The snack food industry trends for 2023 highlight a dynamic shift towards healthier, more sustainable, and innovative eating options. As consumers increasingly prioritize nutritional content, environmental impact, and novel flavors, manufacturers are responding with a range of products that cater to these demands. From plant-based alternatives to eco-friendly packaging and exotic taste profiles, the upcoming trends are set to redefine snack consumption.

What Are the Top Snack Food Industry Trends for 2023?

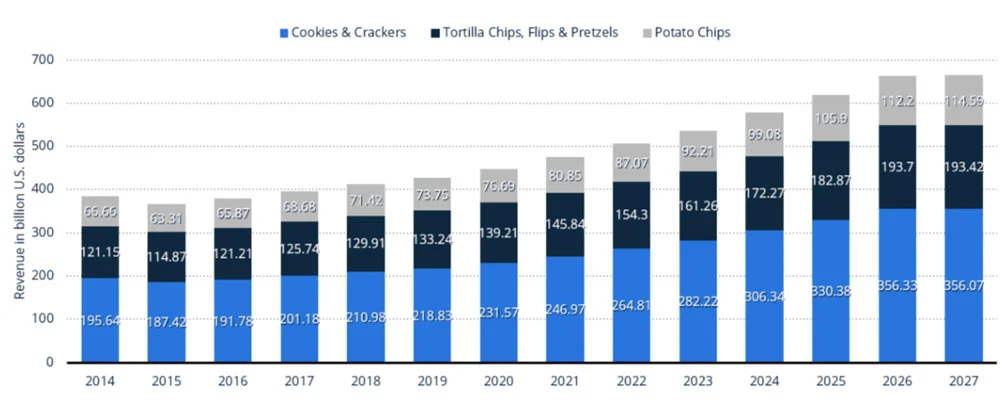

The snack food industry continues to grow, with worldwide sales in 2022 at US $506 billion – and the projections for 2023 are $535 billion, according to Statista. Is your facility ready for the growth of the snack food industry and all the changes in production that come with it?

Cablevey Conveyors initiated a study in October 2022 through Ascend2, an independent research firm. The study, named Evaluating and Implementing New Conveyor Systems, involved 290 food processing experts from the US and the UK. They shared insights on what to consider when selecting industrial conveyor systems. This article will focus on responses from 177 professionals working with snack foods, exploring their preparations for anticipated growth.

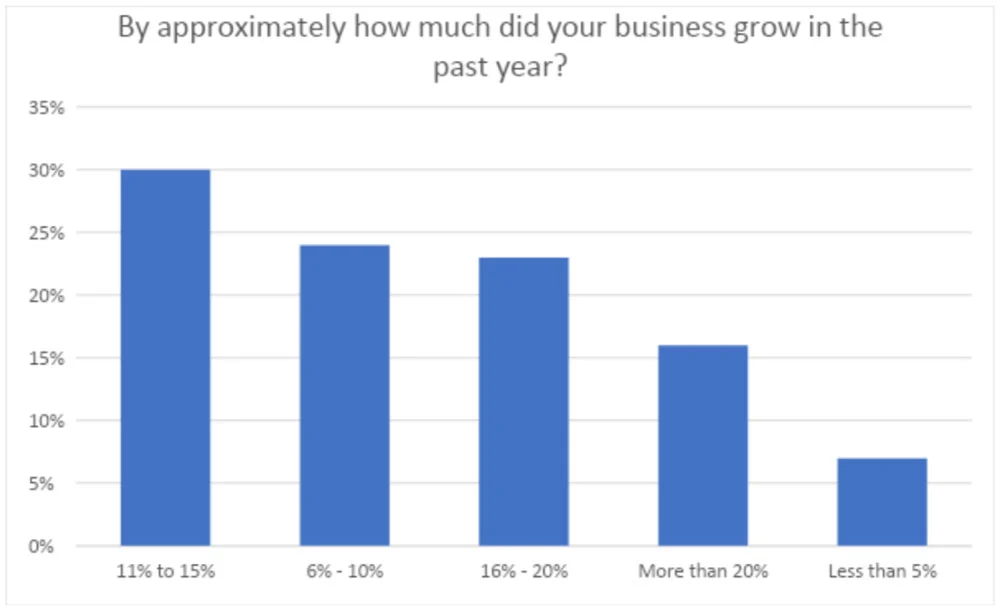

Finding #1: Budgeting for Growth

A significant 85% of snack food processing facilities plan to boost their budget for conveyor equipment and maintenance over the next year. Of these, 33% anticipate a substantial budget increase to capitalize on growth opportunities. This budget rise is a reaction to their business expansion over the previous year.

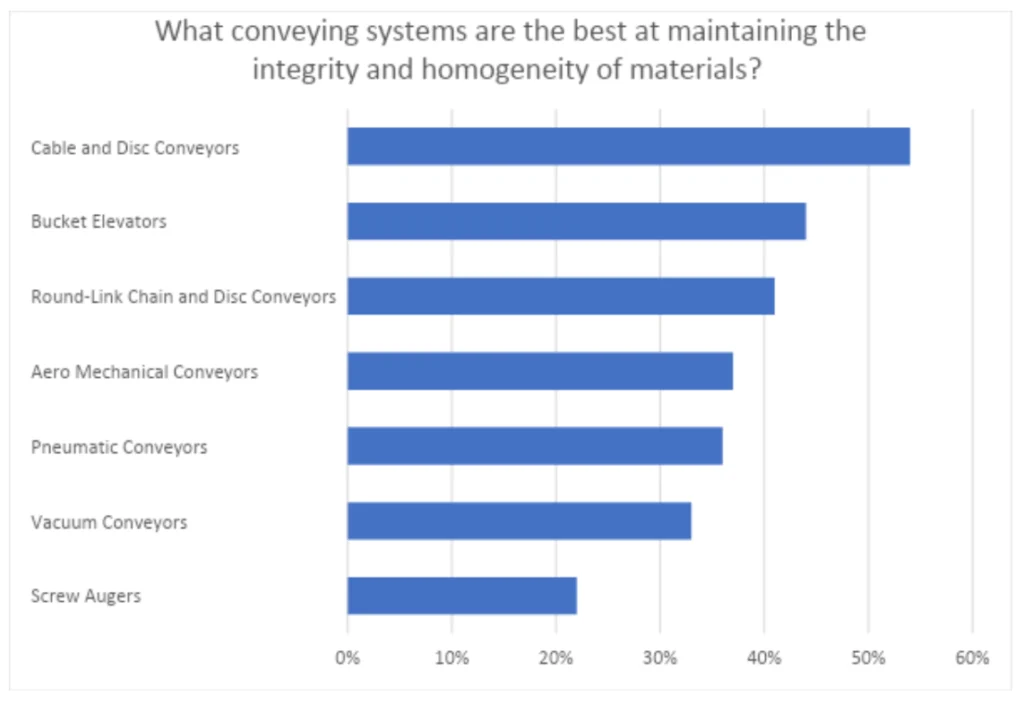

Finding #2: The Best Solution to Maintain the Integrity of Snack Foods While Conveying

To cut down on waste and loss, it’s important to move delicate snack foods carefully. Whether they’re sold by themselves or in a mix, you need to handle and move them gently to keep them from breaking. What system ranks #1 by the snack food industry professionals for maintaining the integrity of snack foods? Tubular cable and disc conveyors are first at 54%. When evaluating a conveying system for product integrity, here are two questions to ask.

Will the system maximize hygiene levels while minimizing downtime? Will the system gently convey your products to avoid material breakage and product loss? In the case of tubular conveyor systems, the answer to both of these questions is yes.

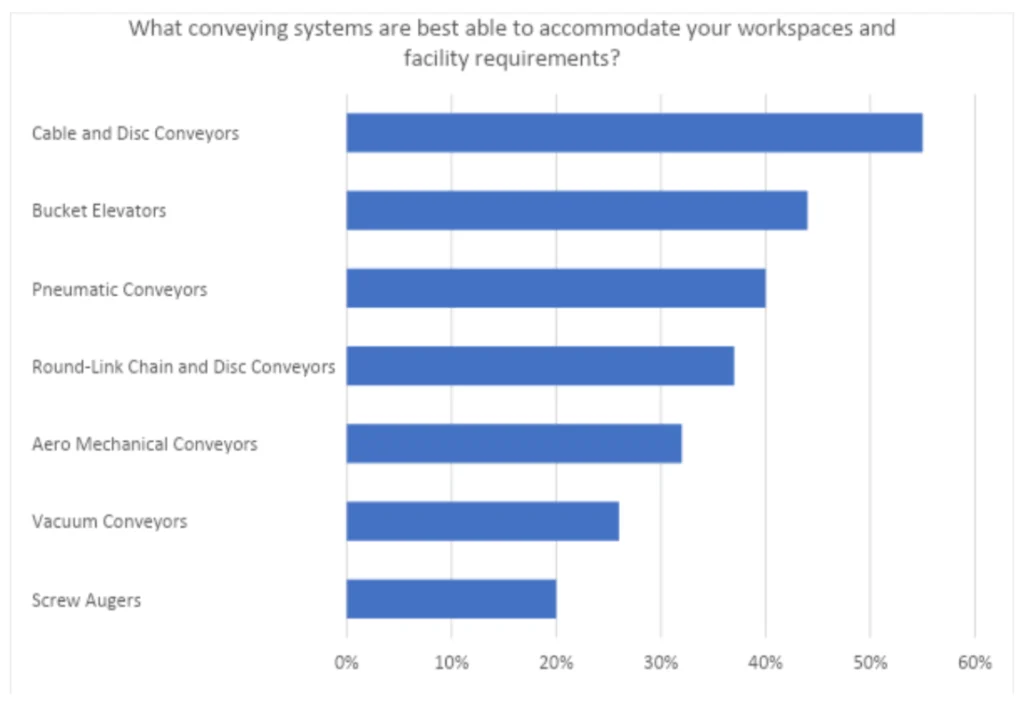

Finding #3: Workspaces Facilitating the Need for Growth

When thinking about growth, consider the space and needs of your facility. What type of conveyor fits your available space best? Surveyed snack food experts say the top choice for saving space is the tubular cable and disk conveyor, chosen by 55% and leading the second-place bucket elevators by 11%. Bucket elevators come in second due to their flexibility with workspace needs. Here is a short video that shows the benefits of a cable and disk conveyor system vs. a bucket conveyor system:

When picking a conveyor system to make the most of your space, ask yourself a few questions. Do you have the floor or ceiling space for specific conveyors? Does the conveyor layout allow for easy cleaning, maintenance, worker safety, and good performance? When it comes to tubular conveyor systems, you won’t have to worry about these issues.

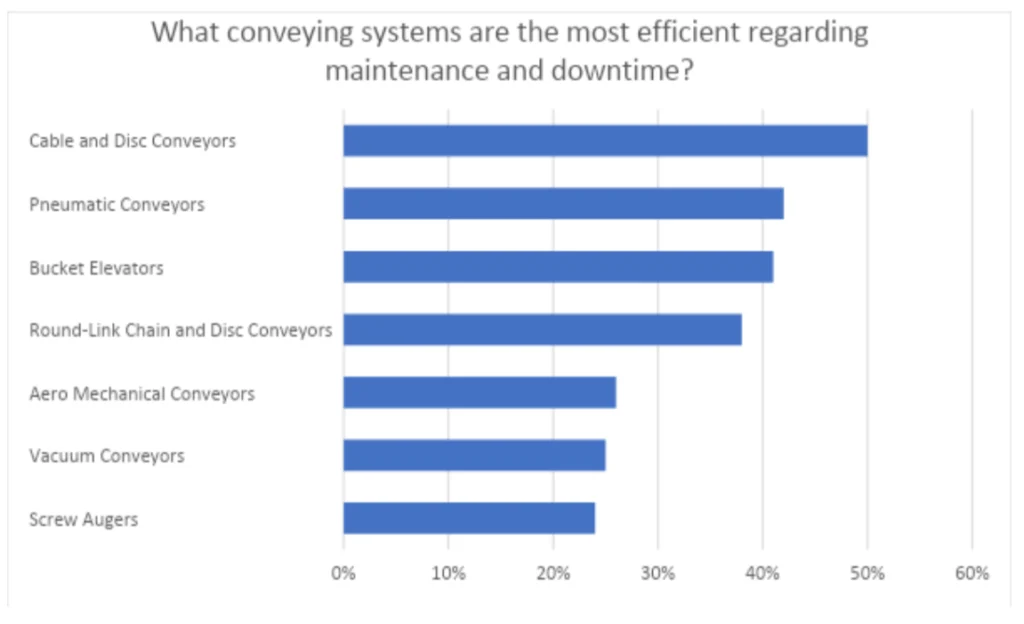

Finding #4: Considering Maintenance and Downtime

When evaluating the right conveyor system for the snack food processing industry, it’s essential to consider maintenance and downtime critically. Here are the main questions you should ask when evaluating the right conveyor system:

- How much time will you need to disassemble and clean the conveyor?

- What are the expected maintenance intervals, and how complex are the procedures?

- Will downtime and maintenance cost you more than initial savings from the system’s purchase?

Additionally, assess the availability of replacement parts and the system’s overall durability. Rather than becoming a financial burden due to frequent maintenance needs and operational interruptions, understanding these factors can help prevent prolonged downtime. This ensures the system contributes positively to operational efficiency and cost-effectiveness.

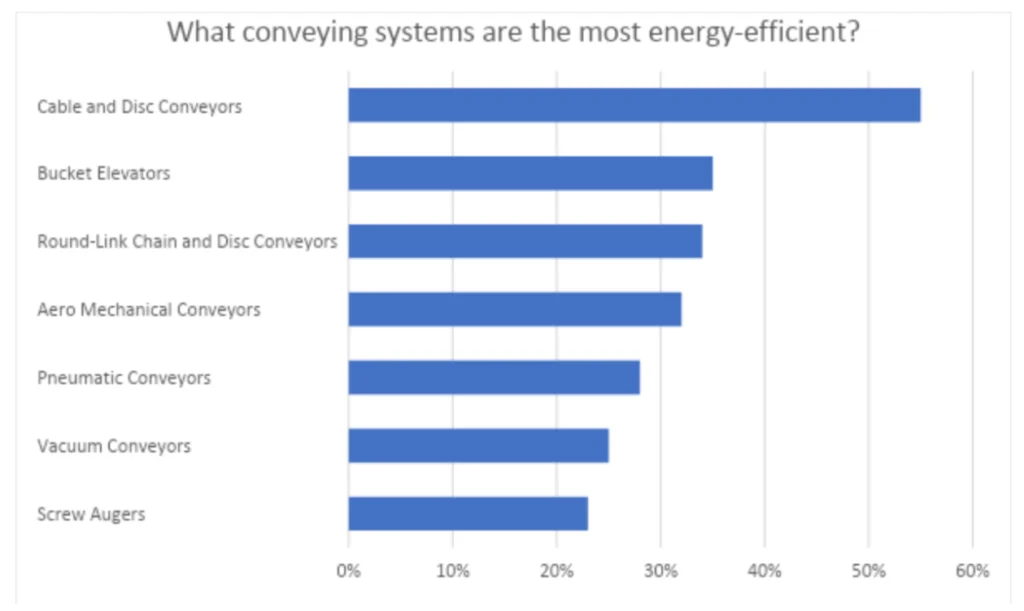

Finding #5: Considering Energy Efficiency of Conveyor Engineering

What affects energy efficiency? The motor size and the horsepower needed to operate a conveyor system greatly influence production expenses. Which conveyors are best for energy savings with snack foods? Cable and disc conveyors lead at 55%. When selecting your new conveyor system, consider these questions about energy and efficiency:

- How much energy will the system consume?

- At what point does the system’s efficiency drop, whether at high or low usage levels?

Learn More About Snack Food Industry Trends in Cablevey’s Extensive Research

The snack food sector is on the rise, adapting to new challenges. This study sheds light on how experts in the field are gearing up for expansion and choosing the right equipment for their operations. It highlights cable and disc conveyors as the top choice for handling snack foods. These tubular conveyor systems streamline food processing while preserving the quality, nutritional balance, integrity, and appealing characteristics of snack products.

To determine whether a Cablevey system fits your snack food conveying needs, you can get a complimentary test from the Cablevey Testing Center. We’ll give you detailed data to ensure you make a well-informed decision tailored to your requirements. This summary touches on just a few insights from the Ascend2 research. For a deeper dive into food processing trends, you can download the full Evaluating and Implementing New Conveyor Systems study.

Contact Cablevey Conveyors for Conveyor Solutions of the Highest Quality

Elevate your production efficiency with Cablevey Conveyors, the leading provider of high-quality conveyor solutions tailored to meet the unique needs of your operation. Specializing in gentle handling and hygienic transportation of materials, our conveyor technologies ensure your products are moved efficiently and safely, preserving their integrity.

Our team of experts is committed to delivering innovative solutions that optimize productivity, minimize downtime, and comply with industry standards. Contact us today to discover how our state-of-the-art conveyor engineering can transform your processing environment, enhancing your operational capabilities and ensuring superior results.

FAQ

What Are the Key Trends in the Snack Food Industry for 2023?

The snack food industry in 2023 is moving towards healthier options, sustainability, and unique flavors. Consumers are seeking nutritional content, environmental responsibility, and innovative taste experiences, driving manufacturers to adapt their product lines accordingly.

How Are Snack Food Processing Facilities Preparing for Industry Growth?

85% of snack food processing facilities are increasing their budget for conveying equipment and maintenance to meet growth opportunities. This is in response to significant industry growth and the need to maintain product integrity during conveyance.

Why Are Tubular Cable and Disc Conveyors Preferred for Snack Foods?

Tubular cable and disc conveyors are the top choices for maintaining the integrity of snack foods. They offer maximum hygiene, minimize downtime, and gently convey products to avoid material breakage and product loss.

What Considerations Are Important for Workspace and Facility Growth in the Snack Food Industry?

Facilities must consider space optimization and the ability of conveyor systems to fit into available space while ensuring easy access for cleaning, maintenance, safety, and operational efficiency. Tubular conveyor systems are highly recommended for these requirements.

How Does Energy Efficiency Impact the Choice of Conveyor Systems for Snack Foods?

Energy efficiency is crucial due to the impact of motor size and horsepower on production costs. Cable and disc conveyors are highlighted for their energy efficiency, making them a cost-effective choice for snack food processing.