Tubular drag conveyors are an excellent option for transferring bulk material. They are used in the food processing industry for handling fragile material products such as pet food, breakfast cereals, nuts, various snack foods, frozen foods, and more. But do we know how tubular drag conveyors compare to other conveyor types? If you’re curious about the answer to this question, keep reading for a detailed comparison with other types of conveyor systems.

How Tubular Drag Conveyors Compare to Other Conveyor Types and Are They a Superior Choice for Your Conveying Needs?

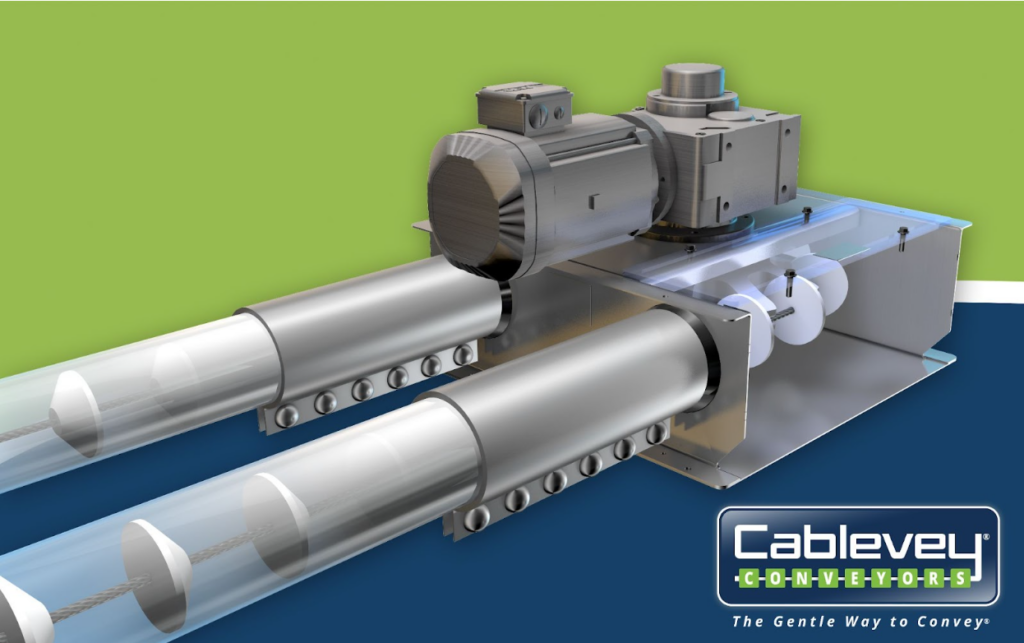

Tubular drag conveyors are a type of enclosed conveying system used as bulk material handling equipment. They utilize a chain or cable to drag or pull a series of disc-shaped flights through a tubular pipeline, efficiently and gently moving materials from one location to another.

The enclosed nature of this system minimizes product exposure to external contaminants and reduces dust generation. Ideal for fragile or specialty materials, these conveyors offer precise control over conveying speed, ensuring minimal product degradation while maximizing safety and minimizing cleanliness issues.

Compared to other types of conveyor systems, tubular drag conveyors have several advantages, including ensuring a dust-free environment (reducing the risk of a dust explosion) and preventing foreign contamination of the product. They are also relatively easy to maintain and clean regularly. In the section below, we will talk about how this conveyor equipment compares to other commonly used conveying systems.

Tubular Drag Conveyors vs. Screw Augers

Auger conveyors (or screw conveyors) are similar to tubular drag systems in that they also convey materials through a tube. They utilize an auger inside the tube, which is a rotating, helical corkscrew-like blade that pushes granular or liquid materials forward. Auger systems reduce noise just like tubular drag solutions.

Screw Augers Aren’t Suitable for Gentle Materials

Unfortunately, screw augers are not the best choice for conveying fragile materials, especially blended ones. This is simply because the auger blade rotates directly through the material, causing material breakage, grinding, and blend separation. This screw design is why auger conveyors are mainly used for semi-solid materials such as boiler ash, meat, animal feed, aggregates, food waste, municipal solid waste, and similar.

If you need to transport materials that require gentle conveying, a tubular conveyor is a much better option. When it comes to facility requirements, screw augers are not as flexible as tubular drag systems. Even though they are known as “flexible screw conveyors,” because of the upward design and motion of the screw, using these conveyors in multiple planes is limited. The higher the incline on the screw conveyor, the more power it will use – in contrast, tubular drag conveyors are quite efficient.

Tubular Drag Conveyors vs. Aero-Mechanical Conveyors

Another tube type of conveyor, aero-mechanical systems, comprises a steel tube with a circulating rope that passes through it. Discs are evenly spaced along this rope, similar to how discs are positioned in a tubular chain or cable drag conveyor.

These discs create an airstream as they move at very high speeds inside the tube. This leads to significant product and material breakage at bends. If you want to convey fragile materials with this system, you need to maintain a slow and steady speed. Tubular drag conveyors are much more suitable for this application.

Aero-Mechanical Conveyors Have an Additional Step in the Maintenance Process

The aero-mechanical and tubular conveyor solutions are both flexible and can fit almost any floor space size and layout. They are also both relatively efficient and don’t require high energy expenses. That being said, because of the rope in their design, aero-mechanical conveyors require rope-tensioning. This adds another step in the maintenance process, increasing cost and downtime. Other than that, aero-mechanical solutions are not too difficult to keep clean.

Tubular Drag Conveyors vs. Pneumatic Conveyors

There are two types of pneumatic conveyor systems – vacuum conveyors and air-pressure conveyors. The former utilizes negative conditions (a vacuum), and the latter utilizes positive conditions (air pressure) to move dry bulk materials through a fully enclosed line (a tube). Different food products and materials can be transported via pneumatic conveyors, similar to tubular drag conveyors. Typically, pneumatic conveyor systems are used for:

- Metal powders,

- Sands,

- Coal fines,

- Food products,

- Wheat flour,

- Sugar,

- Starch.

Like tubular drag conveyors, pneumatic solutions are flexible and can accommodate various spaces. They can even cover long distances if need be, though air-pressure conveyors are better at this than vacuum ones. However, a problem with pneumatic conveyors occurs when it comes to product integrity – they are known to damage delicate materials.

Additionally, filters are required for dust containment and control. These filters need regular changing. Furthermore, pneumatic systems need a lot of electrical power to maintain the vacuum or air pressure. They spend up to 10 times more energy than cable conveying systems. A pneumatic vacuum conveyor also generates considerable noise.

Tubular Drag Conveyors vs. Bucket Elevators

Unlike the previously mentioned systems, bucket elevators are not equipped with a tube. Instead, they have multi-sided containers (buckets) that move material either vertically or horizontally. A belt carries these buckets, with a power source driving the belt. Bucket elevators are great for transporting flowable bulk materials, such as fertilizer or grain.

However, bucket elevators are challenging to clean. A wide variety of moving parts (bolts, nuts, buckets, etc.) means that their maintenance costs are much higher than for tubular drag conveyors. On the other hand, bucket conveyors reduce noise, are energy-efficient, and don’t require a lot of driving power. That being said, they are typically not suitable for industries where sanitation and product safety (such as food safety) are important.

Tubular Drag Conveyors vs. Belt Conveyor Systems

The distinct differences between the belt conveyor system and the tubular drag conveyor are obvious at first glance. However, given that a conveyor belt system is one of the most common conveying systems on the market, it is also worth mentioning.

These solutions consist of pulleys (two or more) that move a closed loop of material (the belt) by rotating. The pulleys are usually powered by a motor that drives the belt in the right direction. Two types of belt conveyors are used: for transporting general materials (solid items, packaging, and boxes) and for transporting bulk products and materials. Even though most belt conveyors are open, they can also be enclosed to lower the chances of ambient contamination and loss of material.

Industrial Conveyor Belt for Food Isn’t Suitable for Limited Spaces

Belt conveyors are used in a wide range of industries. However, they are a terrible choice for vertical material conveying. If you are looking at limited floor space and steep angles, a simple belt conveyor – even an enclosed one – just won’t do. Furthermore, belt systems require a high initial investment and need to be carefully set up for reliable operation. When it comes to conveying food materials and products, there are better choices than belt conveyors.

Chain vs. Cable Tubular Drag Conveyors – What’s the Difference?

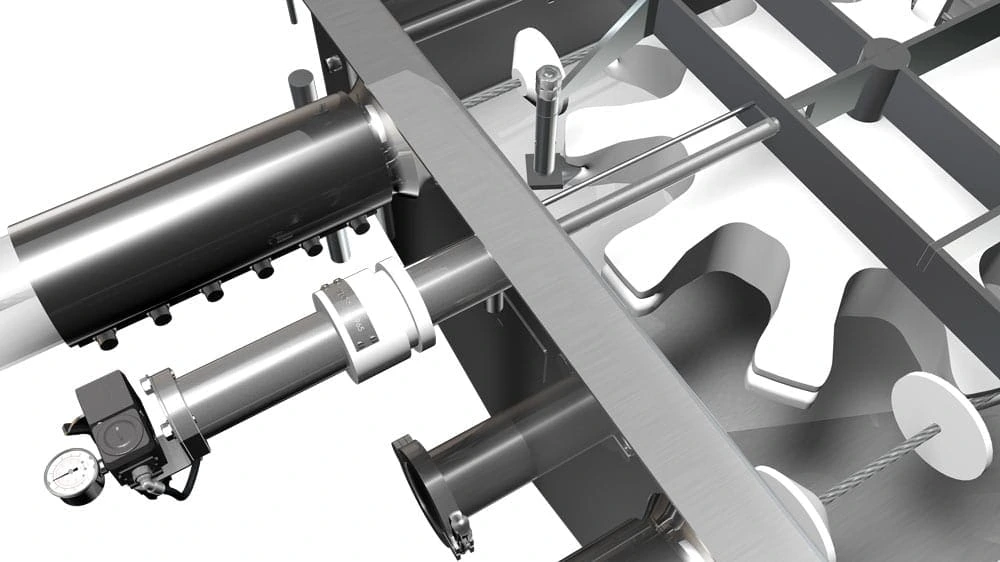

It is important to mention the differences between the two primary types of tubular drag conveyors as well. Not all tubular drag conveyors are the same – drag cable and drag chain systems come with different maintenance and cleaning requirements and different energy costs.

Tubular Chain Conveyors

Tubular chain drag conveyors can compromise product integrity. They are also not the most sanitary option because food particles collect in the exposed chain, becoming a breeding ground for bacteria. Drag chain conveyors have some routing restrictions and are not as flexible as cable conveyors. They are difficult to clean, and their sprockets need frequent replacement. They also require more energy to operate compared to cable drag conveyors.

Tubular Cable Conveyors

Cable conveyors are fully optimized systems for the food processing industry. The stainless steel cable inside their tubing doesn’t collect any debris or food particles – it is sealed in a nylon jacket, making it smooth and not in direct contact with the transported material. Unlike a chain one, a drag cable conveyor can move products in all directions – horizontally, vertically, at angles, and even around corners.

These systems have fewer moving conveyor components than chain systems and are thus easier to maintain. Cable systems also have more mechanism cleaning options than chain conveyors. Finally, cable drag conveyors don’t need much horsepower to run, meaning their energy costs are lower than those of chain drag conveyors.

How to Choose the Right Conveyor System?

How to decide which conveying system is the best option for your facility? Do you need a simple custom conveyor belt for a warehouse or a tubular conveyor? Determining what materials handling equipment is the best for your business depends on a series of factors:

- The material type you want to convey (particle size, flowability, stickiness, and whether they are raw materials),

- Your floor size and layout,

- How big your budget is (both for initial investment and for maintenance cost considerations),

- Industry requirements (any special food safety or sanitation standards and similar),

- Throughput requirements.

Are You Looking for a New Conveyor System? Contact Cablevey Conveyors for More Information

Choosing the right material handling solution for your production facilities is a big decision. In this blog post, we’ve outlined all the basics you need to know about the most common conveying systems. If you have any questions about these systems or are not sure which one would suit your facility the most, don’t hesitate to contact us – Cablevey Conveyors is here to help you. We’re looking forward to hearing from you!

FAQ

What Are Tubular Drag Conveyors?

Tubular drag conveyors are enclosed systems used for bulk material handling. They utilize a chain or cable to pull disc-shaped flights through a tubular pipeline, moving materials gently and efficiently. These conveyors reduce exposure to contaminants, decrease dust, and offer precise speed control, making them ideal for fragile materials.

How Do Tubular Drag Conveyors Differ From Screw Augers?

While both move materials through a tube, screw augers use a rotating blade which can damage fragile items. In contrast, tubular drag conveyors use chains or cables, preserving material integrity. Additionally, screw augers are less flexible in terms of installation angles and consume more power on inclines compared to tubular drag conveyors.

How Do Aero-Mechanical Conveyors Compare to Tubular Drag Conveyors?

Both types of systems can fit into various floor spaces, but aero-mechanical conveyors operate with a rope carrying discs at high speeds, causing material breakage at bends. Aero-mechanical conveyors also need rope-tensioning, adding to maintenance time and costs. Tubular drag conveyors, in comparison, are gentler on materials and require less complex maintenance.

What Are the Pros and Cons of Pneumatic Conveyors?

Pneumatic conveyors, which use vacuum or air pressure, can move a range of materials and cover long distances. However, they can damage delicate items, need filters for dust control, and consume significantly more electricity than other conveyor systems. They can also be noisy, especially vacuum conveyors.

How Do Bucket Elevators Differ From Tubular Drag Conveyors?

Bucket elevators move materials using containers (buckets) on a belt, whereas tubular drag conveyors use a tube. Bucket elevators are hard to clean, have higher maintenance costs, and aren’t ideal for industries prioritizing sanitation. In contrast, tubular drag conveyors are more efficient and hygienic.

Why Might Belt Conveyor Systems Not Be Suitable for Some Applications?

While commonly used, belt conveyors aren’t good for vertical material transportation, especially in limited spaces. They also require a high initial investment and careful setup. For conveying food, there are often better options due to concerns about space and sanitation.

What’s the Difference Between Chain and Cable Tubular Drag Conveyors?

Chain conveyors can compromise product integrity and aren’t as hygienic, with food particles accumulating in chains. They have routing restrictions, need frequent sprocket replacements, and use more energy. Cable conveyors are better for food processing, move in all directions, require less maintenance, and are more energy-efficient.

How Should One Choose the Right Conveyor System?

Consider the material type, floor size, budget, industry requirements, and throughput needs. Factors like particle size, flowability, safety standards, and initial setup and maintenance costs will influence the best choice for your facility.

Why Are Tubular Drag Conveyors Recommended for Fragile Items?

Their enclosed design and gentle dragging mechanism ensure that products like cereals, nuts, and snacks are not broken or degraded during transport. They offer precise speed control and reduce exposure to external contaminants, ensuring product safety and integrity.

Who Can I Contact for More Information on Conveyor Systems?

You can reach out to Cablevey Conveyors for expert advice and more information. The company has experts who can provide insights on various conveyor systems and help you select the right material handling solution for your needs.