Navigating the myriad options in the world of industrial conveyor systems is a crucial undertaking for any food processing plant. The choice you make can have far-reaching consequences, so you’ll need some of the best tips for choosing the right conveyor system. Not only will it impact your efficiency but also your entire manufacturing. Here are some of the most important considerations when choosing between conveyor solutions.

What Are Some Good Tips for Choosing The Right Conveyor System?

Selecting the right solution among many conveyor technologies involves considering key factors such as product specifications, available space, energy efficiency, and maintenance requirements. Understanding your material’s characteristics, optimizing layout, and aligning with business goals are essential tips for making an informed decision.

However, choosing the right conveyor system can be a difficult task. Making the wrong decision could cost you in terms of money, time, and efficiency. So, to make a selection among the many conveyor systems manufacturers, you’ll need to understand the different conveyor types. This includes learning which material handling system designs are most compatible with your operations.

Common Conveyor Types in the Food Industry

There are dozens of conveyor types to choose from. The most commonly used conveyor in the food industry is a tubular conveyor. However, we must mention other other options as well:

- Bucket elevators,

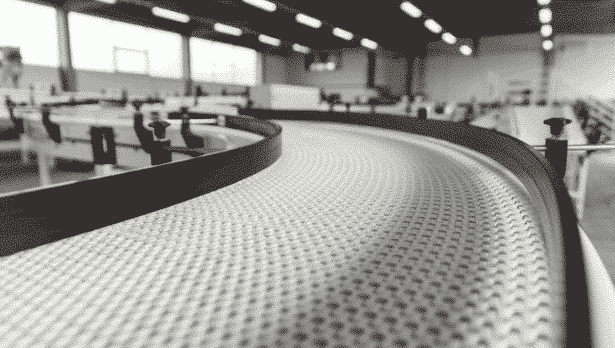

- Conveyor belt systems,

- Roller conveyors,

- Vacuum conveyors,

- Pneumatic conveyors,

- Screw conveyors,

- Aero-mechanical conveyors.

Key Factors to Consider When Selecting a Conveyor Type

When considering the proper selection of a conveyor for your facility, key factors come into play. The most important step here is to recognize the unique demands of your product and operations and how they will ultimately impact your choice of a conveyor system. Evaluate the specific requirements of your product, including its type, length, height, and width, as well as weight.

Take into account characteristics such as high moisture content, explosiveness, or fragility, necessitating a gentle handling approach. In this context, a tubular conveying system emerges as a favorable option for their gentle material handling. Additionally, prioritize the cleanliness aspect by considering cleaning conveyor belts, especially in food processing environments where hygiene is crucial.

Check Out the Product Specifications

Before deciding on a conveyor, consider your product’s type, length, height, and width. Product weight also plays a significant role because it determines the size of the conveyor motor required. To do that, you can ask yourself some of the following questions:

- How bulky is the conveyed material?

- Does it have characteristics that require it to be handled differently, such as high moisture content or explosiveness?

- Is it flammable?

- Does the material need to be conveyed gently because it is extremely fragile?

- Does the material have traits like corrosiveness and abrasiveness? Does it need to maintain a specific temperature?

Choose the Conveying System in the Base of Your Product Handling

Some conveyor systems aren’t built to handle certain materials gently. If you need to convey fragile materials, such as nuts, breakfast cereals, or coffee, you need to avoid conveyors that may lead to material breakage and product loss.

For example, equipment like aeromechanical, belt, pneumatic, vacuum, and bucket elevator conveyors may force fragile materials through stressful phases during transport that could impact their integrity.

Bucket elevators are also not ideal for high-moisture materials that may end up sticking and drying on the bottom and sides of the bucket. Cleaning dried material from bucket elevators becomes a nightmare and costs you time and money. It also makes maintaining a sanitary environment that complies with food safety regulations more challenging.

Screw conveyors, also known as auger conveyors, tend to be rough on materials like nuts and end up grounding fragile nuts into pieces, resulting in costly wastage. Compared to these options, tubular cable and disc conveyors are gentler on your product and make long-term use a more attractive option.

Ensure the Layout and Available Space Are Just Right

Conveyor manufacturing was never about making just one machine that would be compatible with all processing needs. That’s why sometimes the choice of conveyors is influenced by the available space for installing material handling systems. Constraints in floor space or ceiling height may limit the feasibility of certain conveyor types.

However, some conveyors, like tubular drag conveyors, are highly customizable and can be designed to maximize available space. The conveyor system design can be laid out depending on production flows, incline or decline, and product transfer requirements. It can also include corner sections and make use of overhead space.

Keep in mind that when planning the production line layout, it is crucial to consider accessibility for cleaning and maintenance, ensuring worker safety, and enhancing operational performance. Optimal system designs prioritize production flows to enhance efficiency and productivity.

Count in the Factor of Energy Efficiency When Looking at Different Manufacturing Conveyor Systems

Nowadays, saving as much energy as possible during production is a must. That being said, there are some questions you’ll need to answer and find the most suitable system for your processing needs.

- Have you considered how much energy your new system will use?

- Is there a high or a low cut-off point at which the system becomes inefficient?

- If you have an opportunity to choose between a motor of 5 HP and one of 50 HP, which option is better suited for you?

Aside from energy consumption, it’s also important to consider how long your product takes to reach its destination and what speed profile you need from the conveyor. Energy efficiency becomes less important if you need to keep the conveyor running at full speed because of the high initial cost.

Consider Environmental Impact and Material Safety When Choosing the Coveying Solution

Your goal should be to move materials in a manner that doesn’t negatively impact the plant operating environment. Is your material flammable, and does it pose a risk of fire or explosion? Will the material cause dust particles to land on the processing equipment and facility floor?

When selecting the right conveyor system, consider if your product is the type that is sensitive to high temperatures or vibrations. Does the material have to be kept safe, clean, and contamination-free?

The open nature of the slider bed belt conveyor system and bucket elevators may allow contaminants to enter the food stream. Therefore, when the conveyed material needs to be kept as clean as possible, it is best to use an enclosed conveyor that doesn’t expose the materials to impurities that may affect their quality.

Count on the Must-Have Cleaning and Maintenance

Remember that your food manufacturing facility and the conveyor you install should be designed to minimize contamination. This will allow you to achieve food and safety compliance. When comparing different conveyors, think about how much time will be spent disassembling and cleaning the system. Generally, conveyors with fewer joints are easier to clean.

You should consider your options carefully to maximize hygiene levels while minimizing maintenance costs for both plant equipment and transportation systems. Some inexpensive conveyor engineering systems might sound like a good deal at the moment. But how much will it cost you in the long run when you have to invest in extensive repairs and cleaning, pay for product loss due to breakage, or struggle with regulatory compliance?

Evaluate the Cost and Significance of Long-Term Investment

The cost will always play one of the biggest roles when it comes to choosing conveyor systems. However, short-term savings on an inexpensive conveyor, like a conveyor belt system, auger, or vacuum, are quickly offset by wastage or breakage of valuable materials. It becomes a choice of “pay now or pay later.” A conveyor that is cheap today will cost you a lot more further down the line.

Ultimately, it’s best to invest in the right piece of equipment, such as an automated conveyor system now, rather than suffer the consequences later. A low-priced conveyor may even cost you your business, particularly if it becomes the reason why you can’t comply with health and safety rules and regulations.

Ensure the Chosen System Meets Your Business Goals

When choosing the right conveyor for your facilities, don’t lose sight of why you’re doing it in the first place – to improve productivity and meet your business goals. Think about the purpose of the conveying system, how it will be used, and what you want from it as a company. Will it help increase productivity? Does the material have to adhere to certain quality standards? Are there specific regulations that need to be met when handling this product? Is space an issue?

When you know what the conveyor system is meant to do, your choice will become much simpler. You can reject options that don’t meet your objectives and choose something that suits them perfectly. This way, you’ll not only have an efficient conveyor, such as an automatic conveyor system, but also one that doesn’t cost too much in terms of time and money.

Cablevey Conveyors Have Numerous Top-Notch Options for You to Choose From

To ensure you get a high return on investment, conveyor selection must be made with key considerations in mind. For example, you need to think of the product type, the weight of your products, available facility space, environmental conditions, and cleaning and maintenance resources.

And while cost should also be considered, it’s still better to invest in the right material handling equipment now rather than suffer the consequences later. The wrong conveyor system can lead to injury and accidents, product loss, and failure to observe protocols enforced by regulating agencies that allow you to stay in business.We know this choice can be a bit overwhelming, so don’t hesitate to contact our experts at Cablevey Conveyors. Our expertise encompasses a range of solutions, including both belt conveyors and more advanced automated conveyor systems, ensuring tailored and efficient material handling solutions for your unique needs.