Hearing all those positive things about a tubular conveyor has many thinking about all the benefits it can bring. However, it’s crucial to consider how minimizing cleaning and maintenance issues with a tube conveyor system can help you boost your production even more. This blog post explores the issues around cleaning and maintaining conveyor equipment and some tips for making these processes easier.

Why Is Minimizing Cleaning and Maintenance Issues With a Tube Conveyor System Important?

According to research conducted by Cablevey Conveyors in partnership with Ascend2, 54% of industrial businesses view cleaning and maintenance as their number one challenge when conveying materials. But why is this the case?

There are a few reasons. Different types of conveyor technologies can be designed in ways that make them difficult to clean. They could have many nooks and crannies where contaminants can become trapped. They may also require frequent disassembly for cleaning, sanitizing, and maintenance, which can lead to downtime and lost production.

While cleaning and maintenance can’t (and should not!) be avoided, there are ways to minimize the frequency and duration of these activities and still adhere to all industry standards regarding the cleanliness and safety of your conveying system.

Common Cleaning Issues With Automatic Conveyor System

Our research shows that, when looking to purchase new industrial conveyor systems, the top two considerations for decision-makers are how easy to clean the system is and whether or not it is energy efficient.

The ease of cleaning is especially important for the food processing industry, where ensuring all automated conveyor systems are free of contaminants is critical for health and safety. A speck of dust, food residue, debris, or any other substance can cause big problems in food processing. It can contaminate the product, which can lead to recalls and decreased profits further down the line.

Thanks to DNA mapping, tracing microbial contamination to its source has become much easier in recent years, meaning that food processors can no longer afford to have any contaminants in their facilities. The most common cleaning system issues that food processors face include:

- Conveyor nooks and crannies where contaminants can accumulate,

- Inability to clean the entire conveyor system in a short amount of time,

- Requiring frequent disassembly for cleaning, which can lead to downtime,

- Cleaning and sanitation of chemical residue buildup,

- Dust explosion risk.

Critical Considerations in Conveyor Manufacturing: Ensuring Ease of Cleaning and Maintenance

Conveyor manufacturing is a specific process, and you have to be prepared to put some effort into maintaining your systems. Otherwise, you’ll end up with some irreparable damage. Luckily, there are three key factors to take into account when determining whether a system is easy to clean or not:

Conveyor Material

In the food processing industry, conveyors need to be made from materials that can resist corrosion and microbial growth and withstand frequent cleaning and sanitizing with harsh chemicals. The most common material used in food conveyors is stainless steel.

However, special attention should also be paid to the material of the surface that comes in direct contact with the food material, such as belts, pans, tubes, etc. These surfaces need to be smooth and non-porous so that they can be easily cleaned and sanitized. Both the choice of material and its finish must comply with the requirements of the food safety regulations in your jurisdiction.

Conveyor Design

The design of the conveyor solutions can have a big impact on how easy it is to clean. A sanitary conveyor that is easy to clean needs to have as few locations as possible where food residue can accumulate.

Its frames should be welded and rounded, and the “food zone” of the conveyor should have a minimal number of fasteners. All of this will help to reduce the number of corners and tight spaces where contaminants can hide.

Motors and Connections

One may think that the conveyor motor(s) location is irrelevant. However, if they are located in an inaccessible place, it can make cleaning the system a lot more difficult. Moreover, enclosed motors, such as drum and gear motors, can stand up to washdowns much better than exposed motors.

The conveyor connections (from the motor to the material handling parts) have to be configured in such a way that they can be easily disconnected for cleaning purposes without the need for special tools. This will make it easier to disassemble the conveyor and put it back together once the cleaning is done.

Explore the Possible Maintenance Issues When Manufacturing Conveyor Systems

Regular conveyor maintenance is essential for ensuring that the system runs smoothly without unexpected problems, breakdowns, or delays. In addition to cleaning, it is important to carry out regular maintenance tasks such as lubricating bearings, checking for belt damage, chain or cable wear and alignment, and tightening fasteners.

Even though maintenance is crucial in keeping the conveyor system in good condition, due to its time-consuming and tedious nature, it represents the biggest challenge for food processors. In fact, 64% of decision-makers in food processing facilities state that one of the top reasons for updating their conveying processes is maintenance issues. This being said, here are some of the most common problems with maintenance that food processors face:

- Difficulty in accessing certain parts of the system for maintenance,

- Downtime due to frequent maintenance requirements,

- Lack of knowledge among employees on how to carry out maintenance tasks,

- No access to the right tools and replacement parts.

Optimize the Conveyor Maintenance – Strategies for Efficiency and Reliability

Some of these issues could be minimized with better maintenance processes, such as scheduled maintenance checks, proper training for employees, having a well-stocked parts inventory, and keeping maintenance logs that document the work that has been done.

At the same time, the conveyor system itself needs to be designed for easy maintenance. For instance, if the conveyor doesn’t have to be disassembled completely to be repaired, it will save a lot of time and effort.

Nowadays, modern conveyors have parts that can be removed without tools so that maintenance workers can easily access and replace them. Depending on the material you are transporting in your food processing facilities, you might be able to solve a lot of the cleaning and maintenance issues we outlined here by investing in a tube conveyor.

How a Revolutionizing Tube Conveyor Helps the Cleaning Process?

A tube conveyor, a modern and efficient alternative to a traditional conveyor belt system, securely transports products within a specially designed tube, eliminating the risk of material spillage. Among the various conveyor systems manufacturers, Cablevey’s tubular drag cable and disc conveyor systems are particularly advantageous for conveying materials such as:

Traditional Belt vs. Modern Tubular Conveyors

Unlike the traditional belt conveyor system, Cablevey’s tubular conveying system has circular discs strategically spaced along a sealed cable. That way, the product is gently guided through a tube. This innovative design minimizes the likelihood of spillage and enhances the cleanliness of the conveying process. Now, let’s explore how these tube conveyor systems address and alleviate the common cleaning and maintenance challenges faced by food processors.

Wet and Dry Cleaning

A tubular drag conveyor can be outfitted with both wet and dry cleaning options. The wet cleaning option utilizes a washdown system that sprays water, foam agents, and sanitizing agents into the tube. The dirty water and chemicals are then drained away, so there is no need for employees to come into contact with them.

Although it’s an automated conveyor system that requires little to no operator intervention, most food processors shy away from wet cleaning because it requires an added step of drying the tube before it can be used again.

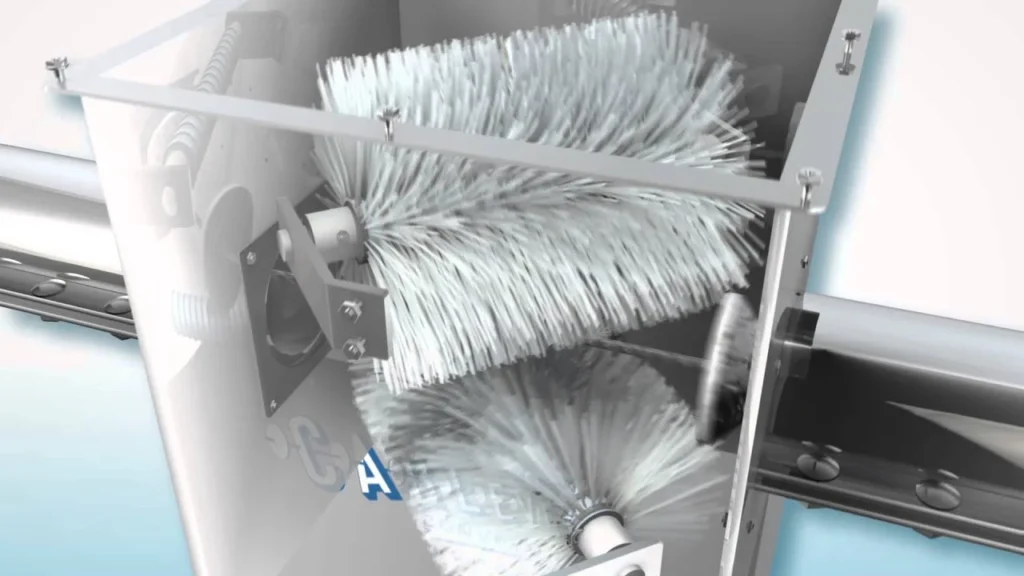

Dry cleaning, on the other hand, is a lot less time-consuming. Cablevey has a dry cleaning method that includes a urethane disc that is dragged through the tube after each run or product change. An additional advantage to this urethane disc is that it collects fine material, such as coating powder and spices, that may have been left behind in the tube, making them available for reuse later on.

Clean-In-Place

Clean-in-place (CIP) methods are a great way to clean your conveyor system without having to take it apart. They involve circulating cleaning solutions and devices through the system and can be used for both wet and dry cleaning. However, be aware that there are more traditional methods for cleaning conveyor belts, too.

CIP methods are typically used in food and beverage processing because they minimize the amount of time the production line is taken offline for cleaning. As a result, there is less chance of cross-contamination and product loss. Tube conveyors are the perfect solution for CIP because they are designed with many inlets and outlets that allow the cleaning solutions to reach all areas of the system.

Pneumatic Tensioning

All cable, chain, and belt conveyor manufacturers have to think about maintaining the tension. It is a vital aspect of conveyor system upkeep. Traditional methods of tensioning, often associated with conveyor belt systems, can prove to be both time-consuming and hazardous.

However, advancements in conveyor technology offer a safer and more efficient alternative – pneumatic tensioning. This innovative approach utilizes compressed air to precisely apply the required tension to the conveyor’s rope, chain, or cable.

Unlike traditional methods that might involve risky manual adjustments, pneumatic tensioning eliminates the need for employees to be close to the conveyor during operation. This advanced tensioning system, available as an option on all Cablevey Conveyors, empowers employees to simply turn a knob to achieve the desired tension, streamlining the maintenance process for belt conveyor systems.

With Cablevey Conveyors, Cleaning and Maintenance Will Be a Breeze

What food processors struggle with the most in terms of conveyor systems is the amount of time it takes to clean and maintain them. These processes are vital for keeping the conveyor running smoothly and preventing cross-contamination but can cause significant downtime, loss of productivity, and, ultimately, loss of profit.

Tube conveyors help to minimize these struggles by providing a number of different cleaning options as well as maintenance features such as pneumatic tensioning. They are also designed for clean-in-place (CIP) methods so that all areas of the system can be easily cleaned without having to take the conveyor apart.

If you are looking for a conveyor system that will help you save time and money on cleaning and maintenance, a tube conveyor is the perfect solution. Contact Cablevey Conveyors today to learn more about our conveying solutions and how they can benefit your food processing facility.