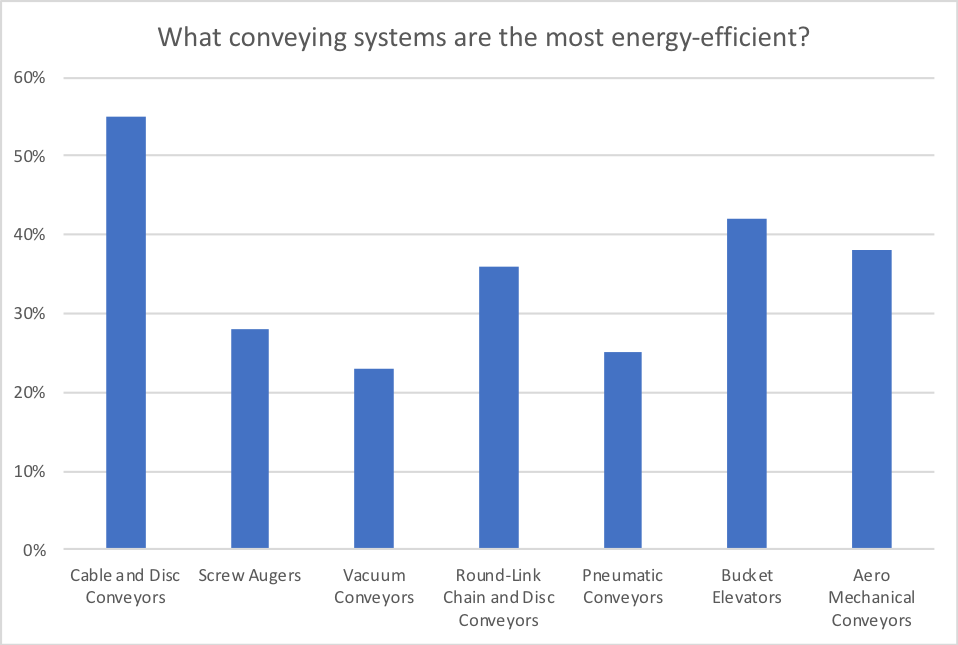

What factors influence energy efficiency? The motor’s size and the horsepower needed to operate a conveyor system can significantly affect operational expenses. Which conveyor system offers the best energy efficiency for coffee handling? By a notable lead, cable and disc conveyors top the list at 55%.

Two Questions for Determining the Right Equipment

Here are a couple of questions to consider about energy and efficiency:

- What’s the system’s power consumption level?

- At what point does this system’s efficiency begin to decrease or increase?

The Final Verdict Is That Tubular Conveying Systems Reign Supreme

The coffee sector is expanding and undergoing changes. This study offers a glimpse into how experts in the field are gearing up for this expansion and making informed choices for their operations.

The study indicates that cable and disc conveyors stand out as the top choice for coffee establishments. Tubular conveyor systems enhance the coffee processing workflow and ensure the consistency and quality of whole coffee beans, ground variants, and soluble coffee powder.

To find out if Cablevey Conveyors offers ideal conveyor solutions for your coffee beans, contact us and have the Cablevey Testing Center perform a free test for you. The data will be provided by our Testing Center to help you make a sound decision for specific production requirements. We have only covered a portion of the findings from the research study done by Ascend2. We recommend downloading Evaluating and Implementing New Conveyor Systems for more insight into the food processing industry.