Numerous types of grains can be used in the food processing industry. Among them, specialty grains are quite popular thanks to their excellent characteristics. So, what are commonly used specialty grains in food processing? Keep reading to learn more about these materials and their benefits.

What Are Commonly Used Specialty Grains in Food Processing?

In the food processing industry, many different types of grains can be used to create a variety of products. Bulk grains are those that are processed in larger quantities. Commonly, these are wheat, corn, and soybeans. Depending on the end product, bulk grains usually don’t have to be handled too gently (this goes for corn flour, white flour, or pet food, for example).

However, there are also specialty grains that are often more delicate. These fragile materials include oats, rye, quinoa, barley, millet, rice, and amaranth. Specialty grains are typically used to create snack foods such as granola bars, or they can be packaged for home cooking.

Specialty grains are more expensive and need to be gently handled as they cannot be broken during food processing. Let’s go over these unique ingredients in greater detail so we can learn about their characteristics and processing requirements.

Oats – Highly Nutritional Material With Many Benefits

In 2020, more than 25 million metric tons of oats were produced worldwide. Oats are highly nutritious cereal grains commonly used in foods such as breakfast cereals and pancakes. They contain a high amount of soluble fiber, an excellent lipid profile, and are considered gluten-free.

The grain itself has a soft outer layer, which means that conveying it on a belt conveyor system can be difficult. To avoid breakage, oats are typically ground into a fine powder (refined flour) before being mixed with other ingredients to create a final product.

However, not all food processors grind their oats. Those who want to preserve the whole grain texture require gentle bulk material handling equipment that keeps the grains intact throughout processing. Oats can come in various forms: steel-cut oats, rolled oats, oat flour, and oat bran.

Rye – An Excellent Alternative to Wheat

Similar to oats, rye is a significant source of dietary fiber. Different studies have confirmed that rye causes a much lower insulin response than refined wheat (white wheat flour). Therefore, rye is a great alternative for people with diabetes and those trying to lose weight. Whole-grain rye products have good satiating properties. Studies suggest that this is due to the porous structure of the grain.

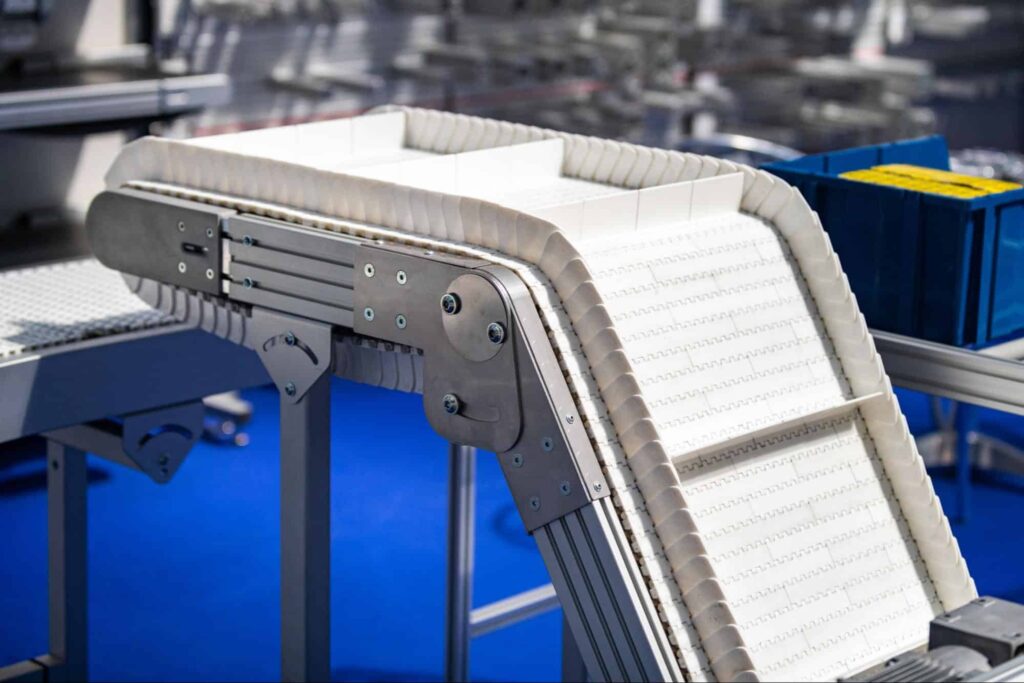

However, this porous structure is challenging to maintain during processing. An industrial conveyor belt for food that can handle the grain without breaking it is crucial to keep product quality high. When it comes to forms during food processing, rye can come in the form of rye berries (whole rye kernels), cracked rye or rye chops (equivalent to steel-cut oats), rye flakes (equivalent to rolled oats), and rye flour.

Quinoa – Gluten-Free Seed With High Protein Content

Technically, quinoa is a seed and not a grain. Nutritionists tend to group it with whole grains because of its high protein content. The nutritional benefits of quinoa include compounds such as several B vitamins, magnesium, phosphorus, and other nutrients. Besides being used for baking purposes, quinoa can be ground into flour to create gluten-free baked goods.

Additionally, quinoa seeds are often packaged and sold as whole grains. Handling the seeds with care is crucial to maintaining their quality. This is especially true after the seeds undergo the process of drying to avoid germination. The dry, brittle nature of quinoa seeds makes it difficult for them to pass through a typical conveying system. To avoid breaking the seeds during food processing, the material must be handled with care in an enclosed system that doesn’t expose them to the environment.

Barley – A Grain Used for Producing Various Types of Food

Barley is most commonly used for brewing beer and beer production. However, it is also used to create energy drinks and other foods like cereal bars or pasta. It is rich in vitamin B, as well as iron and manganese. When barley kernels pass through a conveying system with strong vibrations, they can easily break into pieces and lower their value as an ingredient for food processing purposes.

As a whole grain, barley requires gentle material handling systems that don’t expose the grains to harsh environments like high-temperature conveying lines. Otherwise, they will become too brittle, leading to product loss and compromised product quality. Barley can be processed into barley flour, but also other products such as barley flakes and grits.

Millet – Another Excellent Wheat Alternative

Millet is an important food crop used mainly in Asia and Africa, especially in Nigeria, Mali, and India. It is one of the world’s ancient grains and has been used for food production for millennia. Millet can be cooked like rice or quinoa to create a gluten-free alternative for people with celiac disease who cannot eat wheat products such as bread and pasta. Manufacturers use millet to create gluten-free products such as breakfast cereals, baking mixes, and snacks.

This Grain Is Fragile and Should Be Processed in Gentle Conveyors

A millet is a fragile specialty grain that easily breaks into pieces when coming in contact with other grains or during processing. Therefore, it should be handled carefully throughout the conveying process – especially since most systems expose these small particles directly to high temperatures. Luckily, conveying systems that can handle millet without exposing it to environmental factors are available – such as tubular drag cable conveyors. These systems help maintain the delicate nature of millet and avoid product loss or compromised quality.

Rice – One of the Most Popular Specialty Grains

As a grain, rice is highly versatile. White rice, brown rice, wild rice, and others can be processed into a wide variety of different products, from rice flour to pasta. It is one of the most popular grains and is most commonly conveyed as a raw material, but in some parts of the world, parboiled rice can be found as well. Parboiled rice is processed under high pressure and temperature, making it easier to process into various food products.

In all of its forms, rice requires gentle handling throughout the conveying system – especially since it is a delicately shaped grain that can easily break during processing. Mechanical conveyors that are the best choice for conveying rice are those that expose the product to little environmental factors and don’t generate vibrations. Using adequate conveyors minimizes damage to the delicate nature of rice, making it easier for manufacturers to process it into a wide variety of products.

Amaranth – A Pseudocereal That’s Rich in Amino Acid Lysine

Amaranth plants are classified as pseudocereals (non-grain used in the same way as grains) because they are used to make the same types of products as cereals. The yield of amaranth grain is similar to maize or rice. Amaranth grains are processed into flour for use in baked goods such as bread or cakes. They are rich in protein, especially the amino acid lysine, which is not found in other grains.

Amaranth Can Be Conveyed via Several Different Conveyor Systems

Like all the other specialty grains on our list, amaranth should be carefully conveyed to minimize product loss and quality issues. Amaranth is usually processed by pneumatic conveyor systems or a custom conveyor belt system that can move the delicate grain from one location to another without coming in contact with other products that could damage it.

However, both pneumatic and belt conveyors are not ideal for various reasons. A belt conveyor can generate high-frequency vibrations that could damage the grain. A pneumatic system requires careful control to avoid putting too much pressure on the delicate grains, or they will break into pieces.

For these reasons, tubular drag cable systems are recommended for conveying amaranth from one location to another. Amaranth can also be processed into flakes for use as an ingredient in breakfast cereals or baked goods – but these should also be conveyed using a gentle system that minimizes exposure to environmental factors.

What Are the Most Popular Specialty Grain Industry Trends?

All across the globe, the demand for replacements for commonly used grains such as wheat keeps growing. The primary reason is that consumers are looking for gluten-free options and grains that provide high protein content – or even a combination of the two traits. Statistics confirm that, in the United States, whole grain consumption has been steadily rising, with approximately 95% of people now eating it on a daily basis. This is especially true among younger generations who are looking for healthier alternative grains.

Replacing Common Grains With Specialty Ones and Investing in New Food Processing Technologies

Based on trends in human consumption of grains, it is very likely that manufacturers will look towards replacing common grains with specialty ones such as rye, quinoa, and amaranth in the future. Manufacturers have increased their production capacity by investing in various new technologies and equipment, such as conveying systems. The goal of this investment is to reduce costs and improve product quality and safety. Consumers will benefit from these advancements in food processing technology by being able to enjoy more high-quality products.

Cablevey Conveyors Provides Top Quality Conveying Systems for Specialty Grain Processing

Many specialty grains require unique handling systems – both during processing and conveying. Systems like tubular drag cable conveyors minimize the risk of damage or loss by exposing products to little environmental factors throughout each step of the process.

To learn more about how they can be applied in your facility or business – don’t hesitate to contact us at Cablevey Conveyors! Our conveying systems are ideal for minimizing product loss and maximizing the quality of specialty grains in food processing. From a standard conveyor belt for a warehouse to the top-notch tubular conveyors, we have it all. Get in touch with us and improve your production process with our outstanding equipment.

FAQ

What Are the Commonly Used Specialty Grains in Food Processing?

Specialty grains in food processing include oats, rye, quinoa, barley, millet, rice, and amaranth. These are often delicate and need gentle handling during food processing to maintain their quality. They’re popular in snack foods or as packaged items for home cooking, given their unique characteristics and health benefits.

Why Are Specialty Grains Considered Fragile Materials in Food Processing?

Specialty grains are structurally delicate. This means that during processing, such as conveying, there’s a high risk of breakage or damage. These grains require extra care throughout the processing stages to ensure that their quality is preserved, making them different from bulk grains like wheat or corn.

What Makes Quinoa Different From Other Grains?

Quinoa stands out because it’s technically a seed, not a grain. It’s grouped with grains due to its impressive protein content. Quinoa’s uniqueness extends to processing – its seeds require meticulous care, especially post-drying, to ensure quality preservation.

How Does the Porous Structure of Rye Affect Its Processing?

Rye possesses a porous structure that presents processing challenges. To maintain the grain’s quality, it’s vital to handle it with care. This porousness necessitates the use of specialized equipment, ensuring the grain doesn’t break, preserving its natural benefits and quality during processing.

Why Is Millet Considered a Good Wheat Alternative?

Millet is prized as a gluten-free substitute for wheat, making it ideal for those with celiac disease. Manufacturers use it in a variety of products, from cereals to baking mixes. It’s an ancient grain primarily used in Asia and Africa, and its nutritional benefits position it as a robust alternative to wheat.

What Are the Current Trends in the Specialty Grain Industry?

Globally, consumers are shifting towards specialty grains, seeking healthier and gluten-free alternatives to common grains. There’s a growing preference, especially among younger generations, for grains like rye, quinoa, and amaranth. This trend is reflected in the increasing daily consumption of whole grains, particularly in the United States.

How Does Cablevey Conveyors Assist in Specialty Grain Processing?

Cablevey Conveyors offers specialized conveying systems, like tubular drag cable conveyors, optimized for specialty grains. These systems prioritize minimal product loss and reduced environmental exposure, ensuring grain quality remains uncompromised. From standard belts to advanced tubular systems, Cablevey Conveyors caters to diverse processing needs.